Kern offers many optional additions to our standard laser systems to allow users increased flexibility, both in terms of the materials they process on the laser and the ways those materials are processed. For this post, we’ll put the spotlight on one of these add-on features: the rotary attachment for pipe and tube cutting.

Most laser cutting and engraving systems are optimized for cutting sheets of material, and laser systems that can cut pipes are built specifically for that purpose. This kind of laser is intended for users who are really only cutting metal pipes, and it doesn’t do much else. Our rotary attachment, however, is simultaneously a more entry-level option to get into pipe cutting and a more versatile tool that allows for a wider variety of applications than the typical pipe-cutting laser.

One of our lasers equipped with the rotary attachment is a good option for customers with space limitations since this is a much more compact set-up than a heavy-duty, devoted pipe-cutting laser. The flexibility of our machines also means the user can quickly switch to pipe cutting with the rotary attachment, and then switch back to processing standard sheets of material.

The rotary attachment can be added to any Kern model except the EcoFlex. The attachment works by turning over what would regularly be the y-axis to a rotary motor attached to a lathe chuck. The chuck spins the pipe, and the laser, moving along the x-axis, cuts along the pipe’s length.

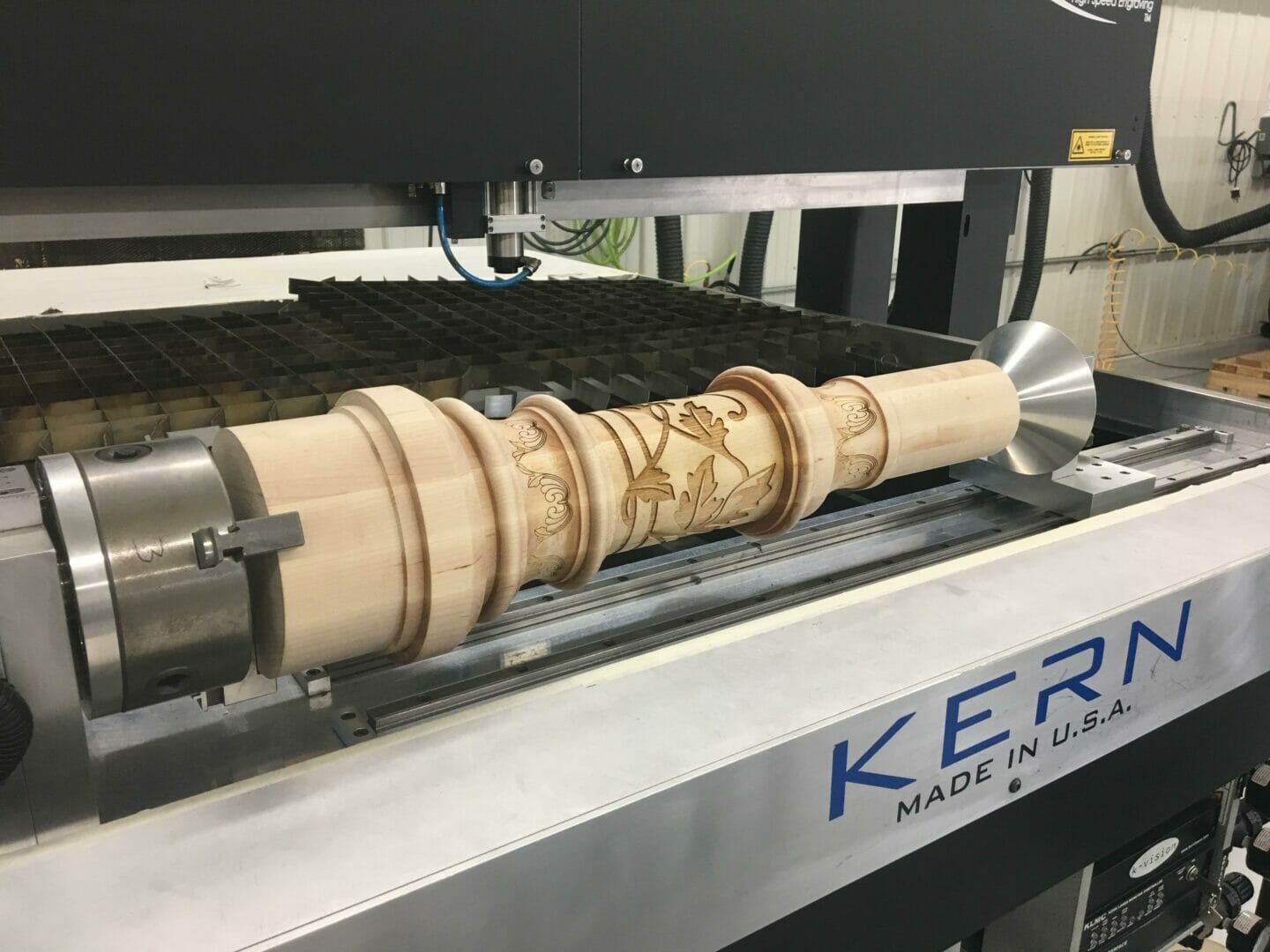

We offer two styles of rotary attachments. There is the chuck rotary, where the pipe or tube to cut is gripped firmly and turned by a lathe chuck. And then there is the roller wheel style rotary, where the workpiece is held onto wheels by the force of gravity; this allows for full-width engraving of the workpiece. The wheel roller style is more aimed at artistic applications.

We also offer a beam dump feature that can be incorporated with the chuck rotary. The beam dump is useful when cutting materials like clear acrylic or any tube that is transparent. When you cut through the top of the acrylic tube, the beam typically at least marks the opposite side of the tube, or it may cut all the way through if too much power is used. For many applications, this cut or mark on the opposite side of the tube is not acceptable and would be seen as a cosmetic flaw in the part. To