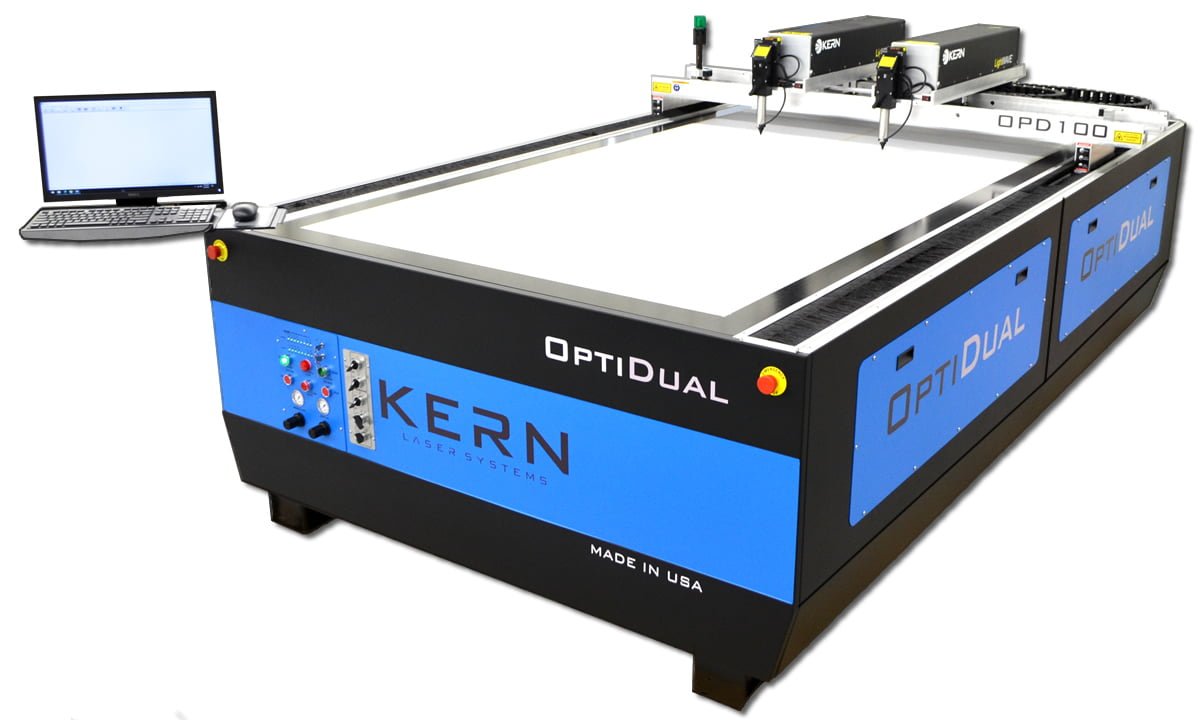

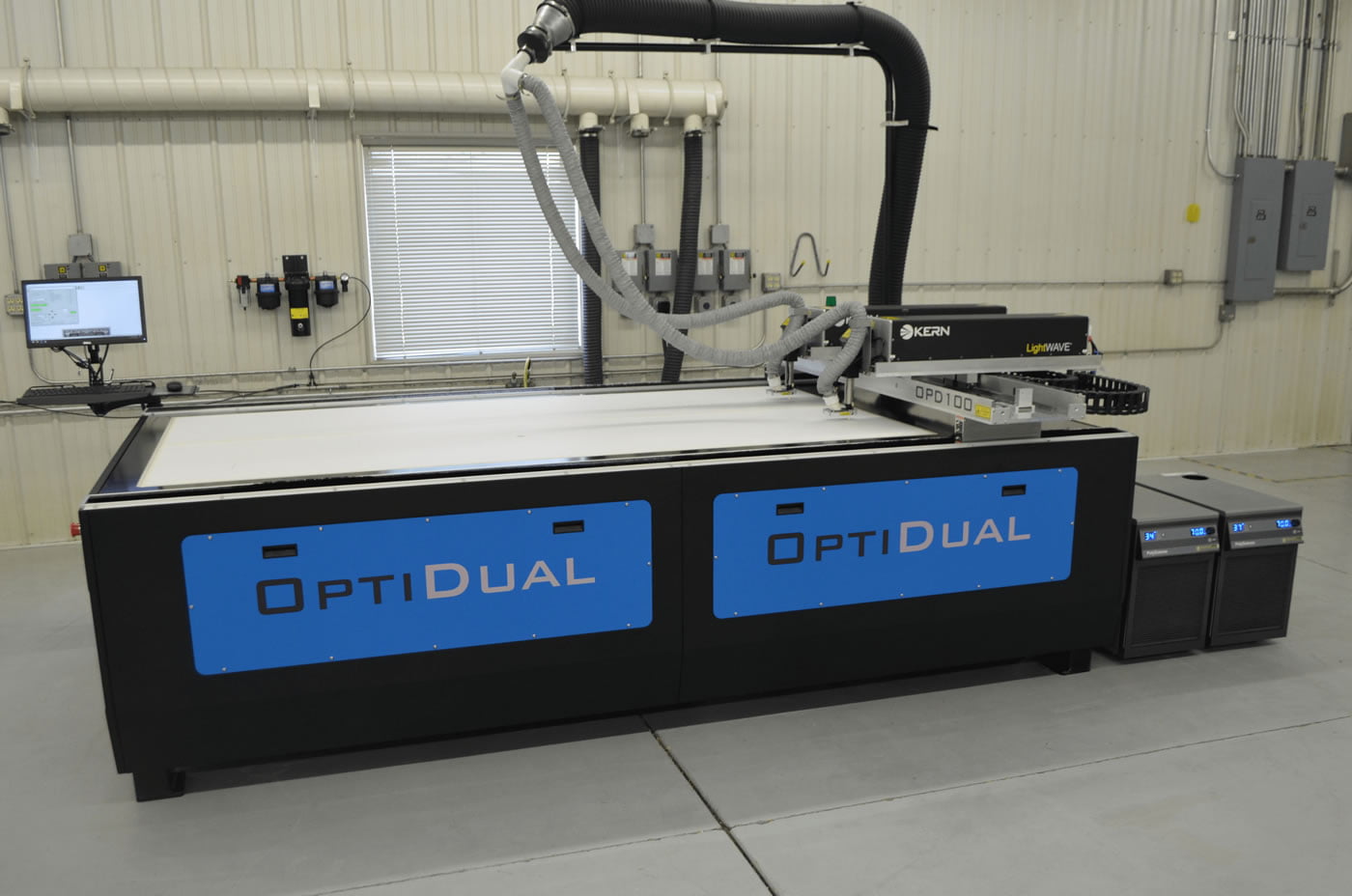

OptiDual - Dual Laser Cutting Machine

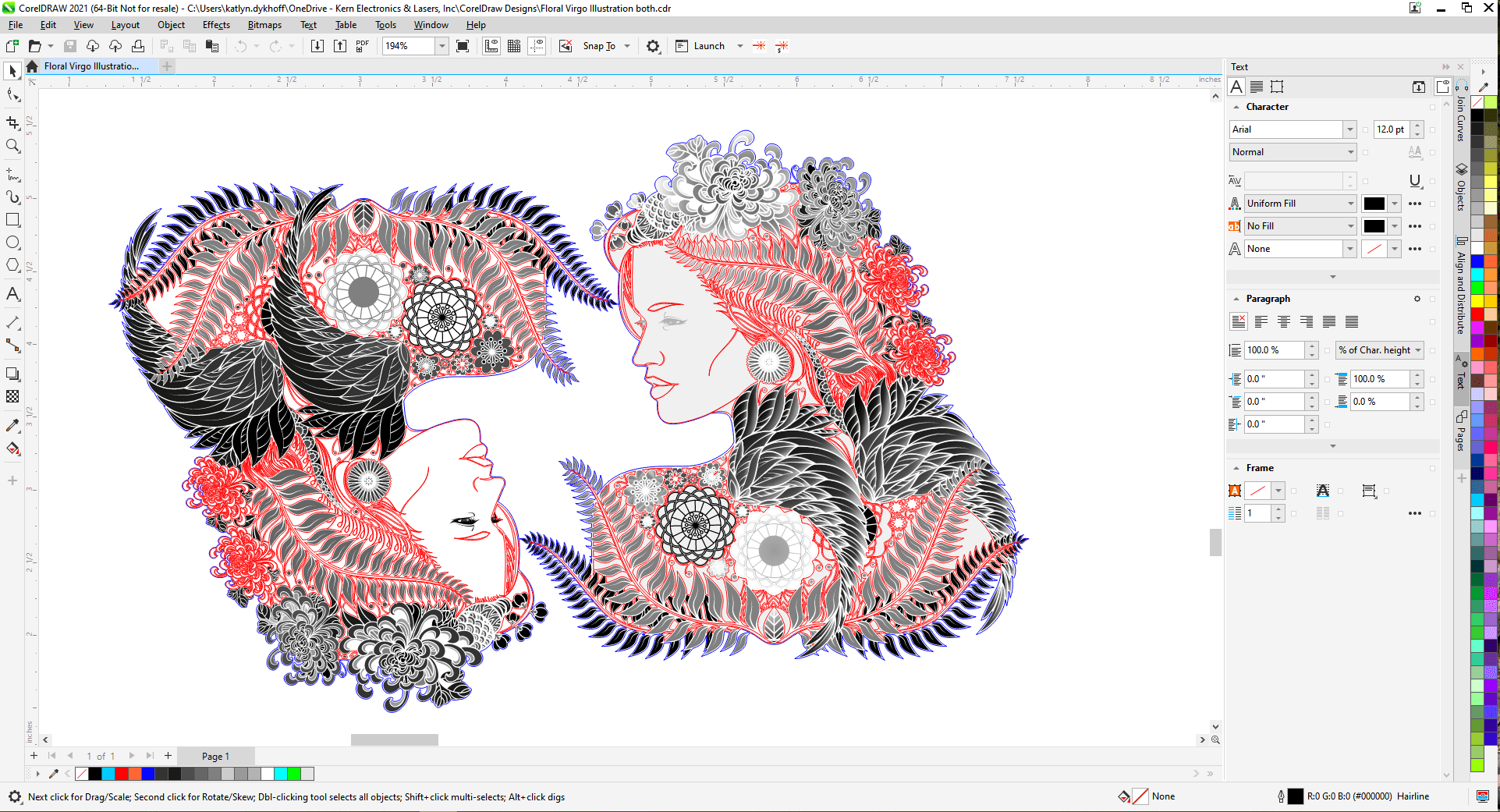

