To the layperson, the word “laser” can bring to mind some exciting, but perhaps not altogether comforting images out of popular culture: lightsabers and other sci-fi weapons from Star Wars, lasers used for security or intimidation in spy thrillers, laser-guided missiles, and submarines. And of course, lasers bring a more modest set of real risk factors associated with their improper use or malfunction—eye injuries, burns, and the like.

With this in mind, we’ll take some time in this article to dispel some common myths and misconceptions about lasers, specifically about laser-cutting machines like those we manufacture and sell.

Myth #1: Fiber lasers are better than CO2 lasers

Many people have the idea that a fiber laser is inherently better than a CO2 laser because fiber lasers are a newer technology, and they tend to be rated at higher wattages than CO2 lasers. However, the truth is more complex.

Fiber lasers are excellent for cutting through sheet metal, which is the purpose for which they are primarily marketed. For processing organic materials like acrylic, wood, or foam, CO2 lasers are the better option. We continue to sell more CO2 lasers than fiber lasers because of their flexibility for applications like these.

The high wattage ratings of fiber lasers can also mislead consumers into thinking they need a fiber laser for their application. This blog from Southern Fabricating notes that power efficiency is actually a better indicator of a laser’s appropriateness for a given purpose. This measure describes the amount of laser wattage focused in a small area. Lower-wattage lasers tend to be able to focus more of their power output into a smaller area, making for a faster cut in many cases.

You need to select the right laser for the job you want to do and the material you want to work with, and for many applications, a CO2 laser will be a better option than a fiber laser.

Myth #2: Laser cutting machines can cut anything

Although many people might think a machine that can slice through sheets of stainless steel can cut through pretty much anything, this is not the case.

There are materials that will cut very nicely and are great candidates.Then there are materials that last will cut but there are quality reasons (polycarbonate) or safety reasons (PVC, which emits harmful fumes when cut with a laser) not to cut it. However, we do have some applications where we cut very thin polycarbonate nicely. So sometimes you are just limited on the thickness you can cut. Last, there are material that just don’t cut nicely because they are too hard or will crack, like stone or glass. As noted in Myth #1, different types of lasers are better suited for cutting different materials.

There are materials that will cut very nicely and are great candidates.Then there are materials that last will cut but there are quality reasons (polycarbonate) or safety reasons (PVC, which emits harmful fumes when cut with a laser) not to cut it. However, we do have some applications where we cut very thin polycarbonate nicely. So sometimes you are just limited on the thickness you can cut. Last, there are material that just don’t cut nicely because they are too hard or will crack, like stone or glass. As noted in Myth #1, different types of lasers are better suited for cutting different materials.

Laser cutting machines are for precision, contact-free cutting and engraving applications. Each laser has limits as to the thickness of the material it can cut. Our 650-watt CO2 lasers can cut a quarter-inch of mild steel and .09” of stainless steel, for example, while our 3 kW fiber laser can cut .375” of mild steel and .188” of stainless steel.

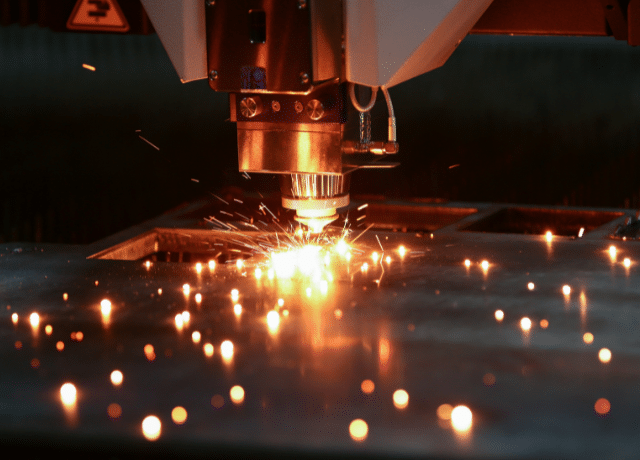

Myth #3: Laser cutting machines are dangerous

Consumers new to lasers often have concerns about the possibility of injury or of laser-induced fires. But, as noted in the CAMM Metals article cited above, laser cutting produces a relatively small, controlled amount of heat, very unlikely to spark a fire. Laser cutters do not char the edges of most cut materials (wood being a slight exception), and for some materials, they naturally seal the cut edges.

Laser-cutting machines also tend to be designed to minimize potential issues. That is the case with our designs: All of our laser systems are equipped with thoughtfully integrated and appropriate safety features. The FiberCELL and LaserCELL systems, which are two of our most powerful products, geared toward cutting sheet metal, both come built into Class 2 safety enclosures, allowing them to be installed safely in relatively high-traffic areas.

But open bed designs can be safe as well, as long as the user wears properly rated safety glasses. We don’t cut safety corners with any of our machines: All of our laser systems are CDRH laser machinery-compliant.

Of course, one of the most important safety elements for working with any professional machinery is the knowledge and experience of the user, and we sell some of that experience with each of our lasers, in the form of a standard two-day training program at our factory.

Myth #4: Laser cutters are all basically the same

Even before you consider our laser systems against the competition, a cursory glance at our product portfolio shows this to be a myth: We offer a variety of integrated laser systems with varying output powers, features, specifications, and configurations to suit many laser cutting and engraving applications. Most of our CO2 laser systems can be equipped with lasers of any of the following wattages: 100W, 150W, 200W, 300W, 500W, and 650W. Our FiberCELL fiber laser can be equipped with lasers between 1 kW and 3 kW.

Of course, we also think we stand out in comparison to our competitors. Our machines are built in the USA to rigorous quality standards and we work hard to eliminate confusion and make troubleshooting a breeze. With foreign-built laser products, this is not always the case, parts may not be clearly labeled, parts and build may be subject to looser tolerances, and if you run into a problem, even very well-meaning customer service might fail to solve a problem across a language barrier.

Myth #5: Laser cutting machines require a ton of maintenance time

False! Maintenance on our laser systems can be completed in as little as 10 minutes per week. The laser system manual will highlight a daily, weekly, and monthly schedule. Common maintenance procedures include replacing chiller fluids, greasing bearings, oiling rails, cleaning optics, and cleaning filters.

We also take pains to consider and create features for our systems that will aid in or eliminate regular maintenance. For example, the FiberCELL comes with a slat-cutting table in the bed of the system, as well as a CAD file for cutting replacement slats.