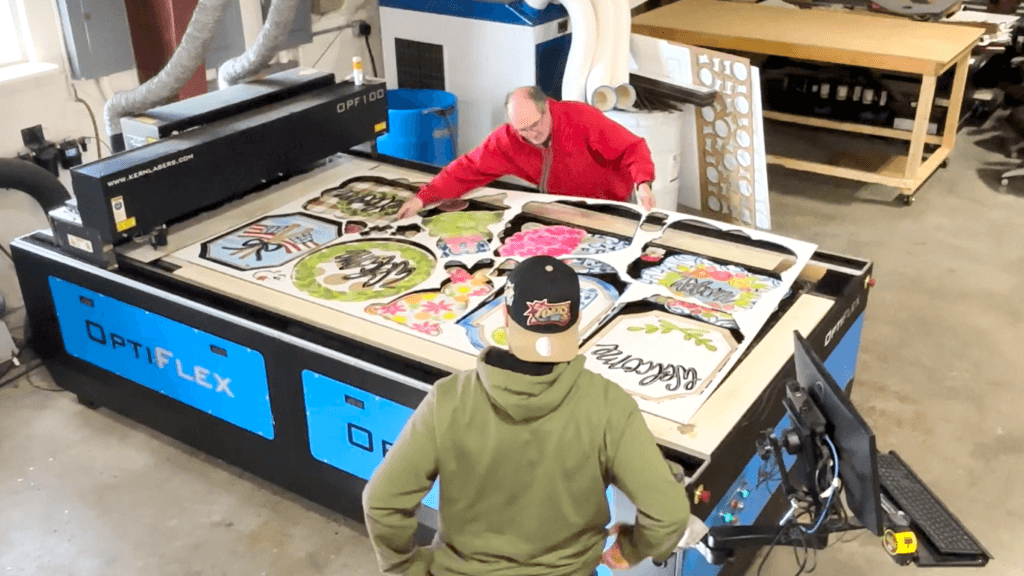

When you’re in the laser business, you get a lot of questions. Below, we’ve answered 10 of our most frequently asked questions.

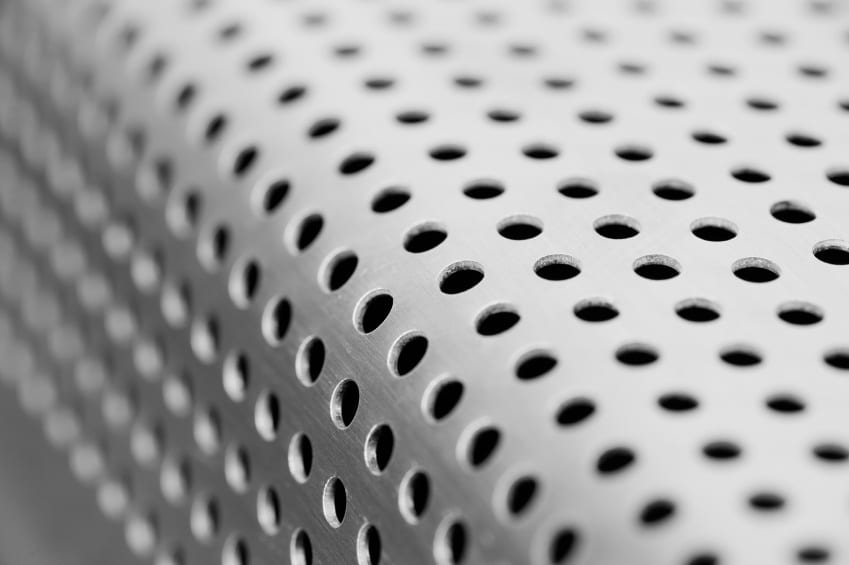

CAN A CO2 LASER CUT METAL?

Yes. A properly outfitted CO2 laser can cut metal. We’ve developed a metal cutting option, which allows CO2 lasers to cut metals with relative ease. We’ve been doing it for years.

HOW THICK OF MATERIAL CAN I CUT?

It depends. More specifically, it depends on three primary variables:

- Laser wattage

- Material type

- Material thickness

If you have a particular metal you’d like to discuss, you can always contact us to discuss the specifics of your material. We will help you determine how or if you’re able to use a CO2 laser cutter to process your desired thickness.

Another option is to send a piece of your material to us and we will cut it into a shape and send it back to you. Then, you can see the edge quality and cut quality for yourself to determine if it meets your standards. Click here if you’re interested in having us test your material on a Kern Laser System.

HOW FAST CAN WE CUT THE MATERIAL?

It depends. Laser cutting speeds depend on three primary variables:

- Laser wattage

- Material type

- Material thickness

For example, let’s look at how wattage impacts CO2 laser cutting speeds.

If you’re cutting ⅛” acrylic plastic on a 150W laser, it’s going to cut 3-4 inches per second. Now, if you take that same material and cut it on a 400W laser, it’s going to cut at about 6-7 inches per second.

HOW FAST CAN I ENGRAVE?

Engraving speeds on Kern Laser systems are anywhere from 100 inches per second to 150 inches per second. These speeds are for surface engraving, which typically uses a lower power to mark the surface of a material.

3D engraving, which involves putting depth into a material, anywhere from 3/16” to 1/4″, has speeds that vary from 20 inches per second to 45 inches per second. 3D engraving speeds depend on the intricacy of the pattern.

HOW DOES THE LASER CREATE THE DEPTH OR 3D EFFECT IN THE WOOD?

The laser engraves at varying depths to create a 3D effect using grayscale. Our KCAM software is able to read 256 different shades of grey, and those shades tell the laser what depth to engrave to.

For example, if you drew a three-inch square and made half of it black and the other half light gray, the laser could engrave it at around 30-40 inches per second. The black part of the square would engrave much deeper into the wood than the light gray would.

WHAT IS THE MAIN SAFETY CONCERN WHEN OPERATING THE LASER SYSTEM?

Overall, operating a laser system is safe. Like all CNC equipment, when operating an open bed (Class 4) laser system eye protection is required. Always rely on your company’s LSO (laser safety officer) to determine the correct laser safety glasses. And remember, enclosed (Class 2) laser systems — like our FiberCELL and LaserCELL — do not require safety glasses.

IS THERE A RADIATION HAZARD INVOLVED WITH YOUR LASER SYSTEMS?

No. This is an infrared radiant energy that is produced when operating the laser. It’s the same energy that is used in commercial and residential appliances like microwaves. It is a well-tested, very safe way of creating heat.

WHERE ARE YOUR SYSTEMS BUILT?

We design and build all of our systems in our factory here in Wadena, Minnesota. It’s been this way since 1982. Everything in the system is American-made.

WHAT OPTIONS CAN BE ADDED TO KERN LASER SYSTEMS?

Pipe rotary, k-vision, metal cutting, Z12 monument package, advanced safety package, fume scrubbers and PhotoGrav software.

To discuss available options, please contact us.

DO YOU OFFER TECH SUPPORT?

Yes. We have a technical support team capable of helping with any issue you have. When you call Kern Laser Systems during business hours, you will be greeted by a live receptionist. We pride ourselves on providing excellent customer service. Please check out our testimonials to hear from our customers about their experiences with tech support.