Play Video

Small Format / Entry Level Laser System

MICRO - Laser Cutter & Engraver

The only thing “small” about our MICRO is its table size, as it can be equipped with the same powerful CO2 lasers as our large format models. The MICRO comes standard with high-speed engraving technology and a moving Y-axis bed for fast, accurate vector cutting. The MICRO laser system is a flexible laser solution, consuming minimal floor space in your facility.

If you’d like to find out how a MICRO laser system can help your business, school or organization, please use our simple contact form or Request a Quote.

Materials

Cut | Mark | |

|---|---|---|

Acrylic | ||

Mild Steel | ||

Stainless Steel | ||

Aluminum | ||

Anodized Aluminum | ||

Brass | ||

Wood | ||

Foam | ||

Leather | ||

Stone | ||

Specifications

Imperial

Metric

Laser Classification: Class 4 CO2 Laser

Laser Wattage: 100 – 650 watts

*Positioning Accuracy: +/- 0.002″/ft

Repeatability: +/- 0.0005″/ft

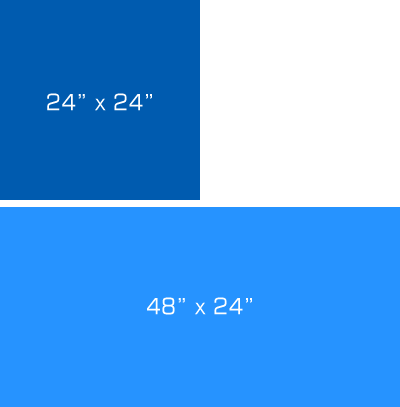

Work Area*: 24″ x 24″ or 48″ x 24″

Footprint (W x L x H): 70″ x 36″ x 56″

**Part Clearance: 3″

Electrical: 230v/1ph, 230v/3ph

*Mapped table under controlled conditions

**Custom gantry heights by request.

Laser Classification: Class 4 CO2 Laser

Laser Wattage: 100 – 650 watts

*Positioning Accuracy: +/- 0.167mm/m

Repeatability: +/- 0.0417mm/m

Work Area*: 610mm x 610mm – 1219mm x 610mm

Footprint (W x L x H): 1778mm x 914mm x 1422mm

**Part Clearance: 76.2 mm

Electrical: 230v/1ph, 230v/3ph

*Mapped Table under controlled conditions

**Custom gantry heights by request.

What Our Clients Say

Request a Quote

Case Study - Laser Etch Technologies, Buffalo, MN

Owner Tim Pawelk of “Laser Etch Technologies” roots run deep with Kern Laser Systems. A customer since 1999, Laser Etch currently uses four Kern lasers that have been instrumental in achieving worldwide attention. Such projects included teaming up with renowned Tibetan artist Rinchen Dorgee. Dorgee was instrumental in the creation of the throne the Dalai Lama used during his visit to Minneapolis/St. Paul in May of 2001. The throne was also recently used for His Holiness when he visited Minneapolis this year to celebrate the Tibetan New Year.

Around Minnesota, Tim has also done amazing work. Most notably, his wood etching and engraving can be seen in the Legends Club area located at Target Field, the home of the Minnesota Twins.

Baseball fans would recognize Pawelk’s grand slam work located at Target Field, home of the Minnesota Twins. This creative wonder that includes both etching and engraving can be seen in the Legends Club and press box areas of the stadium.

Pawelk allows that the Kern Laser Systems has provided him with the needed tools to think outside the box and grow his business through the wide range of capabilities found in a Kern laser.

Read More

He has been able to do a variety of projects with his Kern Lasers that he’s sure he wouldn’t be able to do with the use of some of the competitors’ laser systems. Some of his projects have drawn attention not only in the United States, but also worldwide. In 2001, Tim Pawlek and Laser Etch teamed up with renowned Tibetan artist Rinchen Dorgee. Rinchen was the main artist involved with the creating of the Dalai Lama’s throne his visit to the Twin Cities in May of 2001. The throne was recently used for his holiness when he visited Minneapolis this year to celebrate the Tibetan New Year.

To hear more about Laser Etch’s projects, as well as their experience with Kern Laser Systems, click on our video link for Laser Etch’s exclusive customer testimonial.

Play Video

Standard Features

Closed-Loop Chiller

A closed-loop chilling unit properly cools the laser source, ensuring a long laser lifetime and consistent cutting and engraving results.

Vacuum & Fume Exhaust

A blower package will remove fumes and small debris created during laser processing. An integrated downdraft table holds material flat on the table.