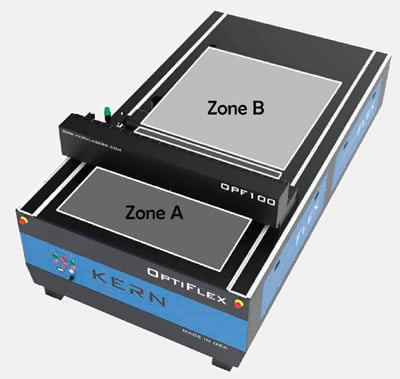

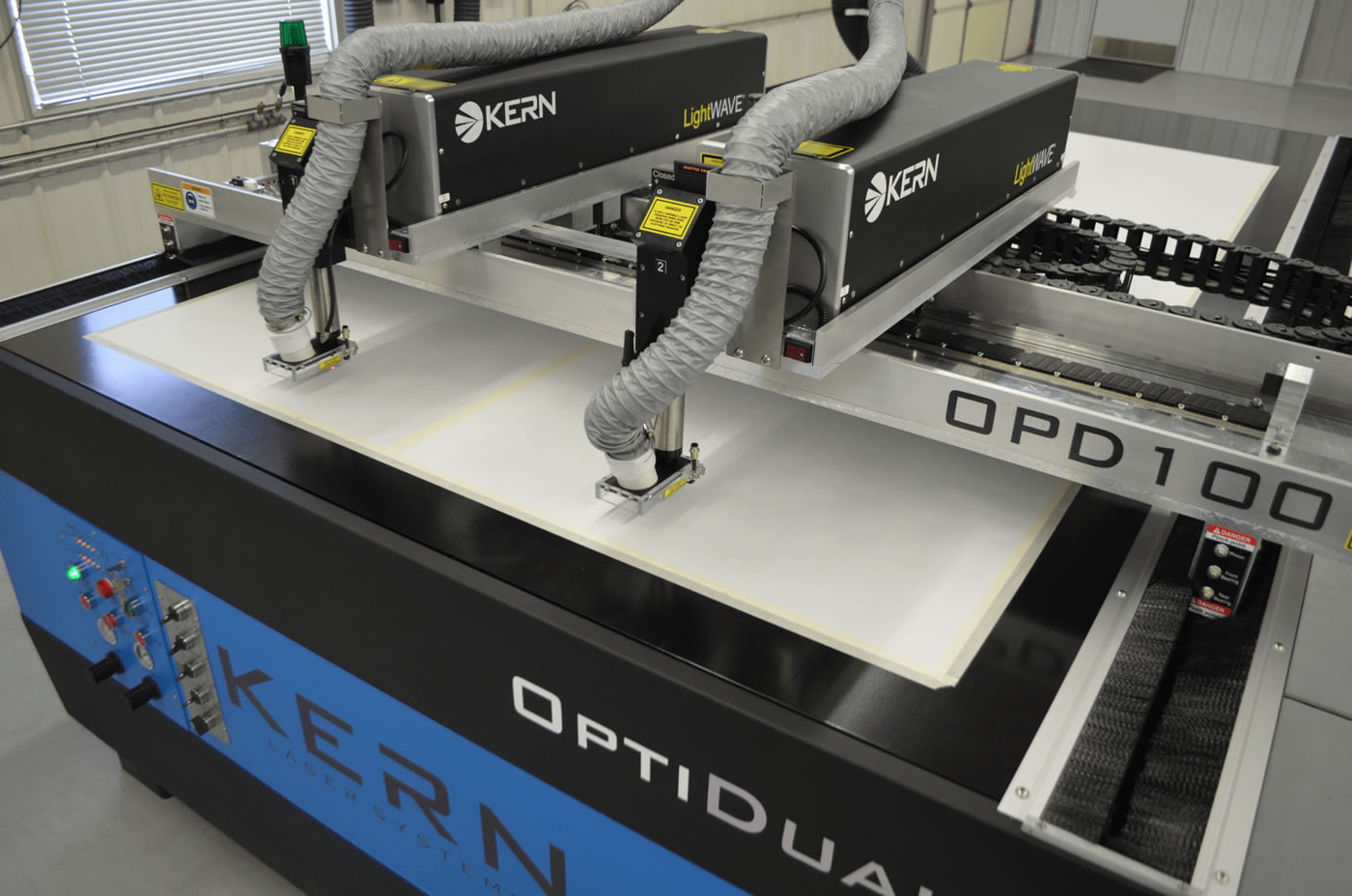

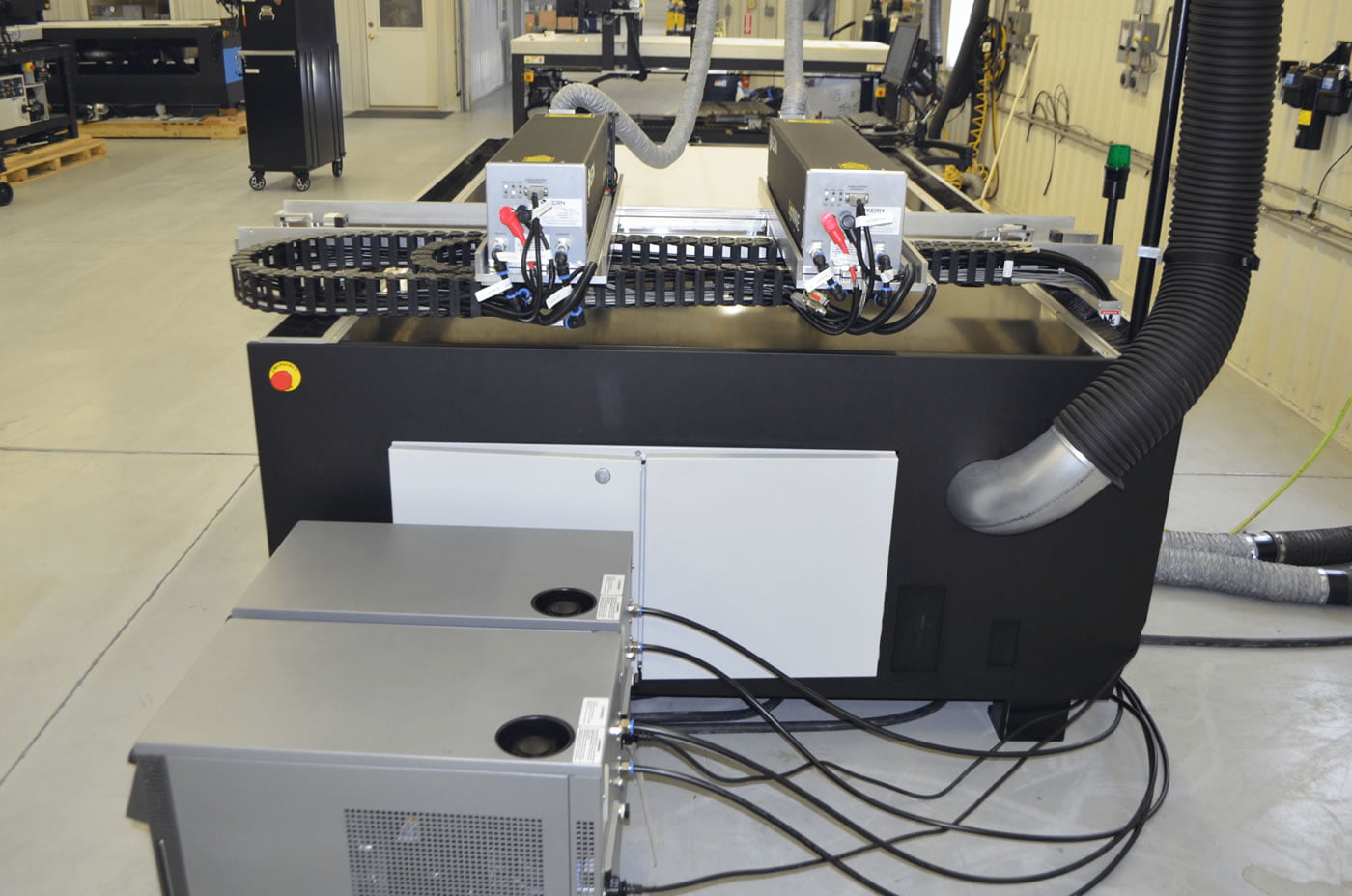

The OptiDual Laser System was specially designed for customers that require a laser system capable of high production cutting. The second laser is connected to the master laser by an adjustable bar. As the master laser is cutting a part, the second laser will be cutting the same part just inches away. Both lasers output power can be matched within the KCAM software. This ensures that the parts being produced are similar in size, accuracy and quality.

