When’s the last time you had to shut down to wait for laser repair or maintenance? Whether you’re operating a laser out of a job shop, small business or for a larger production outfit, downtime due to equipment failure is never a good thing.

Nowadays, profit margins are tighter than ever, and CO2 laser repair services aren’t always easy to access.

By paying attention to the needs of your laser system and providing it with appropriate, ongoing maintenance, you can extend the life of your laser system, prevent costly downtime and keep the laser’s processing capabilities at peak performance.

RECEIVE PROPER TRAINING

From one laser to another, you’re going to find a lot of similarities, but no two systems are exactly the same. Understanding the specifications and quirks of your system will help you to provide it with proper maintenance and more effectively troubleshoot issues when they arise.

Choosing a laser system from a company that provides training is a great way to ensure you know the ins and outs of its maintenance requirements. Additionally, always review the operator’s manual of a new laser system. It will provide maintenance directions and usually include a maintenance schedule as well.

KEEP THE SYSTEM CLEAN

Across the board, keeping your laser system and work area clean is a recipe for success. Some materials create a high volume of dust and debris during processing. Failure to clear away dust and debris can get in the way of laser processing and lead to end products with diminished quality. It is always recommended to keep your work area clean and debris-free.

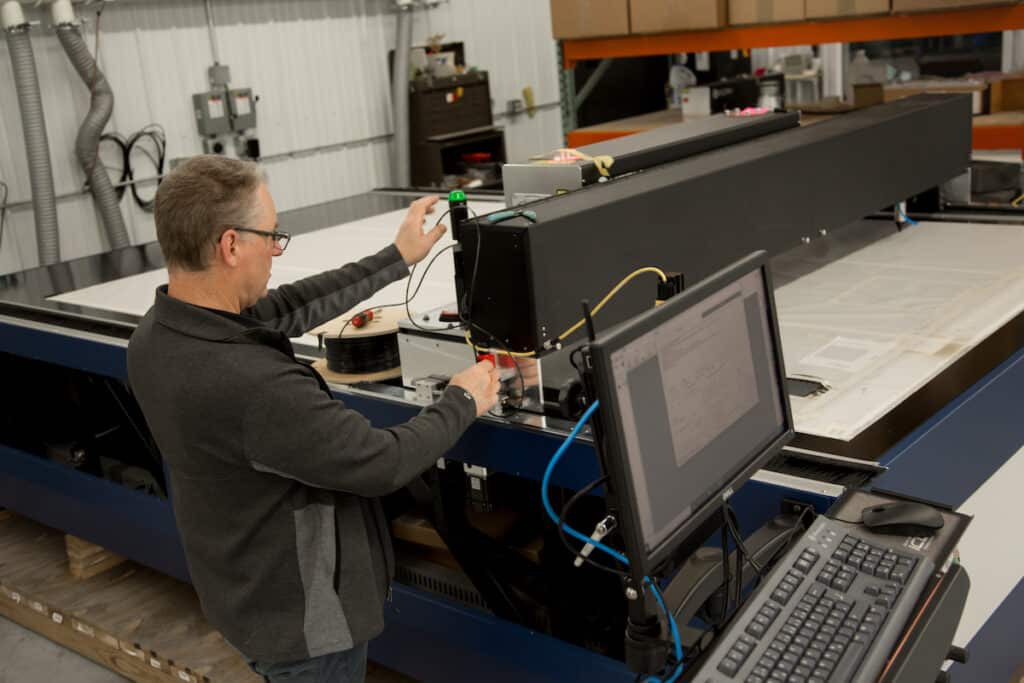

INVEST IN A LASER DESIGNED FOR EASE OF MAINTENANCE

Any way you cut it, a laser system is a big investment. It’s true whether you’re upgrading from your current laser system to a bigger, faster, higher wattage system or you’re considering making the move from a more manual process to laser processing.

With a big investment, it pays to do your due diligence to not only keep your machine running properly, but to make sure that whatever product you choose is one that makes maintenance accessible.

As we’ve established, all laser systems require maintenance, but it’s worth noting how much maintenance a system requires and how difficult it is to provide that maintenance as it will differ from system to system.

In some instances, you’ll find systems designed for easy maintenance. Basically the nooks and crannies you need to get into are easily accessible and the same goes for wear parts. Those systems are going to save you time and frustration over the lifetime of ownership.

At the end of the day, a well-maintained laser system is going to provide consistent performance over long stretches of time. In order to get the most out of your laser system, give it the maintenance it needs and deserves. By receiving proper training, keeping the system clean and investing in a laser that’s designed for ease of maintenance, you’ll be well on your way to reducing downtime and growing your profit margins.