Computer Package

A high-performance computer and monitor is included with each system. An adjustable monitor arm is installed at the front corner of the machine.

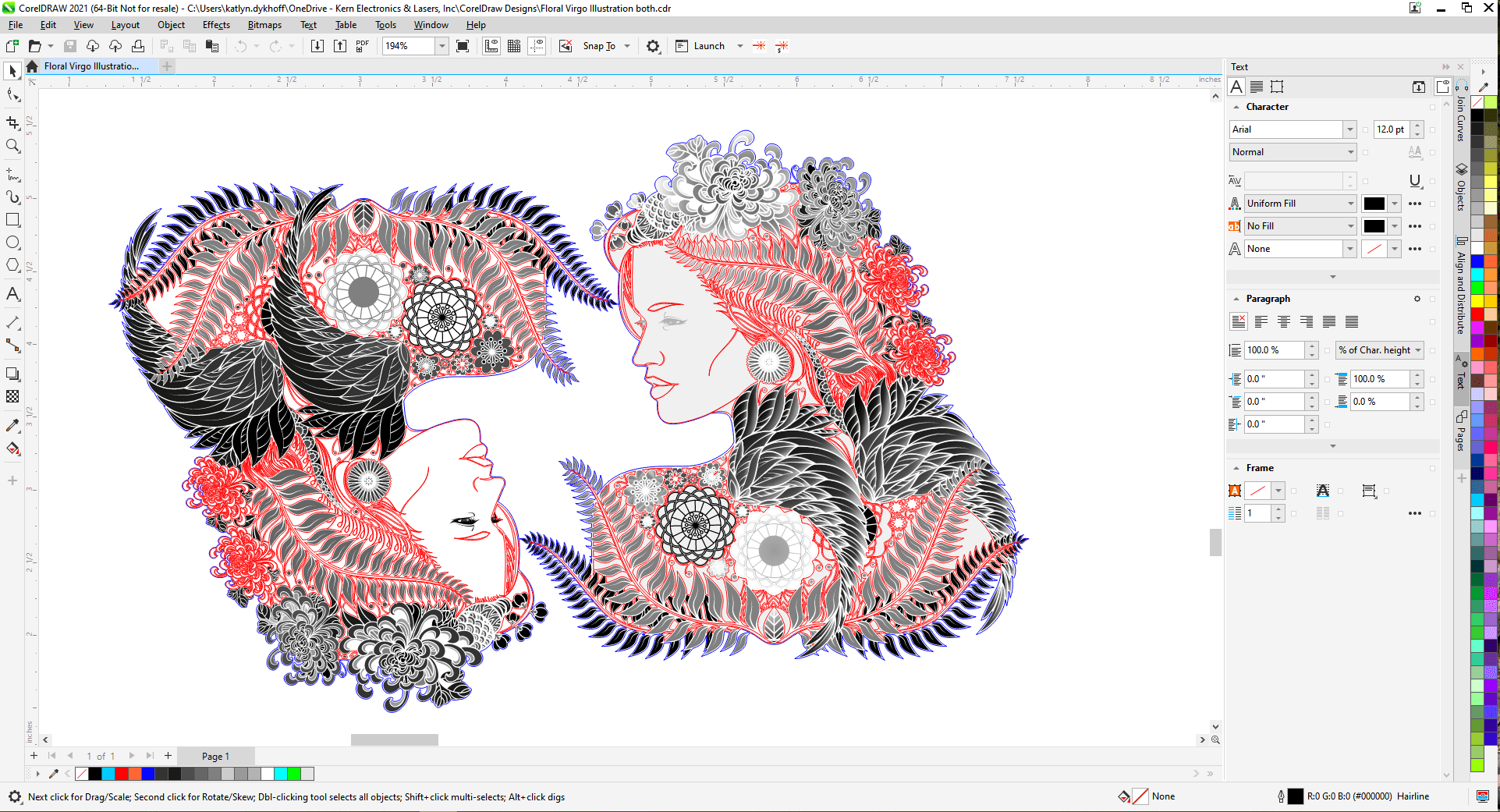

Software Package

KCAM Laser Software and CorelDRAW Graphics Suite are linked together allowing over 100 file types to be used, including .DXF, .PDF and G-CODE.