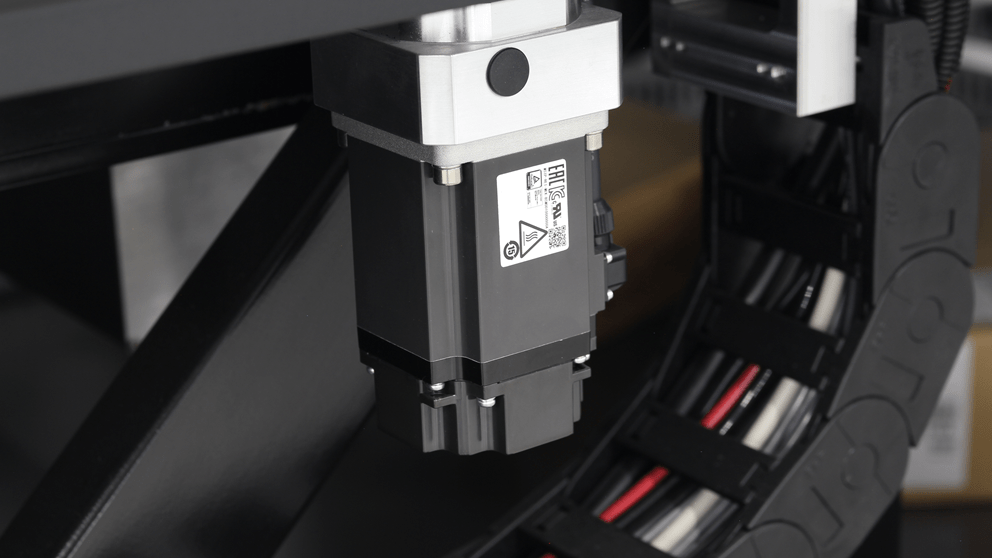

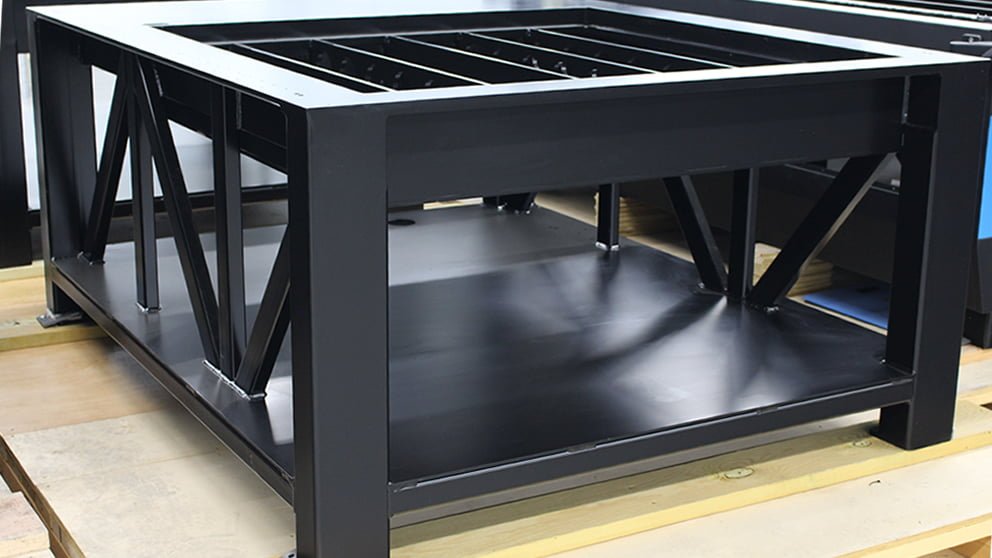

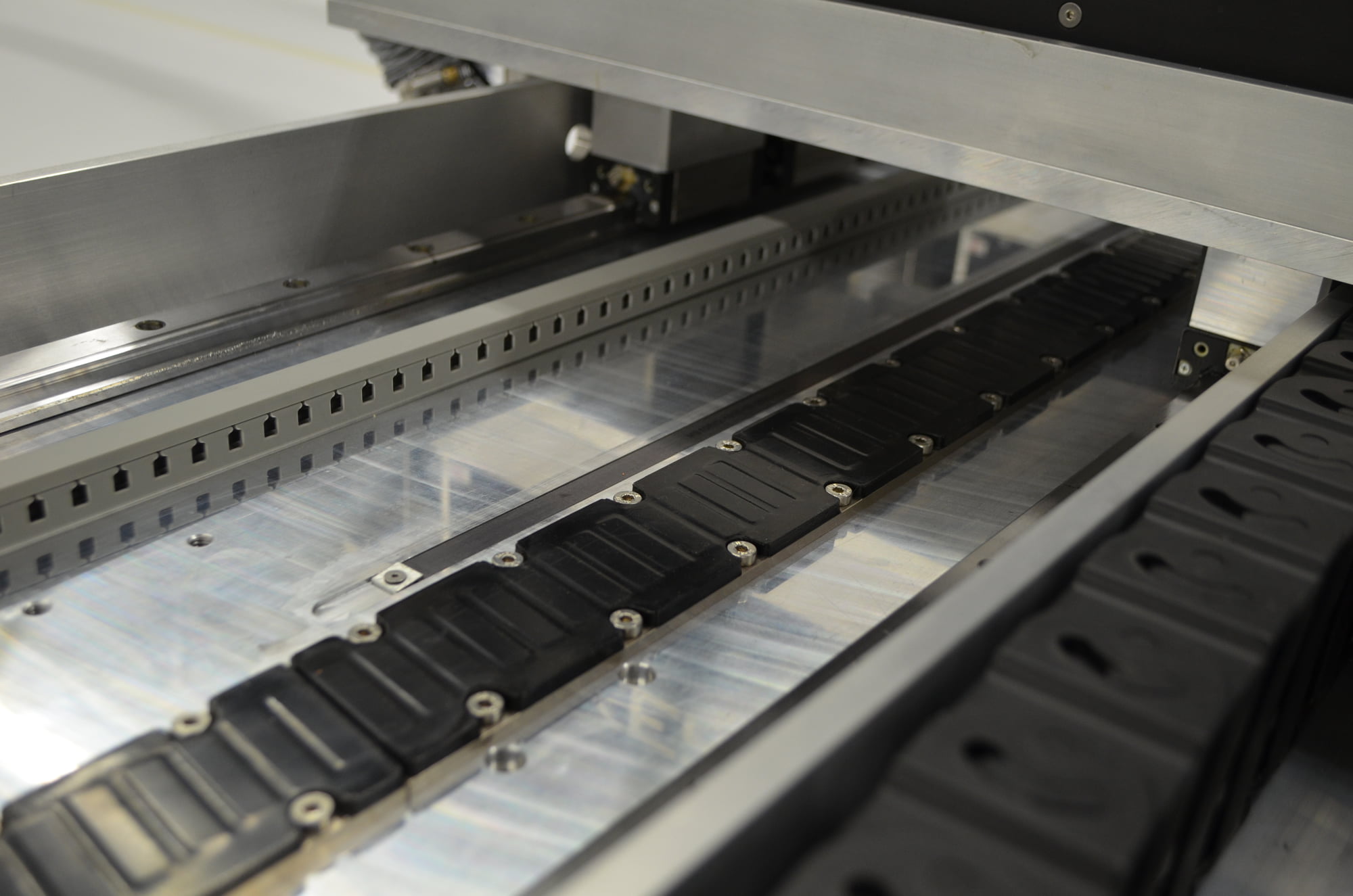

The OptiDual’s Y axis is powered by Kern’s HyperDual motion package. This includes high speed servo motors on each side of the table on a rack and pinion setup. The X axis has a linear motor and two precision rails resulting in fast, accurate and smooth cutting performance.

President

Managing Partner

Information Technology Analyst