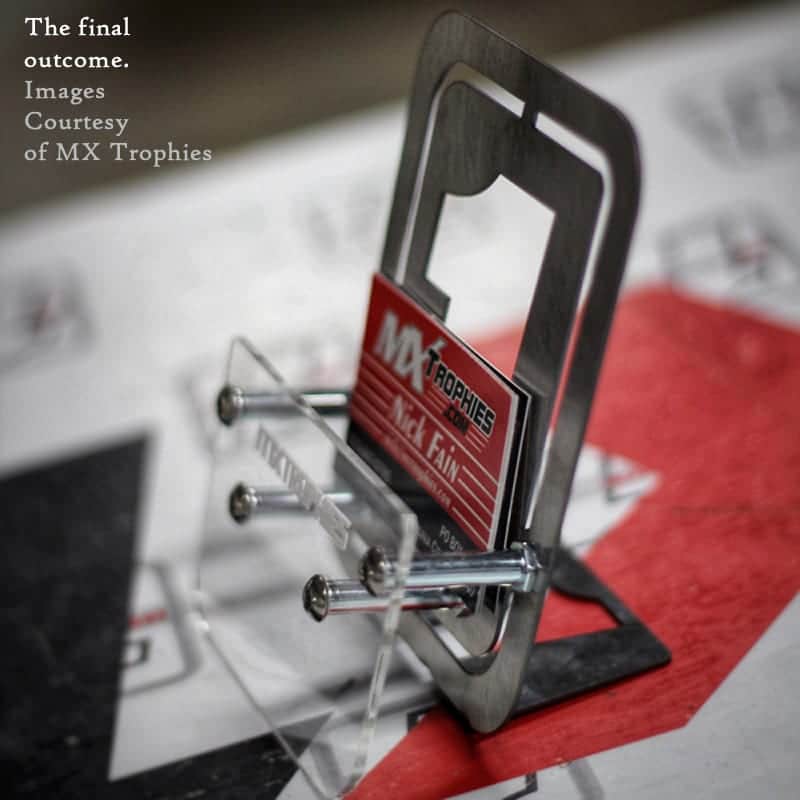

A Custom Trophy Build

Do you have a need to process wood, plastics, metals and foams with one machine? Kern offers this versatility for a wide spectrum of customers and ultimately their imagination is their only limitation.

MX Trophies, a Kern customer, uses their creative skills daily to produce custom awards, plates and medals. The ability to personalize individual products to each event allows them to stand out from their competition. Here is how MX Trophies uses a combination of stainless steel and acrylic to create a custom business card holder.

MATERIALS NEEDED:

- .050″ stainless steel

- .125″ cast acrylic

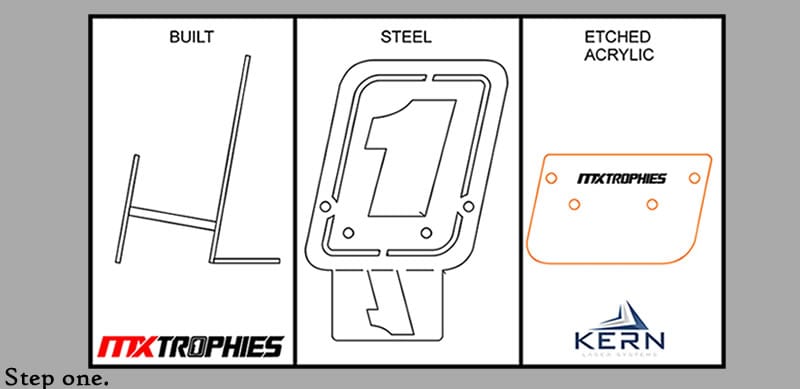

Step 1: Create and Export File

Within CorelDRAW, multiple cut-line colors are used to assign settings to the different substrates being cut. The image or text is added to areas that need to be engraved. Once the file is complete a simple export tool sends the creation to the laser.

Step 2: Set Parameters

KCAM software is used to set the laser power, speed, and other common settings.