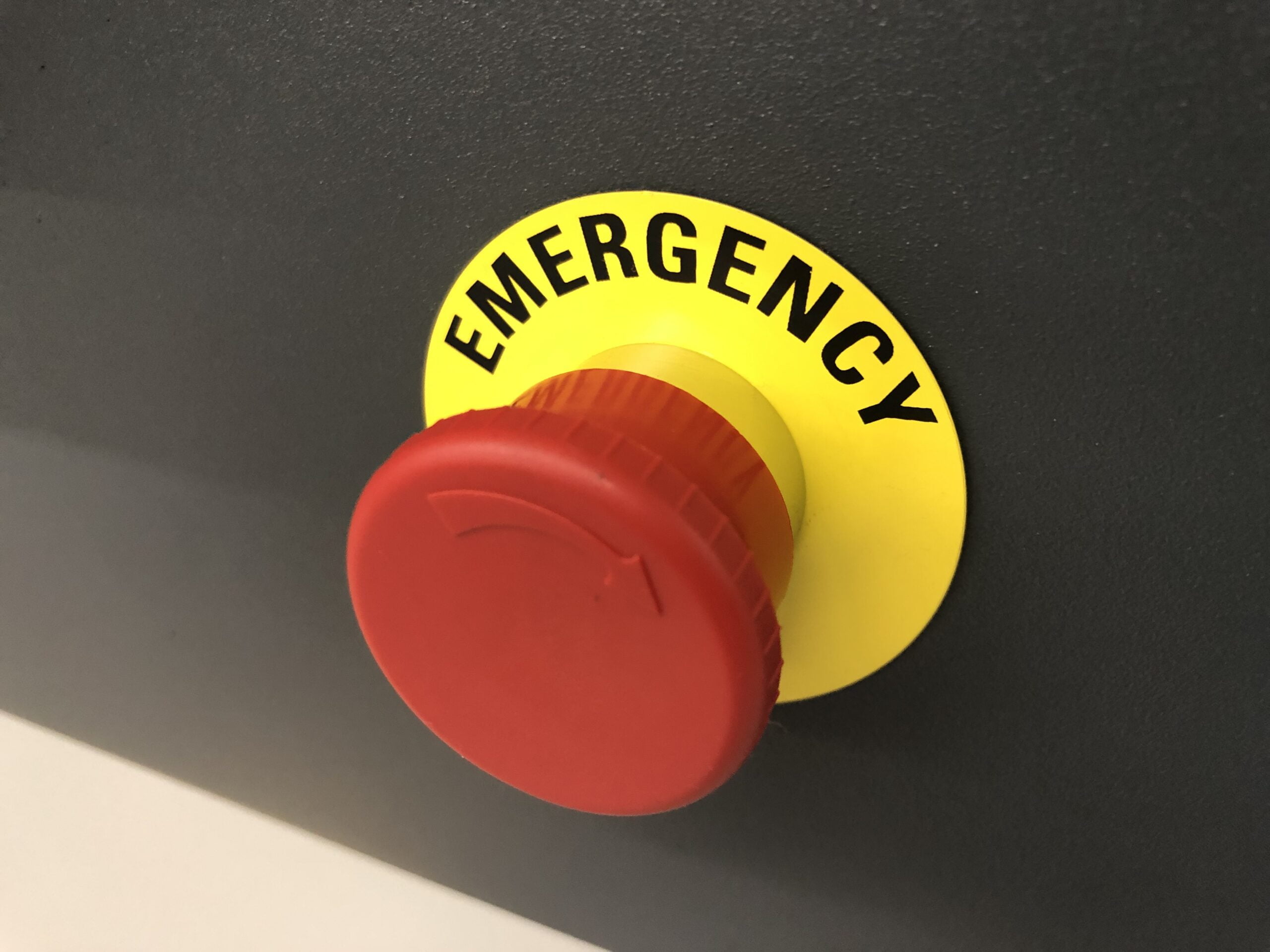

Safety Features

CDRH laser machinery compliance is ensured with emergency stop buttons, safety labeling, interlocked access points and a 5 second delay safety key switch.

Servo Motors

High-speed servo motors are installed on the EcoFlex model, providing smooth and accurate cutting and engraving performance.

