Laser engraving can take some getting used to. Even seasoned operators will find themselves confronted with the occasional head-scratcher during a laser engraving project. Below, I’ve outlined a handful of laser engraving tips and techniques to help you avoid costly mistakes.

What are some of the common mistakes laser owners and operators make that end up costing them in the long-run? Here are four laser engraving mistakes to avoid.

WRONG AIR PRESSURE

Setting the proper optic air pressure when cutting metal is a very important step, and you will notice the negative effects of incorrect air pressure almost instantly.

When it comes to engraving, air pressure commonly gets overlooked as most materials are much more forgiving, and the air pressure setting is not critical. However, there are certain engraving and etching applications where setting the air pressure correctly is key.

One of these applications is plastic etching—such as an acrylic sheet. Using a higher optic pressure through a small nozzle concentrates the air flow onto the area being processed and can leave a hazy ghosting or shadowing effect around the etched area. By simply decreasing the air pressure you might see a decrease in this effect immediately. Don’t turn off the air completely, as you do need some positive pressure to keep smoke from entering the beam delivery.

Another tip to go along with this is using a wider nozzle opening. Kern offers a wide nozzle that can be added to any S-FOCUS assembly.

SKIPPING THE TEST RUN

Before diving into a new project, it pays to run a little test cut on an excess piece of material, even when you’re relying on presets. The fact of the matter is, you never truly know what the final result will be until you see it. Material variation is a common problem especially in wood and stone.

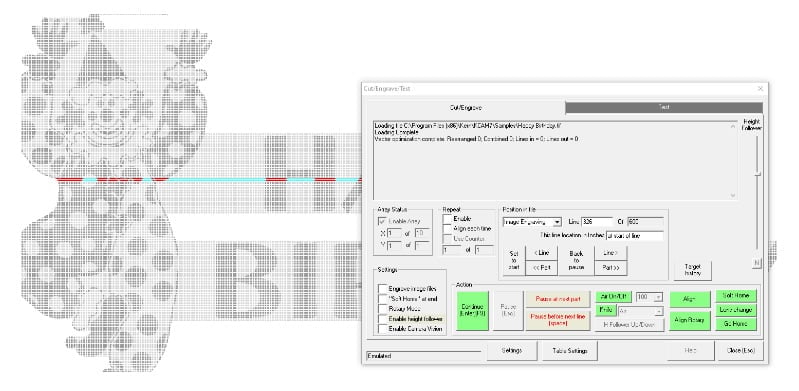

One tip here is using a neat feature in our KCAM laser software. The “Position in File” feature allows you to move to any engraving line in your project. If there is a more critical area of your engraving with lots of detail, you can simply type in that line and the laser will start at that point. KCAM makes it easy and highlights the line you type in so you can get to the line you are looking for easily.

Notice the red and cyan line across the engraving file below. Generally, an inch or two of engraving will give you a good idea if your settings are correct.

TREATING ALL MATERIALS THE SAME

Laser engraving leather is going to be different from laser engraving glass. And the same thing goes for engraving acrylic or wood. These materials are all different, and those differences impact how they respond to laser engraving.

Taking the same approach to laser engraving regardless of material types is a recipe for disaster. There is no one-size-fits-all to laser engraving, because the variables—and possibilities—are endless.

The KCAM software accompanying your laser system includes the ability to save your settings in a directory for future use. This works great for customers that process the same materials on a regular interval. Simply load in the settings file and you are back to the same great settings you were using a month ago on the same material. This helps to maintain consistent engraving from job to job, and it helps reduce startup time for each project.

Over time, your settings directory will become one of the most important parts of your system!

FORGETTING TO CLEAN YOUR MACHINE

Are you noticing your laser engraver’s performance is slower than it used to be? It might be time to give your machine a thorough cleaning, with special attention to the optics. Like any piece of equipment or machinery, laser engraving machines require routine maintenance.

Depending on the materials you are engraving, dust and debris buildup may be a frequent problem. It is important to make sure your vacuum blower system is running efficiently. Ensure there is not build up in your vacuum hose lines and smoke/dust is quickly being picked up by the vacuum ports. As always, check your operator’s manual for tips on cleaning your machine and other maintenance specifications, especially if you’re noticing a sharp decline in processing speed.

One common mistake I see is when customers are using a known good setting but for some reason they are not getting the results they did previously. Most users instinctively increase the laser power to get back to the proper setting. However, most times that is the last thing you want to do. The best solution is to determine what is causing the drop in power. It could be a dirty optic that just needs a good cleaning. If you ignore these warning signs, the increase in power will only heat up the optic more and eventually it will crack.

For customized laser engraving tips and techniques, you can always connect with the team at Kern Laser Systems to discuss your approach to engraving. Oftentimes, it comes down to understanding your material, your laser system and how the two react to each other. Luckily, getting the hang of laser engraving is relatively quick and easy, especially when you have the support you need.