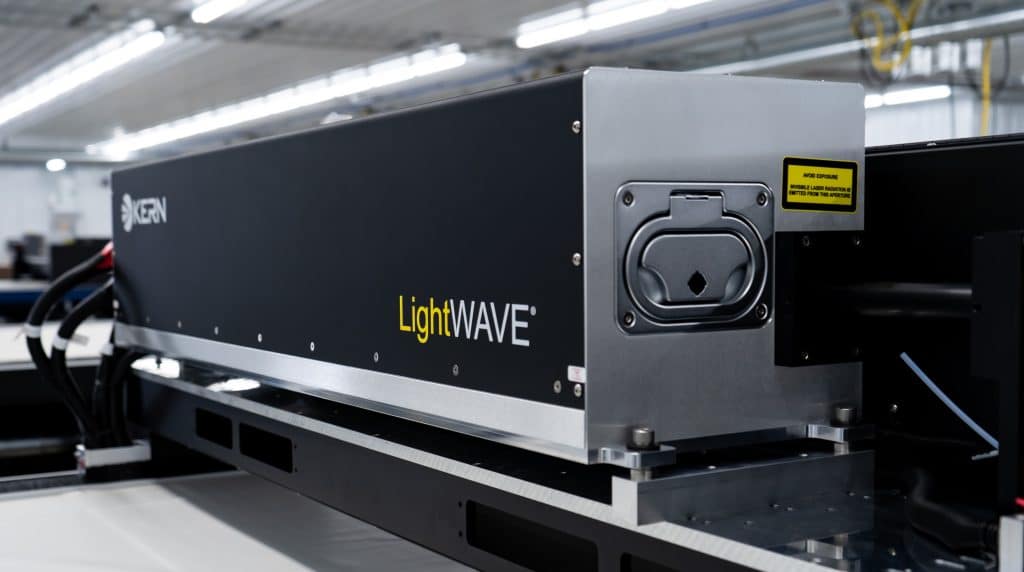

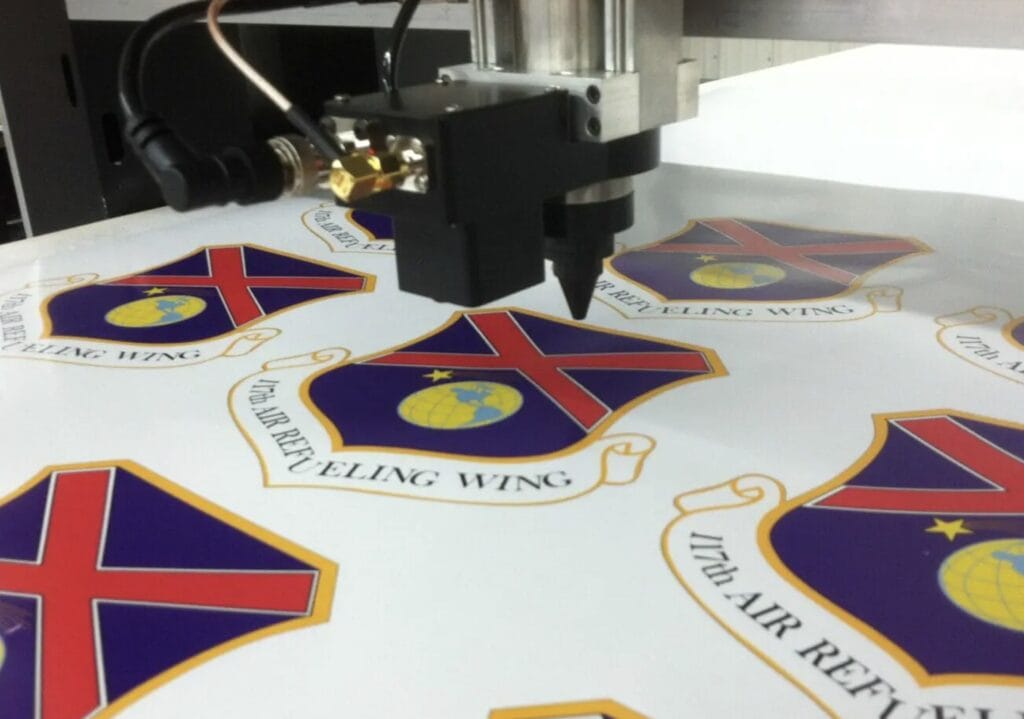

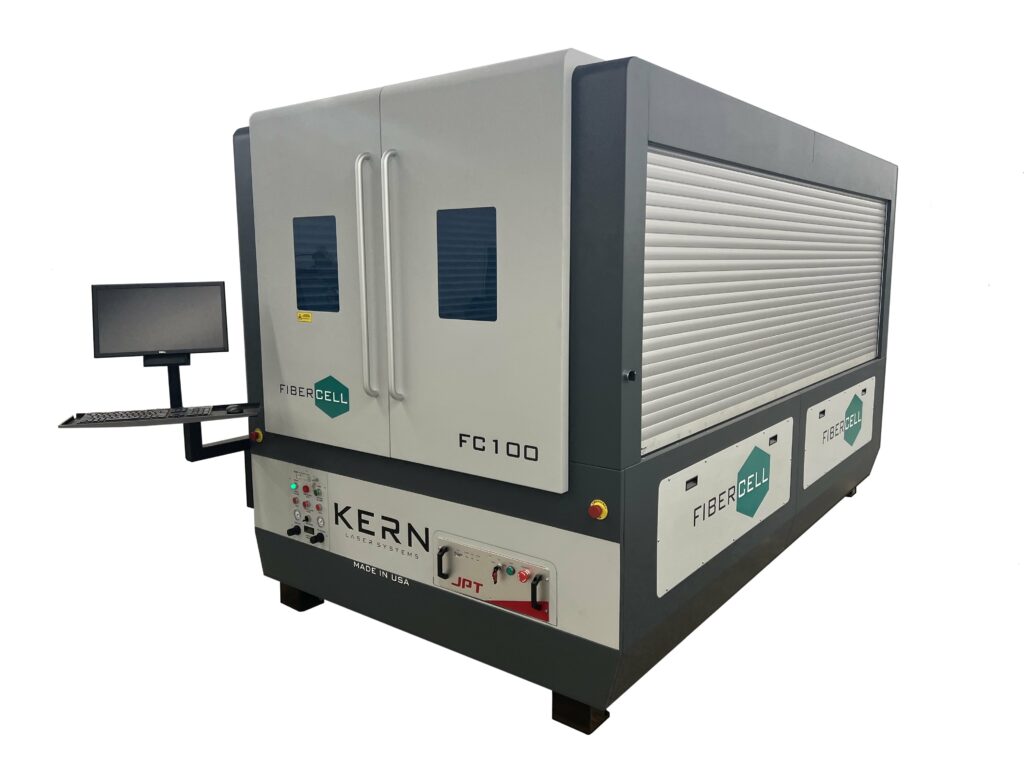