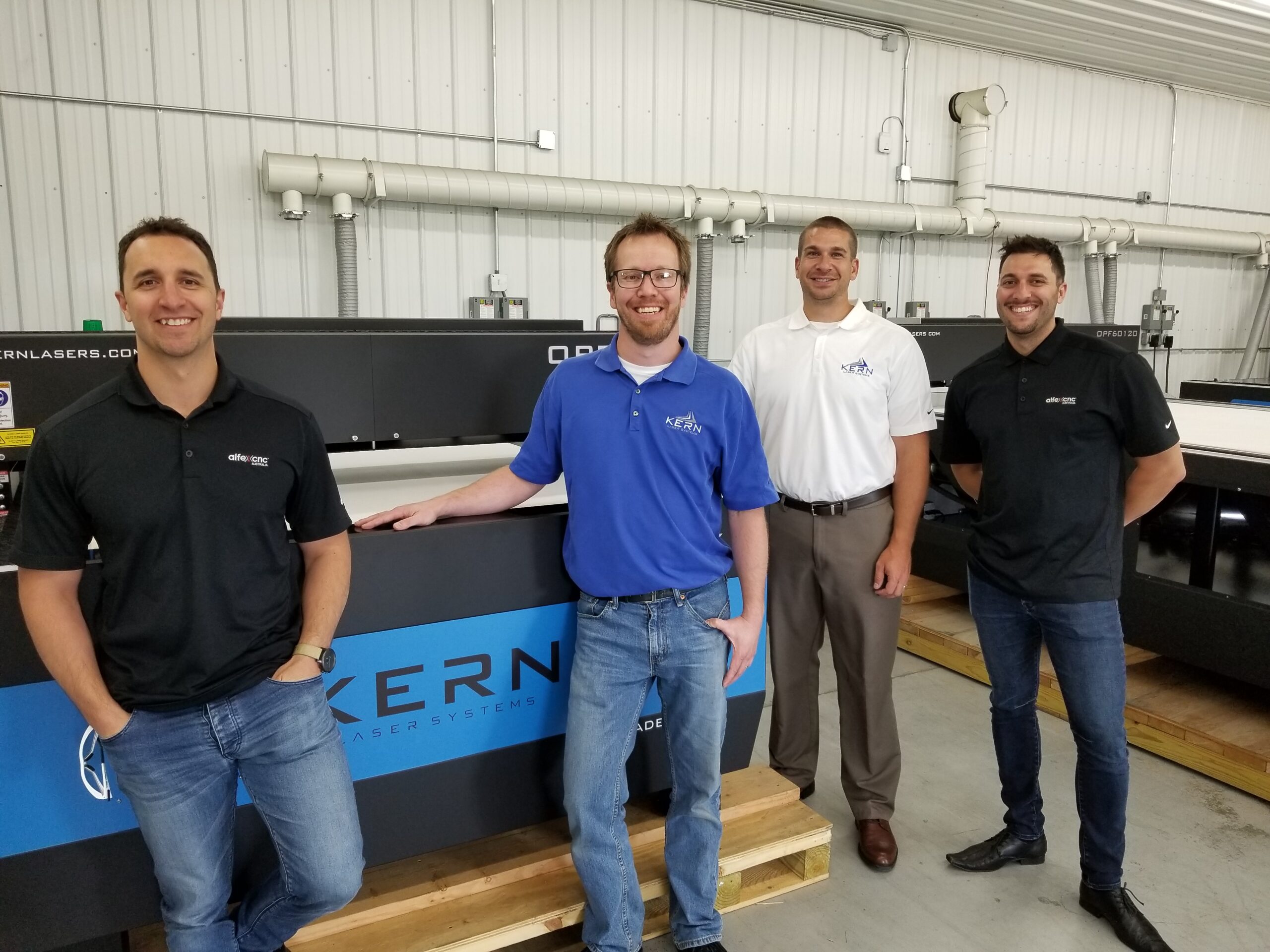

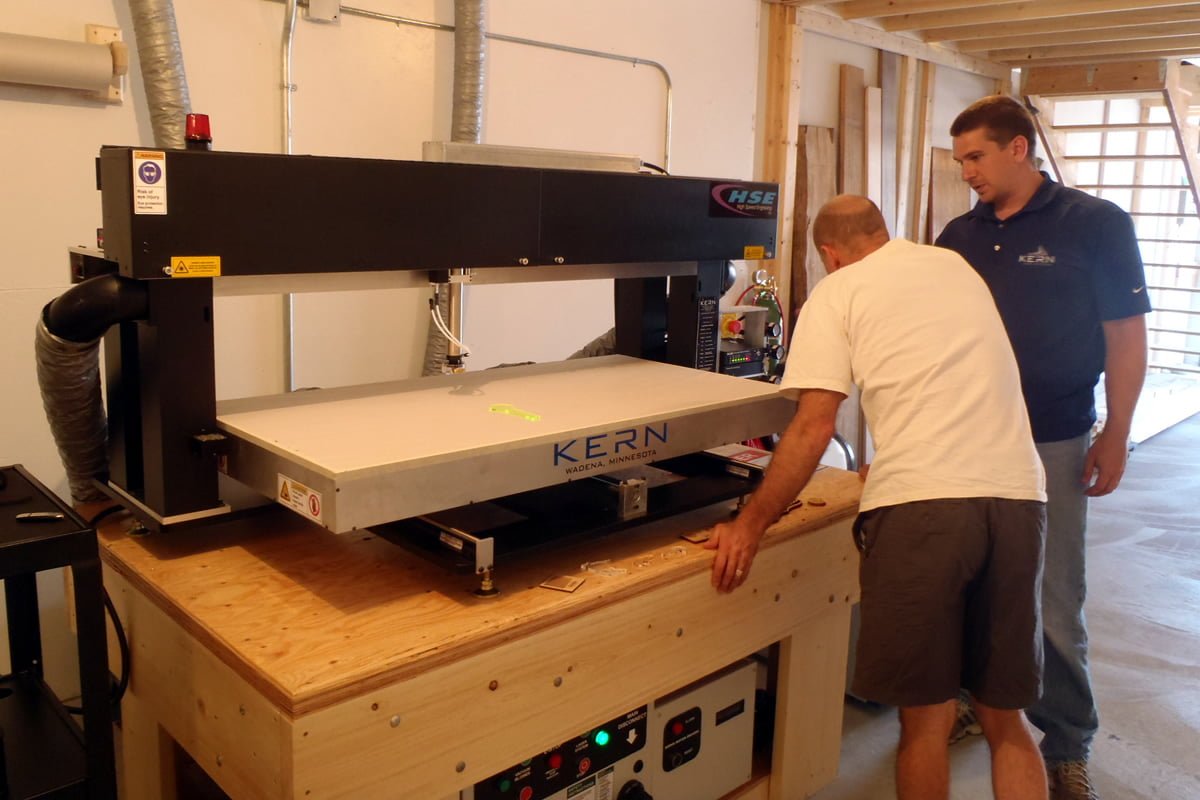

Training Program

A 2 day training course at Kern's factory is included with each system. Kern's knowledgeable staff will cover safety, maintenance, operation and applications.

Optional Packages

Metal Cutting

K-Vision Camera

Pipe Rotary Attachment

Fume Extractor

Metal Cutting

Kern’s CO2 laser format laser systems can be equipped with innovative metal cutting technology. The metal cutting option provides accurate cutting of sheet metals such as stainless steel, mild steel, aluminum, and brass.

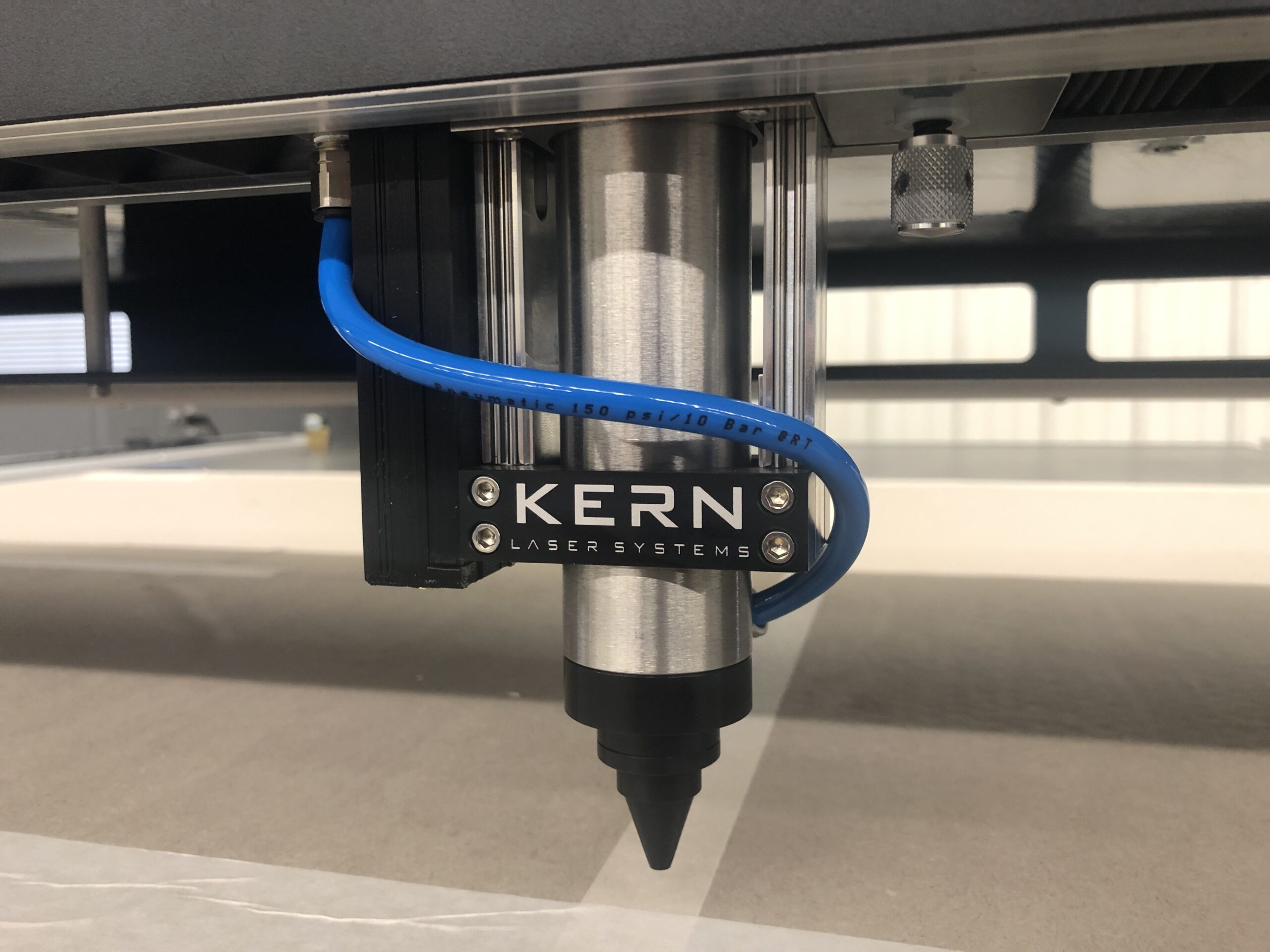

Air Assist

High Pressure assist gas, such as oxygen, CDA(clean dry air) or nitrogen, is injected through the metal cutting nozzle. The result is a dross free cut edge that requires little to no deburring.

Auto-Focusing

As the cutting process begins, the height follower tracks the surface of the metal and adjust the nozzle in the z-axis maintaining a constant focus point while the metal is being cut.

To learn more about the Metal Cutting, please watch this video and visit our Metal Cutting page.

K-Vision Camera

The K-Vision Camera package is a fully integrated hardware and software solution allowing fast and accurate cutting of printed materials.

This process starts with a nozzle mounted camera which automatically measures the dimensions between registration marks on printed materials. The system then uses these measurements and the registration marks of the original cutting file to compensate for distortion and rotation. The slight adjustments that k-vision makes to the cutting file results in a perfectly matched cutout in the material being processed. The entire camera system can be easily removed and stored in a protective box when not in use.

To learn more about the K-Vision Camera package please watch this video and visit our K-Vision Camera page.

Pipe Rotary Package

A Pipe Rotary attachment can be added to Kern’s laser systems for processing of pipes, rods and other cylindrical items. The rotary device is driven by a high-resolution servo motor, resulting in smooth and accurate cutting performance.

Two rotary styles are available; the Chuck Rotary and Wheel Rotary. Kern’s laser systems can be equipped with one or both style rotaries.

To learn more about the Pipe Rotary package, please watch this video and visit our Pipe Rotary page.

Fume Extraction

A Fume Extractor can be connected to Kern’s laser systems to remove fumes and small debris creating during laser processing. Instead of ducting the fumes to the outside, the fume extractor cleans the fumes with a series of filters and recycles the air back into the room.

An inline Spark Arrestor can be added for applications which involve metal cutting. The spark arrestor is designed to dramatically reduce the amount of sparks that enter the fume extraction duct.

To learn more about Fume Extraction packages, please review our “Let’s Talk Fumes” section on our Laser Safety page and our Laser Processing Fume Removal blog.

ADDITIONAL FEATURES

UL Electrical Panel

A UL certified electrical panel is placed on each laser system which turns on and shuts down components of the laser system. CUL and CE approved machines are available by request.

Laser Safety Glasses

Two pairs of Laservision laser safety glasses are provided which each CO2 machine. This eyewear is rated OD 6+ @ 9000-11000nm, offering protection from Kern’s full range of CO2 laser systems.