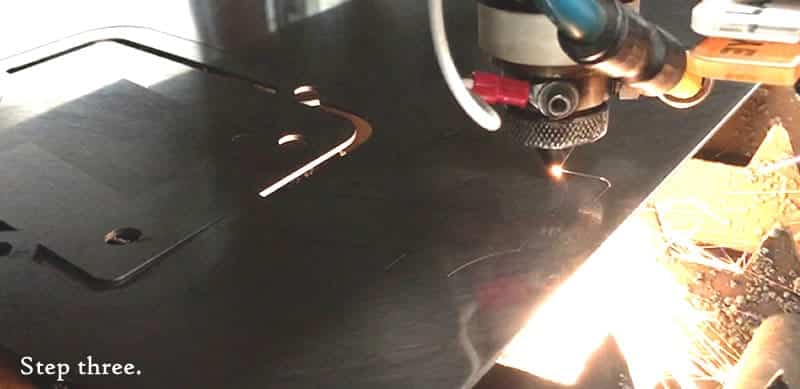

Step 3: Cut Stainless Steel

Load the steel sheet and adjust the focal height of the metal cutting assembly. Enable the cut-line colors assigned for the stainless and click Start.

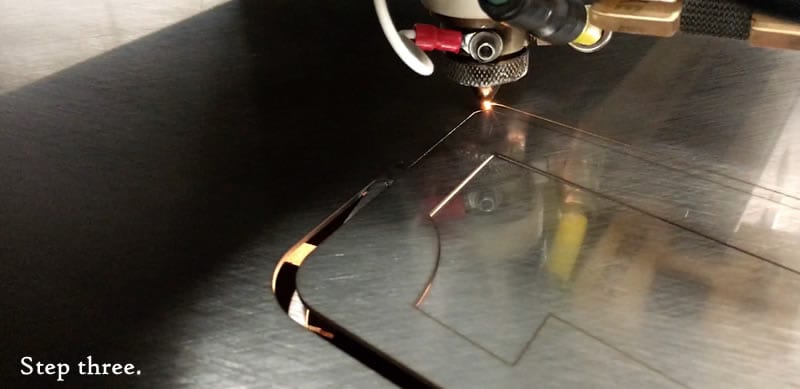

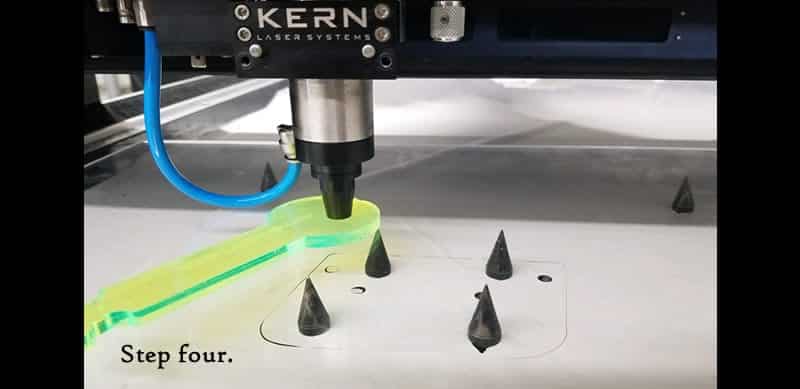

Step 4: Cut and Engrave Acrylic

Install the acrylic processing head and honeycomb bed. Add standoffs to reduce flashbacks on the back side of the acrylic being cut. Load the acrylic sheet. Enable the cut-lines color assigned to the acrylic as well as the engraving option, and click Start.

Step 5: Assemble

Suggested Parameters (250 Watt Laser):

.050” Stainless Steel

Speed: .75”/sec

Power: 90%

Frequency: 1000Hz

Assist Gas: Oxygen (100 psi)

Acrylic Etching

Speed: 50”/sec

Power: 20%

DPI: 300

Air Pressure: 12psi

Acrylic Cutting

Speed: .5”/sec

Power: 40%

Air Pressure: 5 psi

Watch the Build Process: