Precision and Passion: The Heart of Pattern Cut’s Success Story

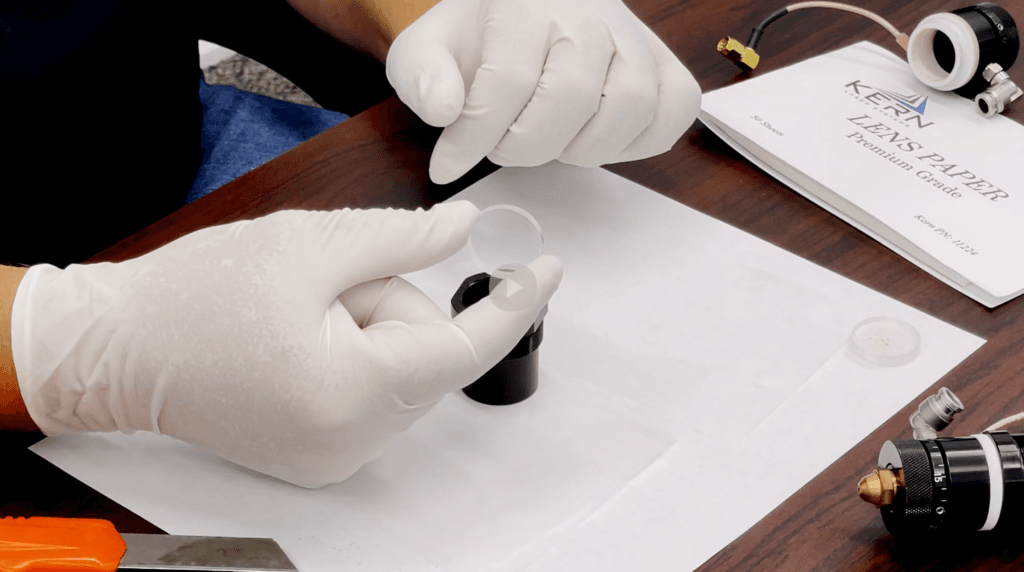

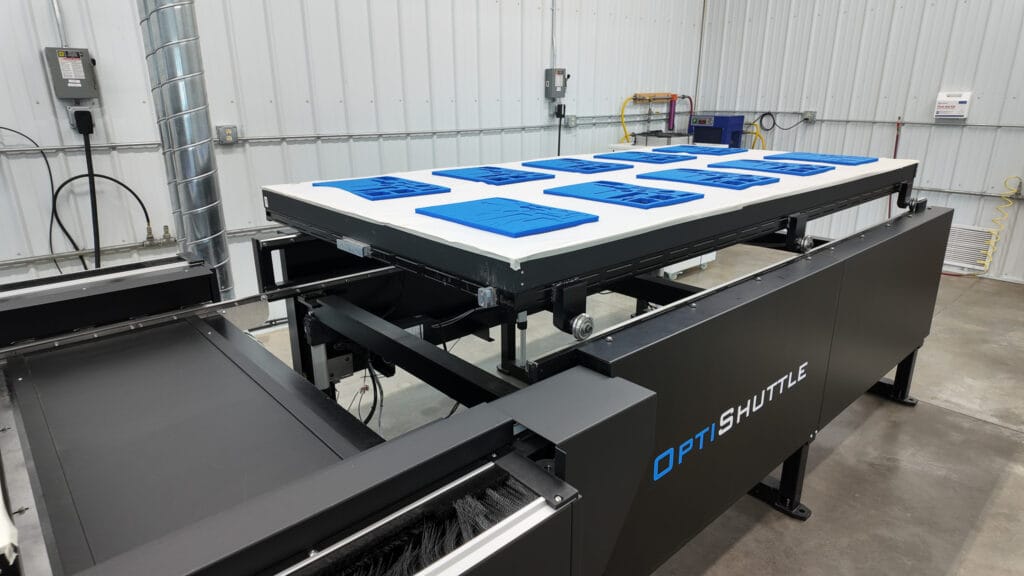

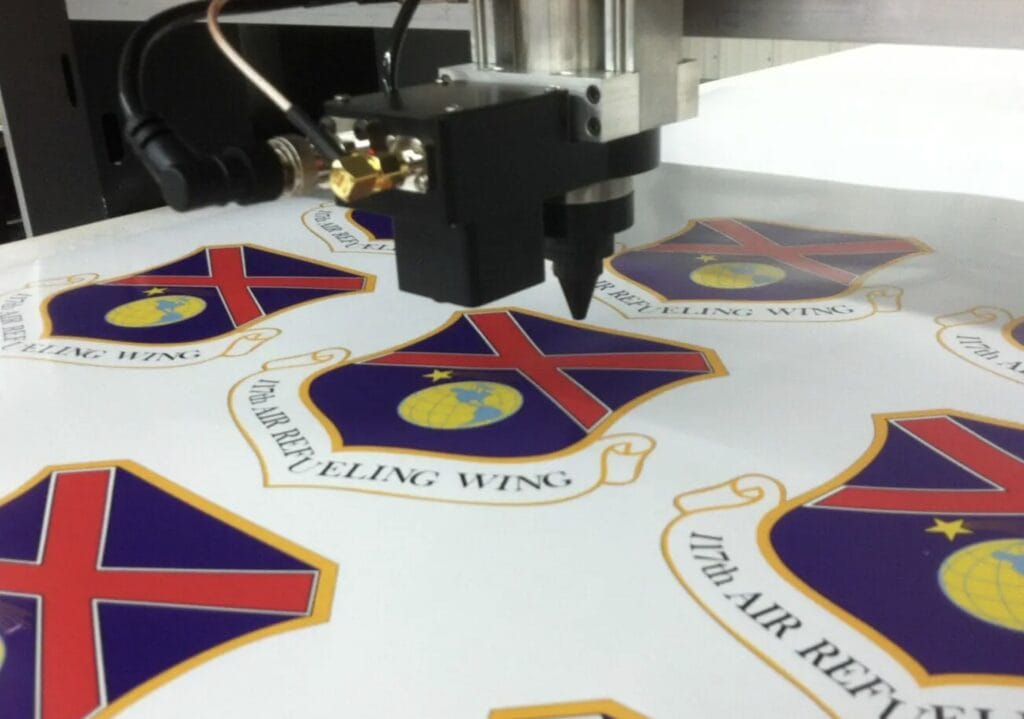

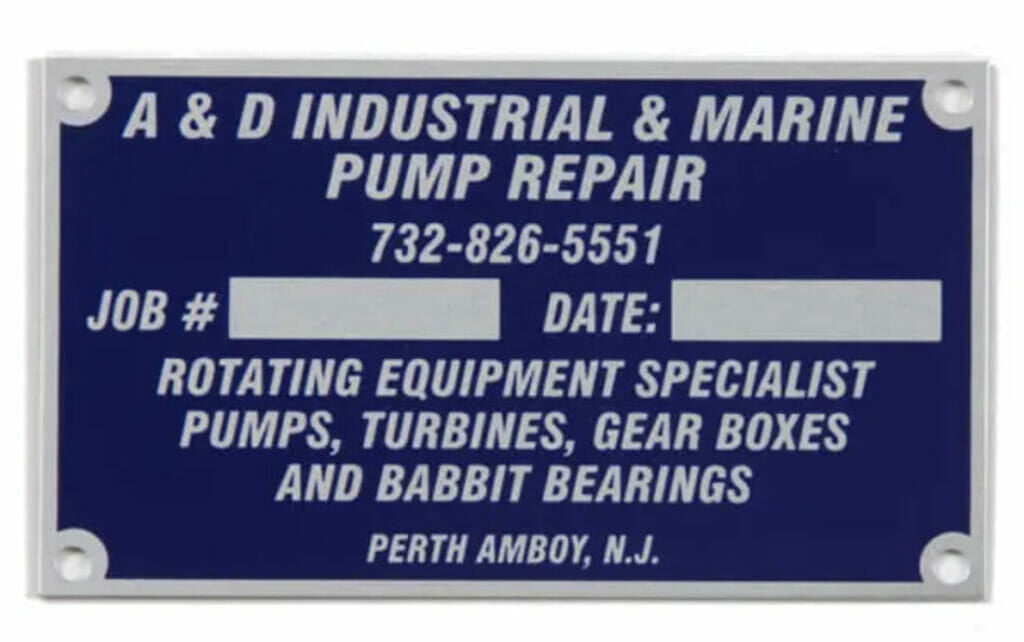

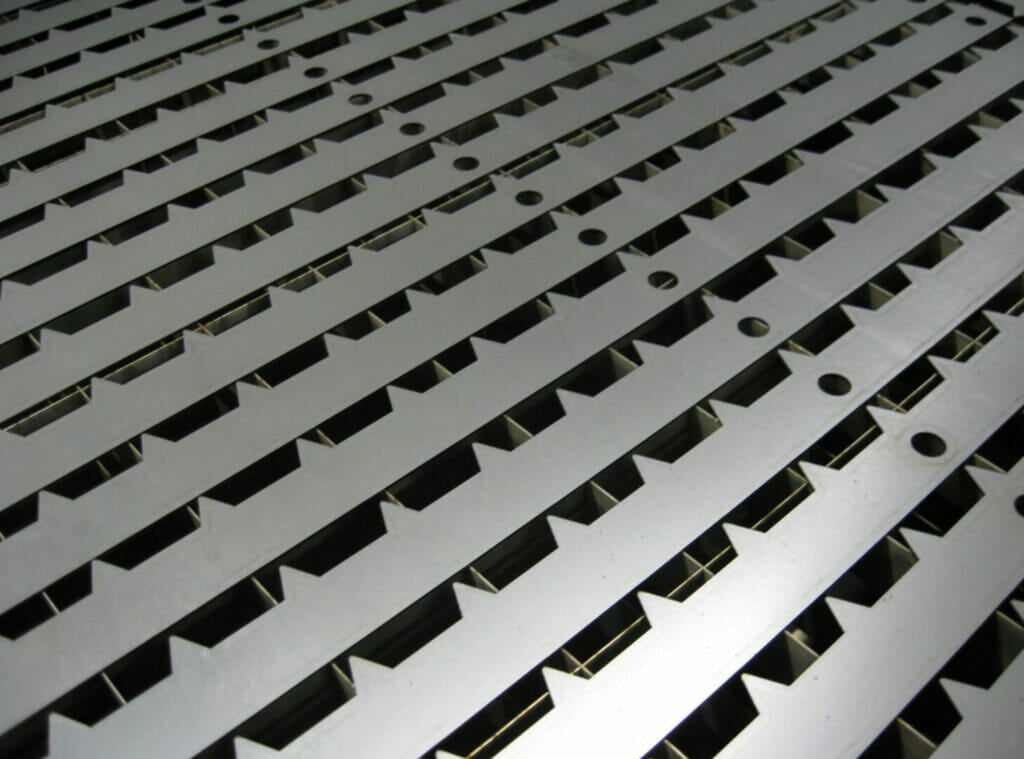

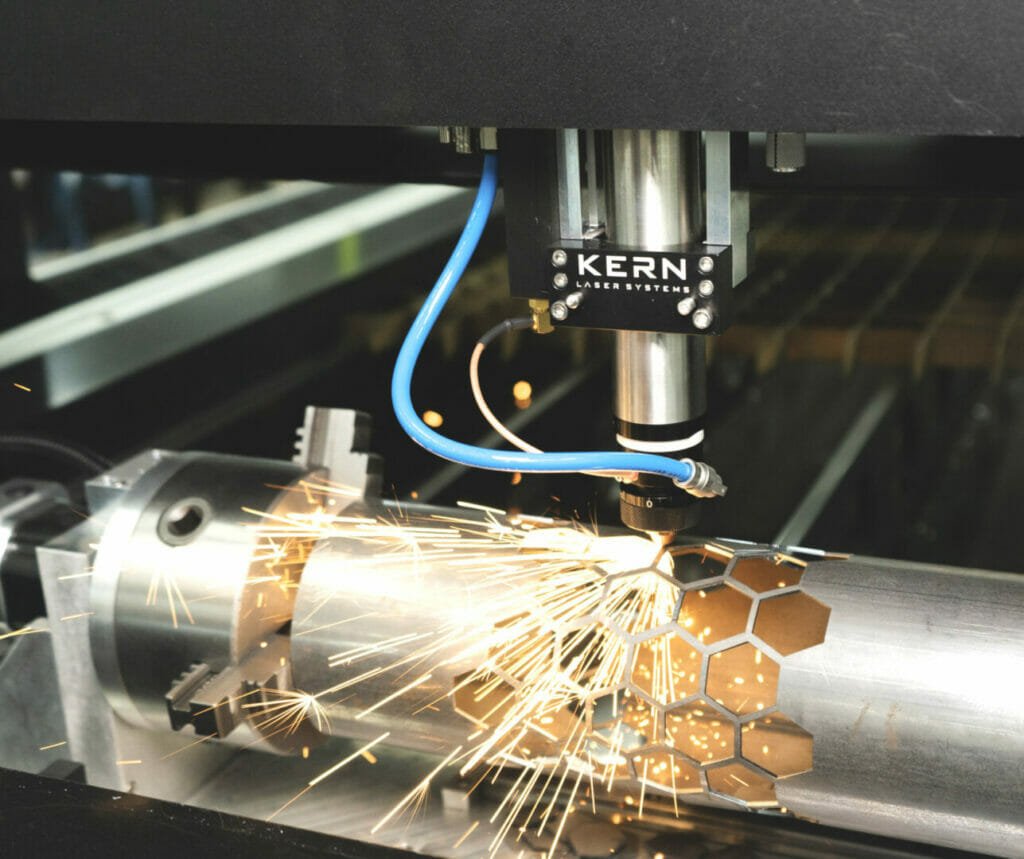

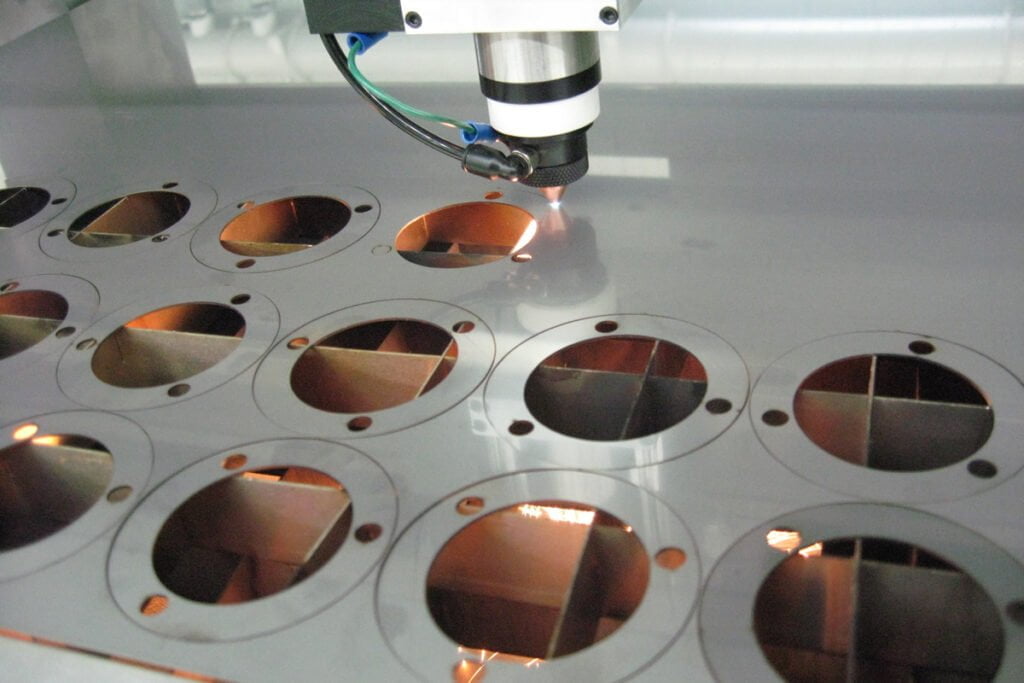

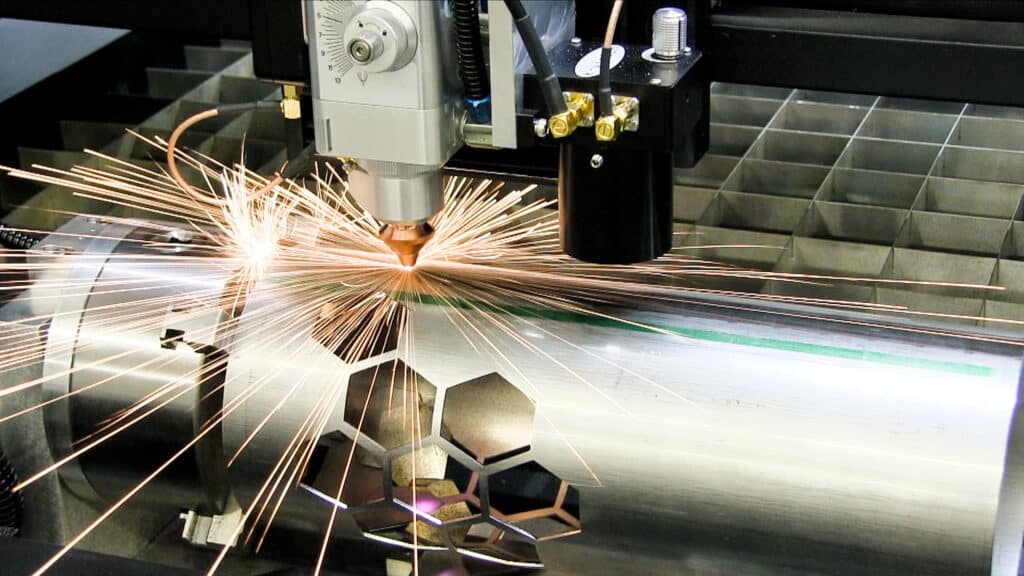

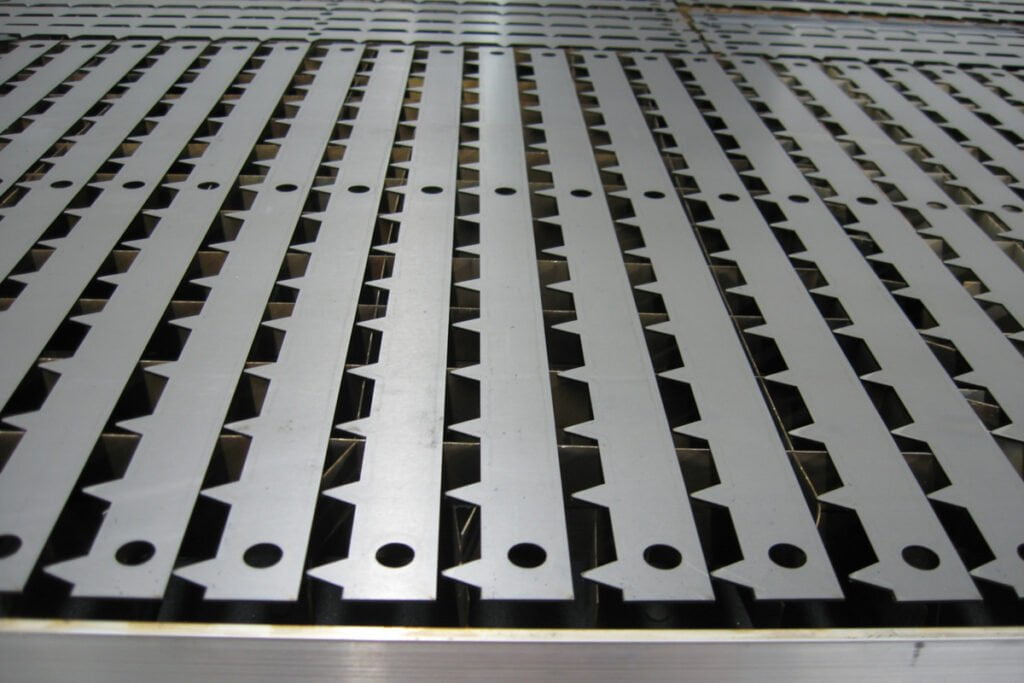