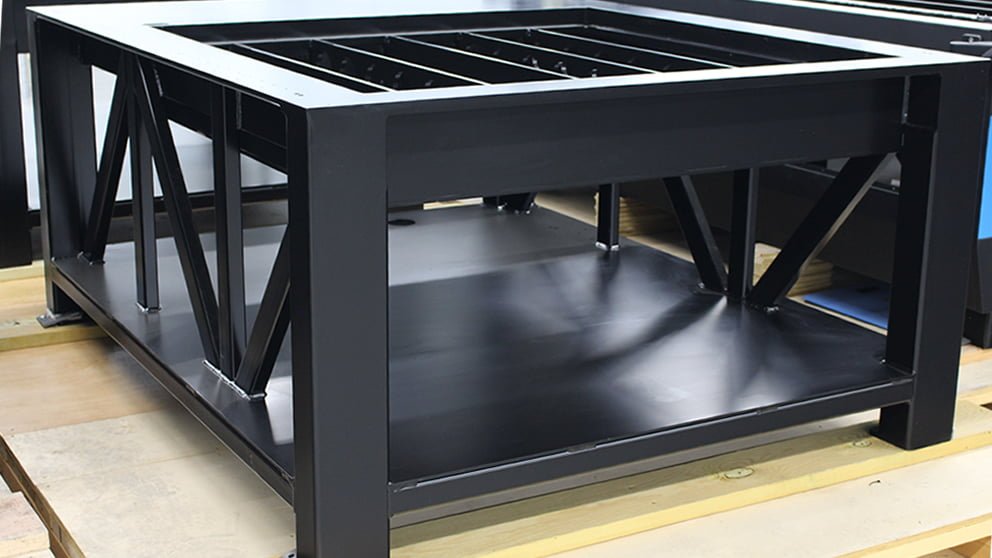

Solid Steel Chassis

The MICRO is built around a precision-machined, heavy-duty steel weldment as the machine base. The one-piece weldment allows for the machine to arrive fully assembled, greatly reducing installation time.

2.5” S-FOCUS Lens Assembly

A great all-around processing head equipped with a high-quality optic. The assembly features an assist air which pushes air out of the nozzle, protecting the lens from smoke and debris.

