For some consumers, the type of laser they should buy is clear. A fiber laser is usually going to be the obvious choice for cutting large amounts of heavy sheet metal, for example. But for consumers who want to process a variety of materials, or who want the option to widen the scope of their work in the future without needing to buy a new laser, the question is more complex. They want a universal or multi-function laser, a jack-of-all-trades that gives them the widest set of possibilities while maintaining acceptable output quality across the board.

The perfect “do-it-all” laser system might not exist, but some lasers out there can get you pretty close, and as a manufacturer of some of the most versatile laser cutting and engraving machines on the market, we can help consumers determine some of the things to look for in a multi-purpose laser system. In this post, we’ll offer some guidance on the features that contribute most to a laser’s versatility.

The Software

Most lasers can do multiple things, but not every laser can do many things well. Several features are important to suiting a laser system to multiple functions, but one of the biggest is the software used to control the laser. Some companies use off-the-rack software solutions, while others (us included) use proprietary software. Regardless, your laser cutting hardware isn’t likely to turn out a consistent, high-quality product if the software brain driving it doesn’t offer enough user control or precision.

Most lasers can do multiple things, but not every laser can do many things well. Several features are important to suiting a laser system to multiple functions, but one of the biggest is the software used to control the laser. Some companies use off-the-rack software solutions, while others (us included) use proprietary software. Regardless, your laser cutting hardware isn’t likely to turn out a consistent, high-quality product if the software brain driving it doesn’t offer enough user control or precision.

The biggest contributor to the across-the-board quality of our lasers’ output is our KCAM software. KCAM offers the user control over a tremendous number of cutting and engraving parameters, including the kinds of things you don’t know you need until you need them. For example, it can adjust for tiny discrepancies between the cutting file and the actual placement of the workpiece on the laser table, ensuring the final product comes out exactly as intended.

CO2 and Versatility

If your work demands a laser cutting machine that can deal with several different materials and purposes, you are most likely looking for a CO2 laser. Consumers new to laser cutting often expect they want a fiber laser because fiber lasers are capable of much greater output wattage than CO2 lasers, and people tend to equate more of anything with better. In the world of laser cutting and engraving machines, this assumption is especially inaccurate. Fiber lasers are essentially just sheet metal cutting machines. If you need real versatility out of your laser, you need a CO2 laser. A relatively high-power CO2 laser can cut plastics, foams, rubber, wood, fabrics, and many other materials, and in some cases, these lasers can even cut through sheet metal. Granted, if you need to cut sheet metal above a certain thickness, you will still need to use a fiber laser to do so. But if your needs include modest sheet metal processing as well as working with other material types, CO2 is the way to meet all of those needs in one machine.

Size

The size of your machine’s laser table is also an important component of versatility. On a small laser table, it is common for users to have to break down their sheets of material before loading them onto the table, often by cutting them into quarters. This requires using another tool, like a water jet, to cut the material down to size before processing it with the laser. This extra step can usually be avoided on a Kern machine because we offer larger table sizes than many of our competitors. Our most popular products tend to be larger lasers on mid-size tables, for example, a 4’ x 8’ table with a 150 or 500-watt laser.

A larger table also allows you to make larger final products. Many customers switching to our lasers from brands with smaller tables have told us stories of turning down work due to the size of their machine.

Options and Customization

Our optional features can certainly take our systems’ versatility to the next level. We offer three major additions to our standard configuration: the metal cutting package, the K-Vision camera, and the rotary attachment. Customers can choose to add all three or any combination of them.

Metal Cutting

We frequently meet people at trade shows who are surprised by the ability of our CO2 laser systems to cut sheet metal. They are surprised they can cut everything they need to cut with a single CO2 laser of a high enough wattage. About 80% of our sales have our metal cutting option installed, and that’s often the difference that pushes customers to our product.