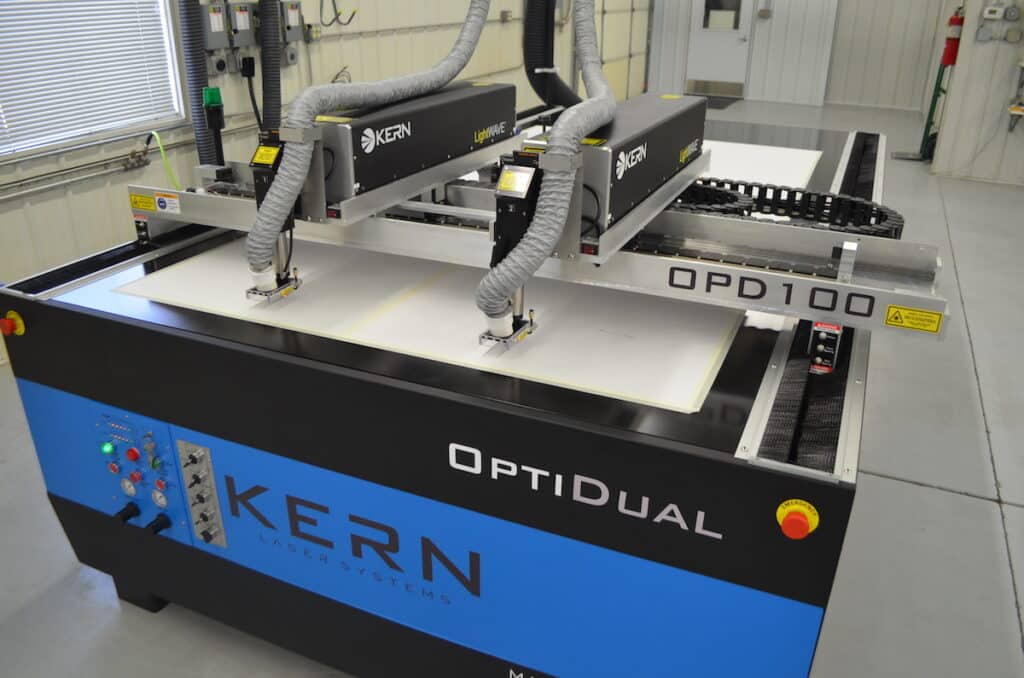

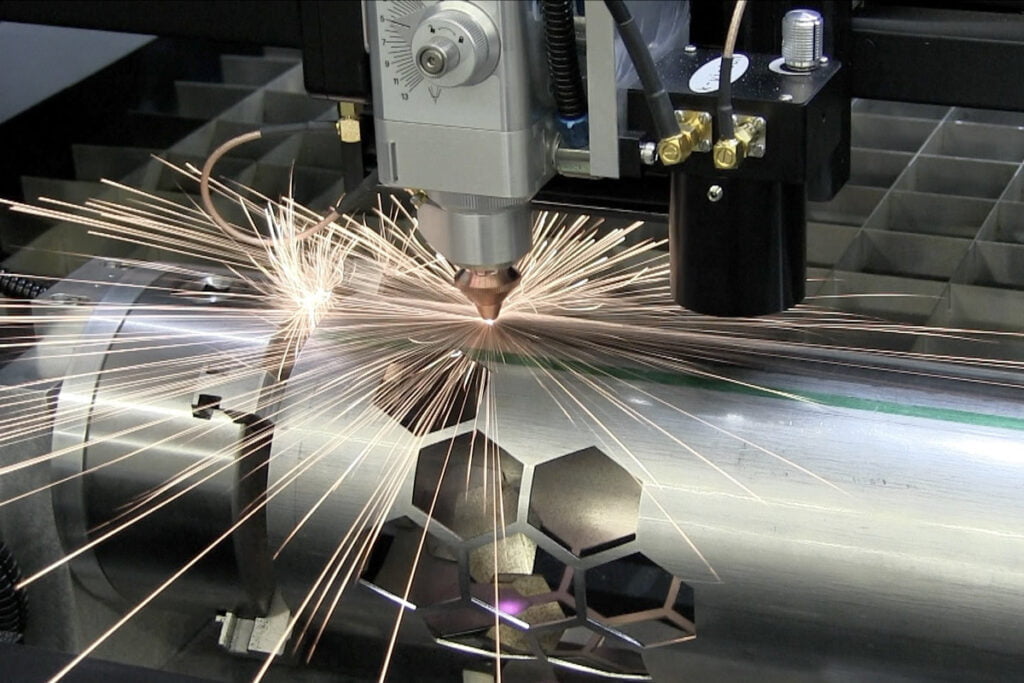

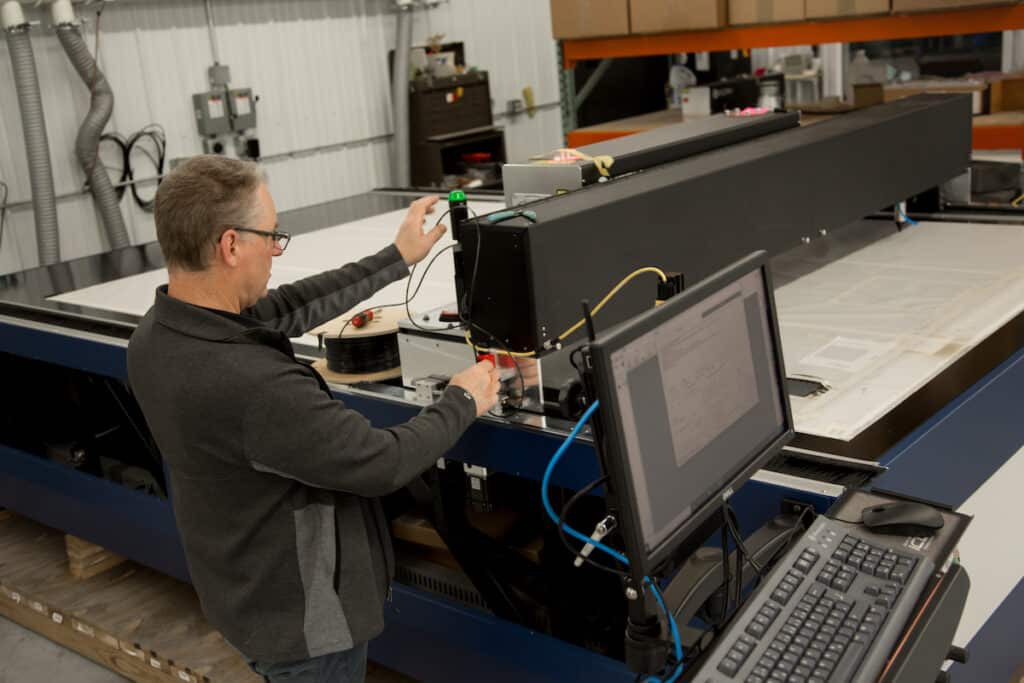

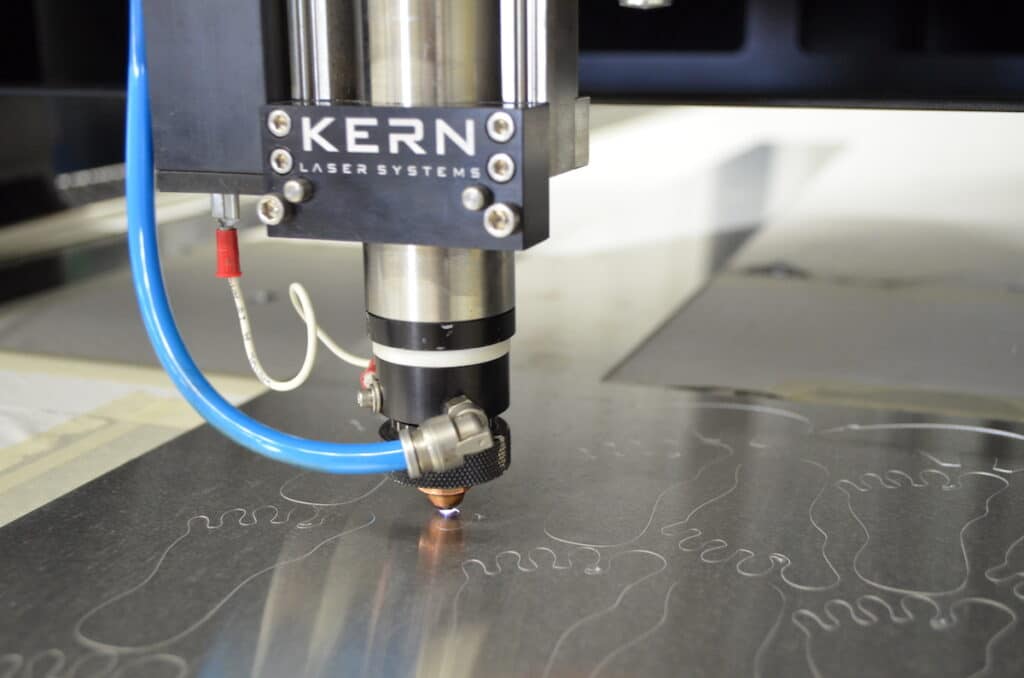