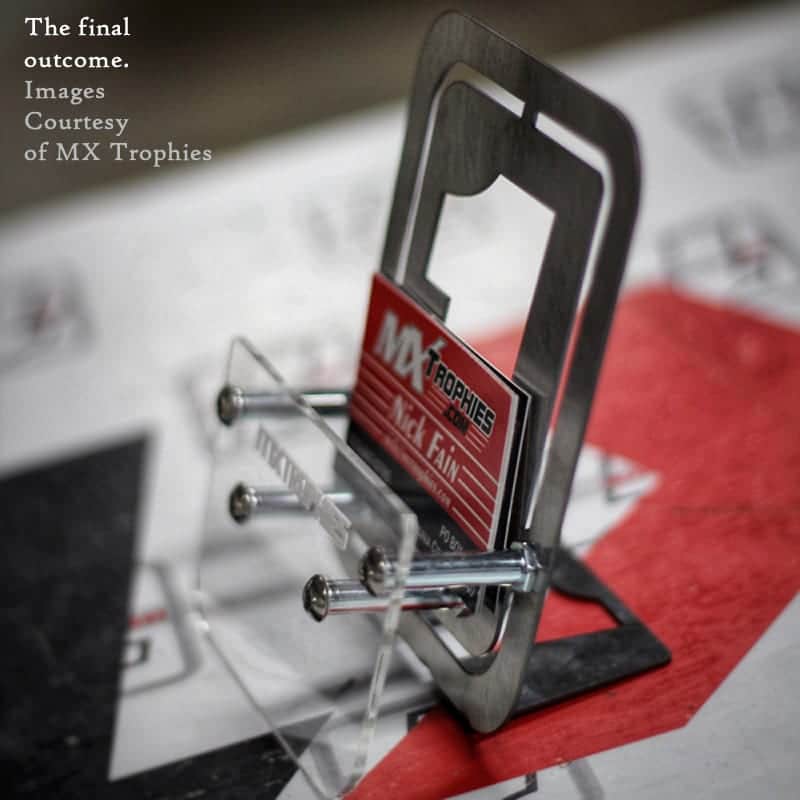

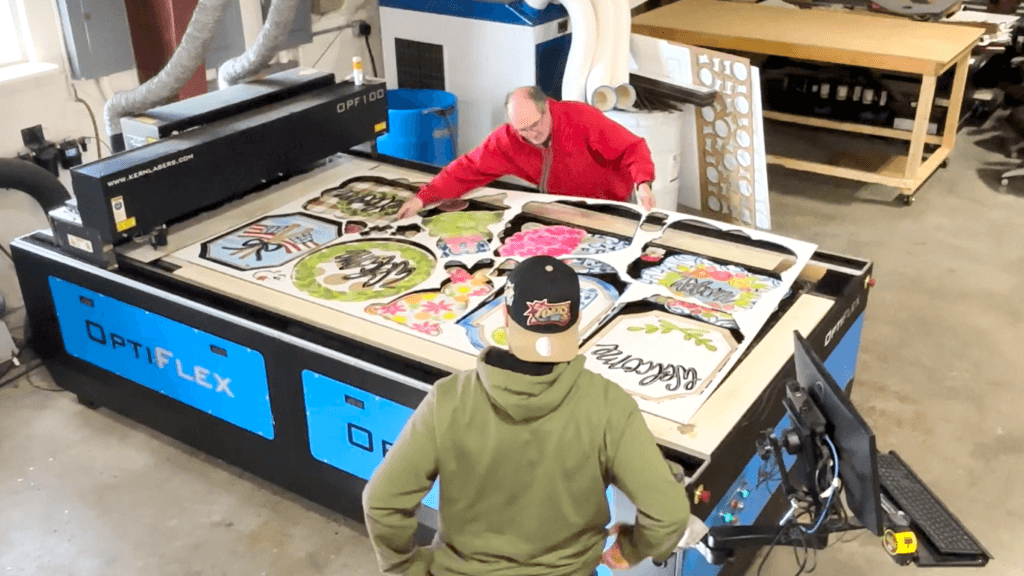

From Custom Cuts to Big Wins: Diverse Woodworking’s Success Story