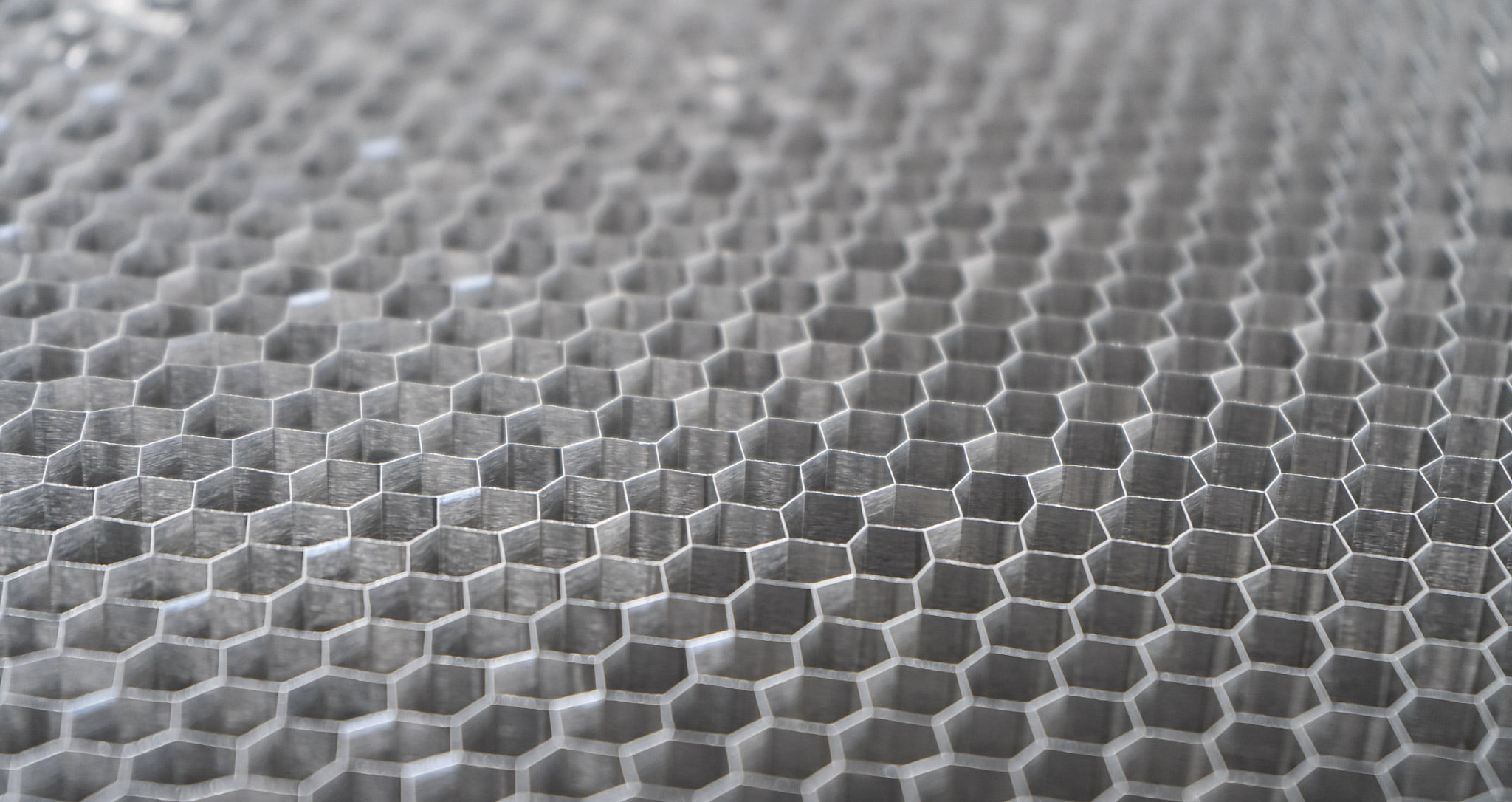

Honeycomb Bed

A durable aluminum table structure is inserted into the bed, maintaining a flat work surface. The honeycomb cells allow for a down draft table and also ducting smoke and debris into the bottom table chamber.

Laser Tool Kit

A kit with commonly used tools and consumables makes system maintenance fast and convenient. The kit includes a foam padded box with cutouts for each tool, making it easy to identify missing components.

ABOUT KCAM LASER SOFTWARE

KCAM® is a laser cutting and engraving software package developed by Kern’s in-house software development team. Through years of research and customer feedback, KCAM has developed into an industry-leading laser control software.

KCAM can be linked with popular design softwares such as CorelDRAW®, AutoCAD® and Adobe Illustrator®, allowing for hundreds of file types to be processed.A convenient user interface provides operators with complete control of the laser systems cutting and engraving parameters. Kern’s customers have access to the latest KCAM software upgrades from our website.

Whether you’re cutting thick acrylic or a thin delicate textile, be ensured that KCAM will provide you with the laser control required for quick and accurate results.

File Compatibility

A macro within CorelDRAW® automatically sends your artwork to KCAM® with the click of a single button. KCAM® is also capable of directly opening common file types such as .dxf, .pdf, G-CODE and many more.

Other popular CAD softwares such as AutoCAD LT®, Adobe Illustrator® and Solidworks® can be used to automatically load files into KCAM®.

Gives you Contol

Customized Pierce Settings. The dwell time, laser power, frequency, focus point and air flow can be set independently from your normal cut settings. This feature ensures metals are cut clean with minimal to no dross.

Air Control. Compressed shop air, oxygen or nitrogen can be hooked up to the laser system for optimal processing results on a variety of laserable materials.

Vector Path Speed Control. KCAM mimics a race car by slowing the cutting speed into sharp corners and accelerating out of them. The result is smooth, consistent cutting with the tap of your mouse.

Saves You Time

Cut Optimizer. Decrease your programming time by letting KCAM automatically determine the fastest cut order for your most complicated designs.

Time Estimator. Provide accurate pricing to your customers by knowing the amount of laser processing time before the product even makes it to the laser bed.

Tool Offset. A simple inside/outside offset can be set to compensate for the laser beam kerf. This results in precisely sized parts without modification of your original part drawings.

More KCAM Features

- Bottom-Up & Top-Down Engraving

- Vector Path Speed Control

- Soft Home Positioning

- Part Arraying

- Automation Pauses

- Vision Registration System

- Variable Extents Engraving

- Lead-In Speed Control

- Line Color Sorting

- PhotoGRAV Compatible

- Anti-Banding Engraving Mode

- History Log

- Nine Vector Cutting Colors

- Laser Printer Driver

- Time Estimator

- Power Density Control for Corners

- Multiple Modulation Modes

- System Usage Log

Request a Demo

Leasing & Tax Incentives

Kern has teamed up with Geneva Capital to bring you great new finance options. Financing makes it easy to get the equipment you need, while experiencing the benefits and tax savings of leasing.

President

Managing Partner

Information Technology Analyst