eliminate this problem a metal pipe with slots cut into it is positioned down the center of the acrylic tube This metal pipe serves a double purpose: Not only does it protect the bottom(opposite) side of the tube from being marked by the laser beam, it also can act as a fume removal system. A vacuum blower is connected to one end of the metal pipe pulling the fumes created in the cutting process into the slots on the metal pipe. The fumes are then ducted safely away from the final product. Lingering fumes can cause blemishes or a cloudy appearance on materials like clear acrylic so it is best to have them removed as quickly as possible.

Uses for the Rotary Attachment

The rotary attachment allows our customers to cut pipes and tubes for purposes ranging from the industrial to the creative.

Many of our customers are using the rotary attachment to cut slits or holes. For example, customers creating exhaust pipes use the laser with the rotary attachment to cut a shape out of the pipe that allows exhaust to escape.

Other customers use the rotary attachment to cut specifically shaped joints, for example, a “Y” shape that joins two lengths of pipe together. There is software available that can easily generate the cutting file geometry needed for cutting these Y joints.

Our KCAM software also contributes to the ease of using the rotary attachment to break down lengths of pipe for parts manufacturing: If you can simply measure the diameter of the pipe to be cut, KCAM can do the math to determine the circumference, making it easy to cut a section off the end of the pipe or tube. All you have to do is draw a straight line in CorelDraw equal to the diameter of the pipe.

The rotary attachment can also be useful for creative and artistic applications, a realm unavailable with many other kinds of pipe-cutting laser systems. One customer, for example, is using the rotary attachment to make walking sticks for the scout troop they are involved with; as the scouts earn badges, they receive engraved images of the badges on their walking sticks. Another example is a customer using the rotary attachment to make engraved rolling pins.

The rotary attachment is also good for cutting plastic and acrylic. These are good materials for making parts for toys or games for kids. For plastic or acrylic tube engraving, Kern’s laser systems are actually one of the few options on the market.