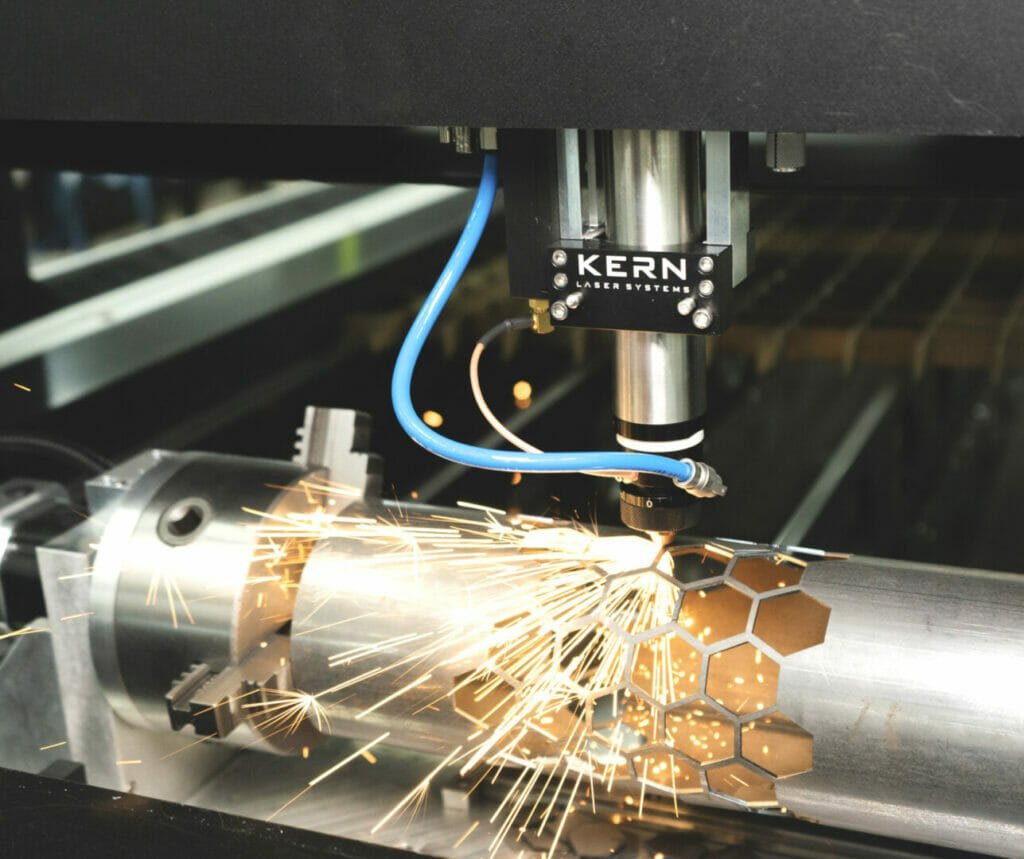

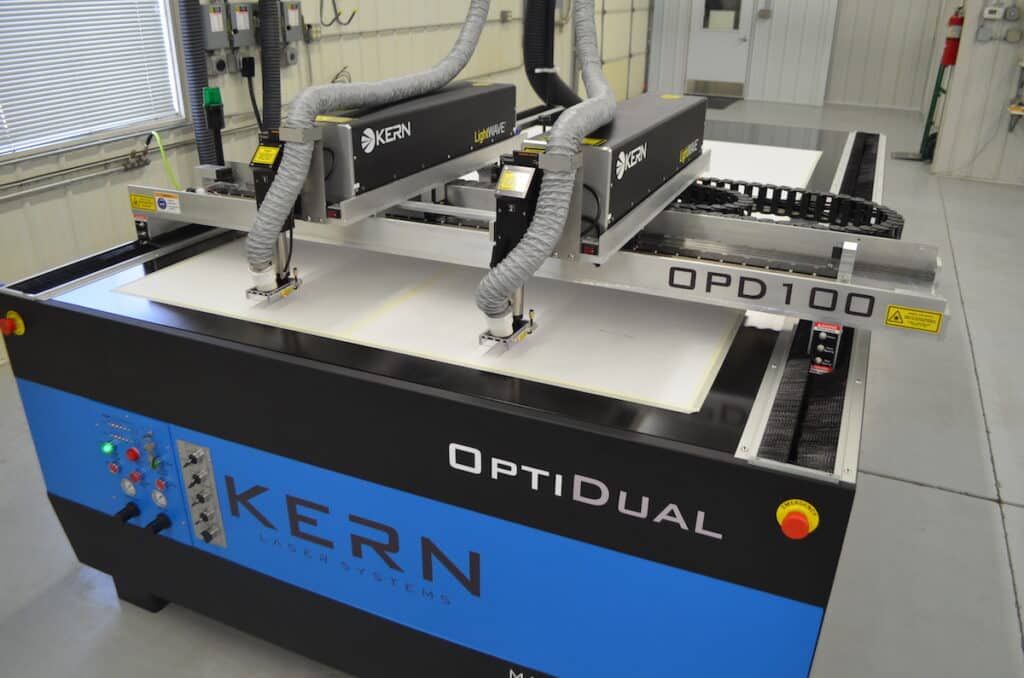

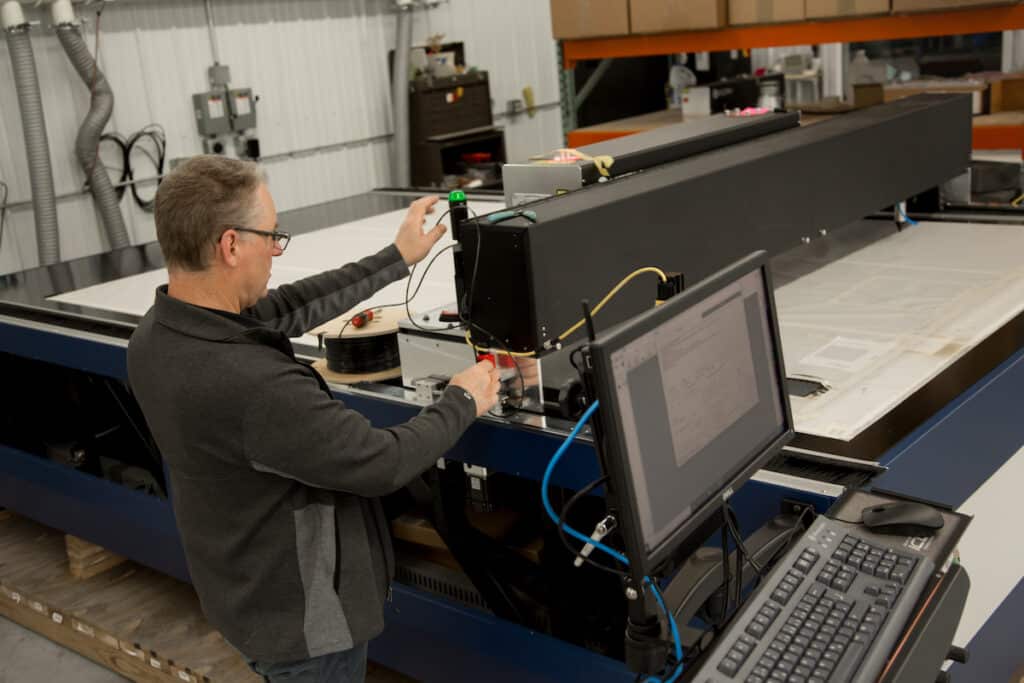

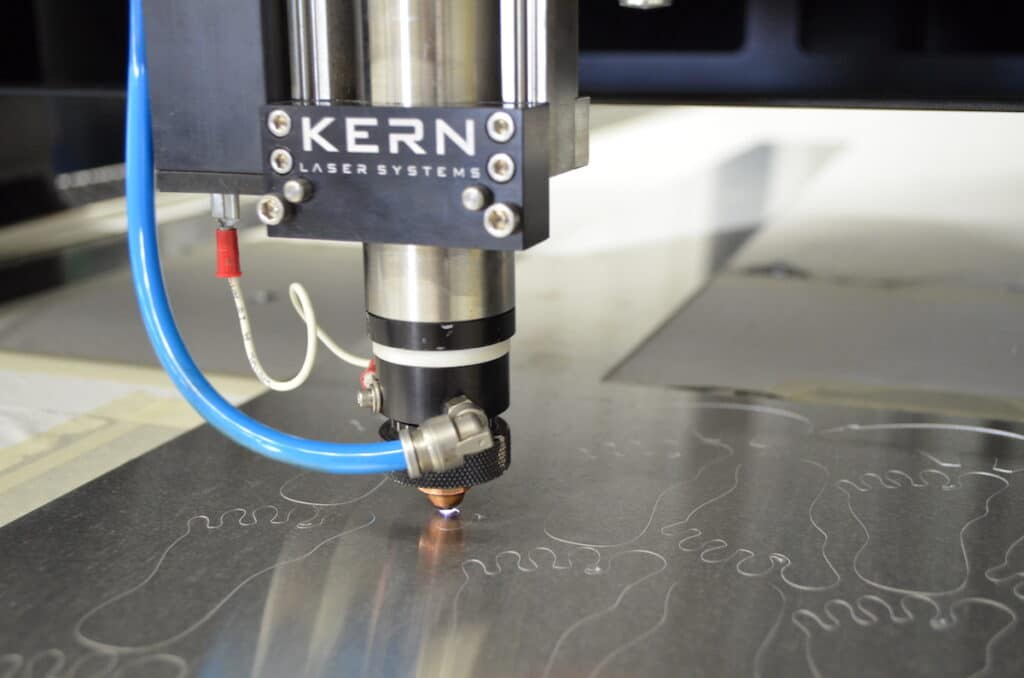