K-Vision Camera

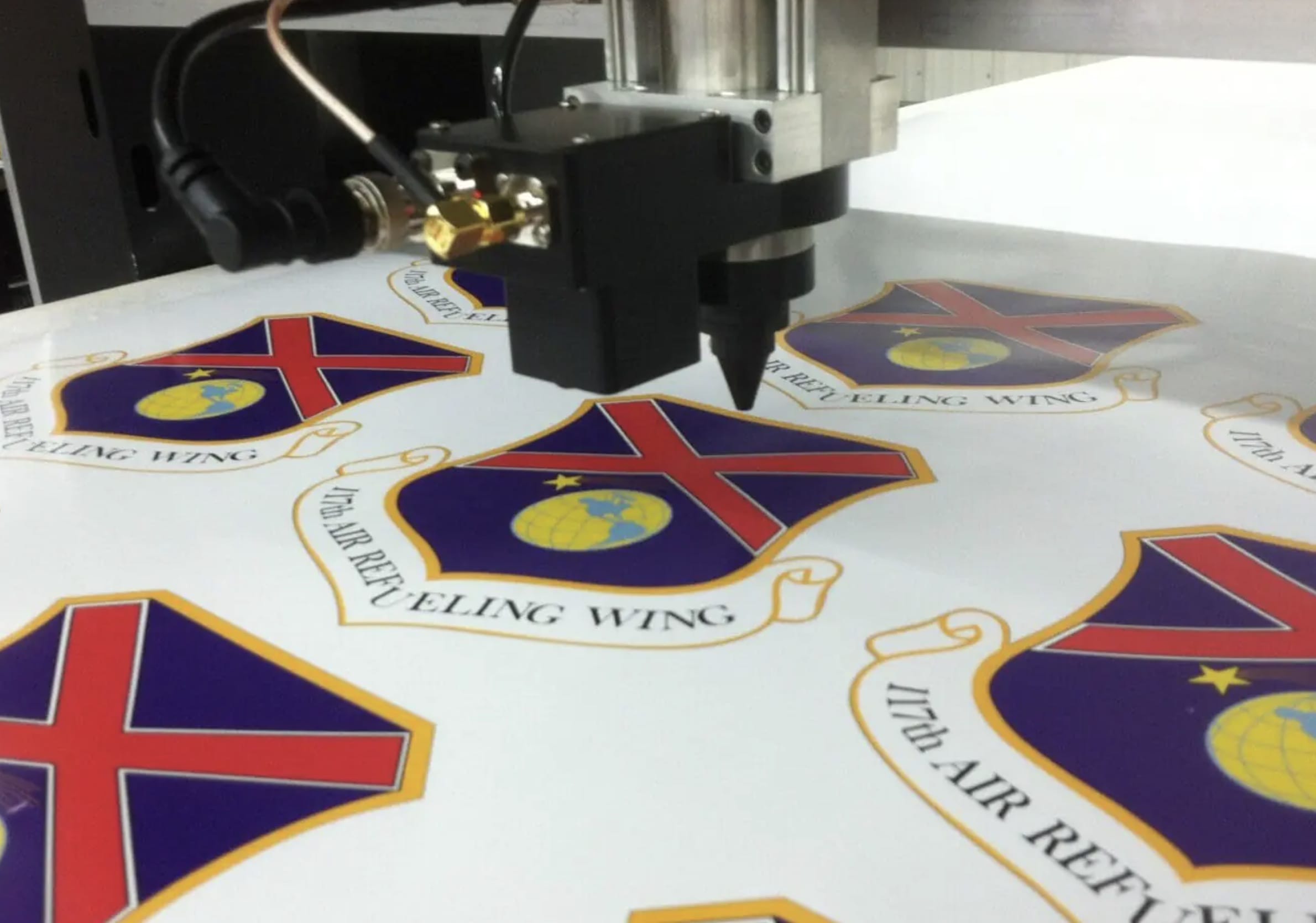

Our K-Vision Camera is useful when cutting any kind of pre-printed material, where the laser system needs to be able to “see” and cut around a printed design. K-Vision measures distances between registration marks on the material and accounts for any distortion or rotation to ensure a uniform cut product.

Rotary Attachment

The pipe and tube rotary attachment is used for cutting pipes and other cylindrical pieces, like bars and plastic tubes. We offer both a chuck rotary and a wheel rotary to serve different pipe- and tube-processing purposes. The wheel rotary is great for engraving the outside surface of a piece. The chuck rotary is commonly used for making exhausts and pipe joints.

All three of these optional add-ons can add versatility to your laser cutting machine, and if you’re considering multiple laser manufacturers, you can ask others if they offer any similar functionality on their machines. But if you’re still uncertain whether there’s a laser cutter out there for your purpose, we are also able to add certain customizations to our machines on a case-by-case basis. Contact us to discuss any material or application you need a laser to complete, and we will be happy to discuss options and possibilities with you.