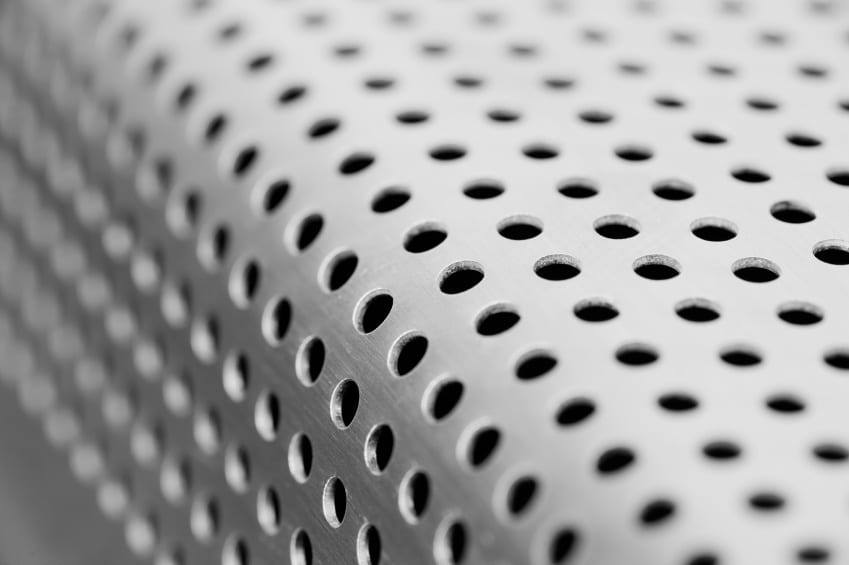

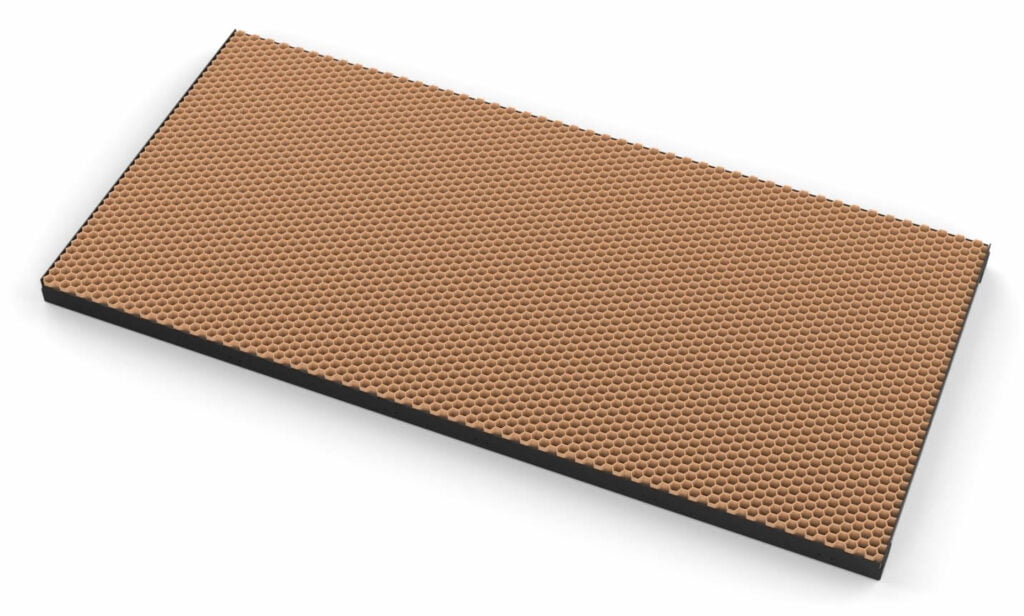

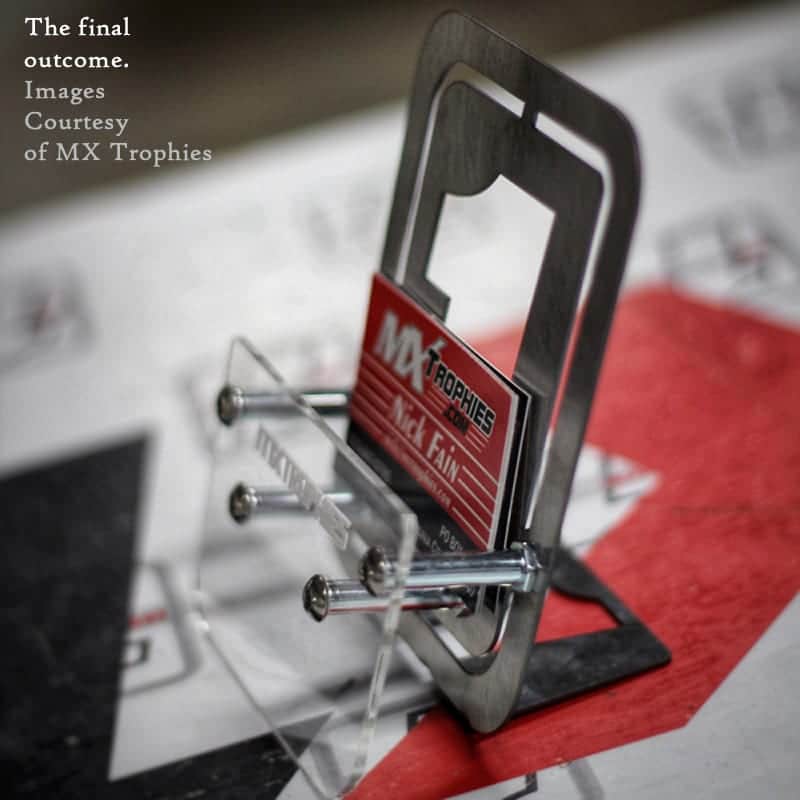