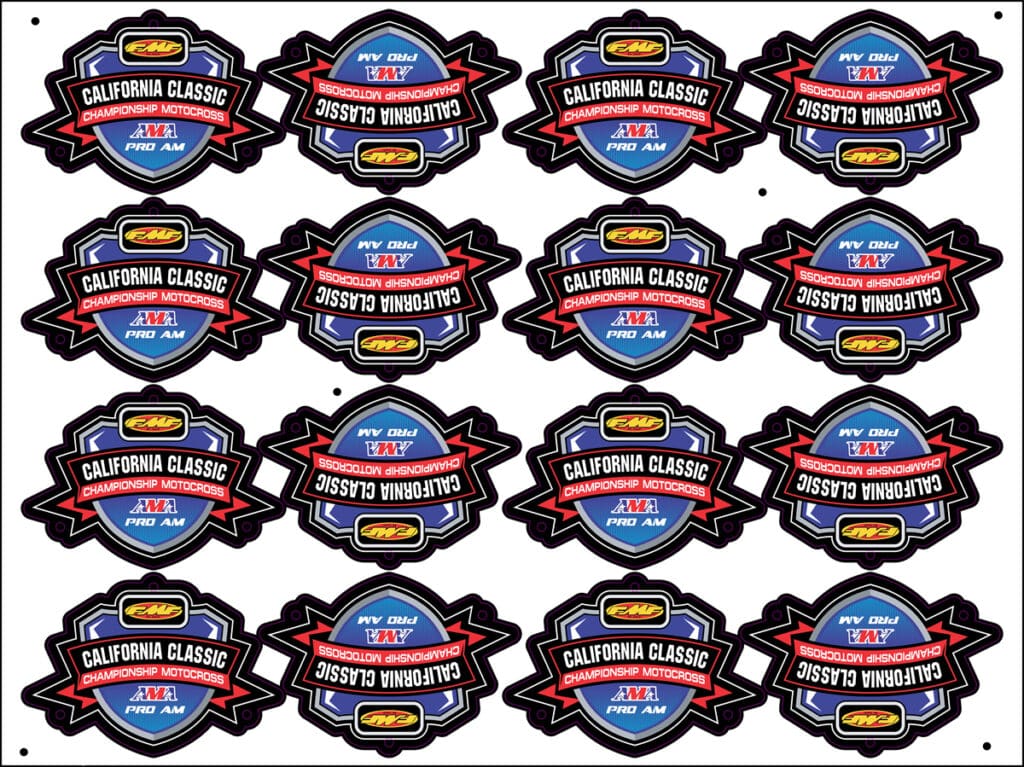

What started in a southern Indiana garage has become a nationally recognized name in the world of MDF cutouts and custom printing. Learn how Randy Elliott, CEO of Diverse Woodworking, transformed his growing business with the help of Kern Laser Systems, boosting precision, expanding production, and forging a partnership built on trust, reliability, and top-tier customer support.