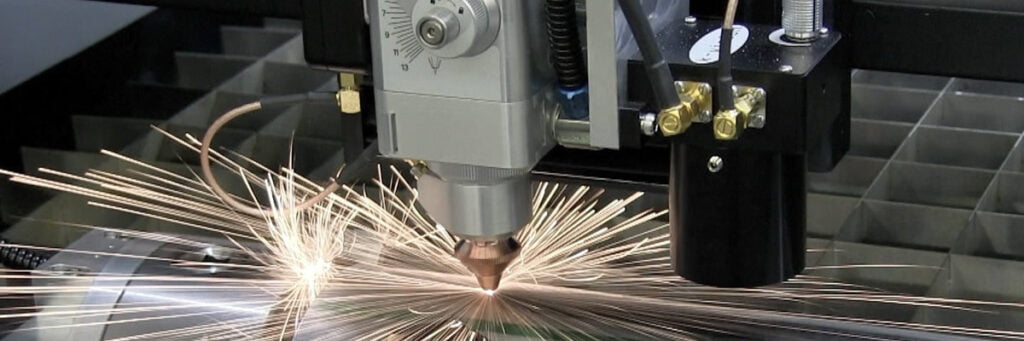

Founded in 2002, Pattern Cut Inc. creates premium laser-cut products, including cabinet grilles, doorway arches, and HVAC covers, with a focus on sleek, drywall-integrated designs. They serve residential, hospitality, and commercial sectors, with notable clients like Disney, Stanford University, and The Plaza Hotel. Learn how Leigh Freedman, CEO of Pattern Cut, transformed his growing business with the help of Kern Laser Systems