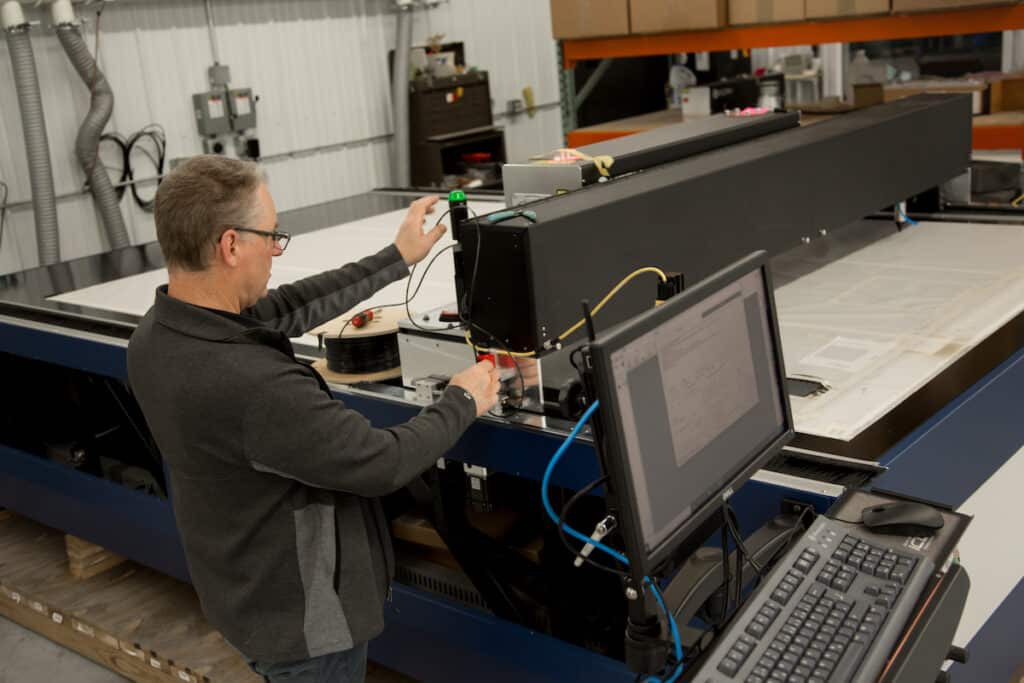

Who Uses Kern Laser Systems? A Look at Industries We Serve.

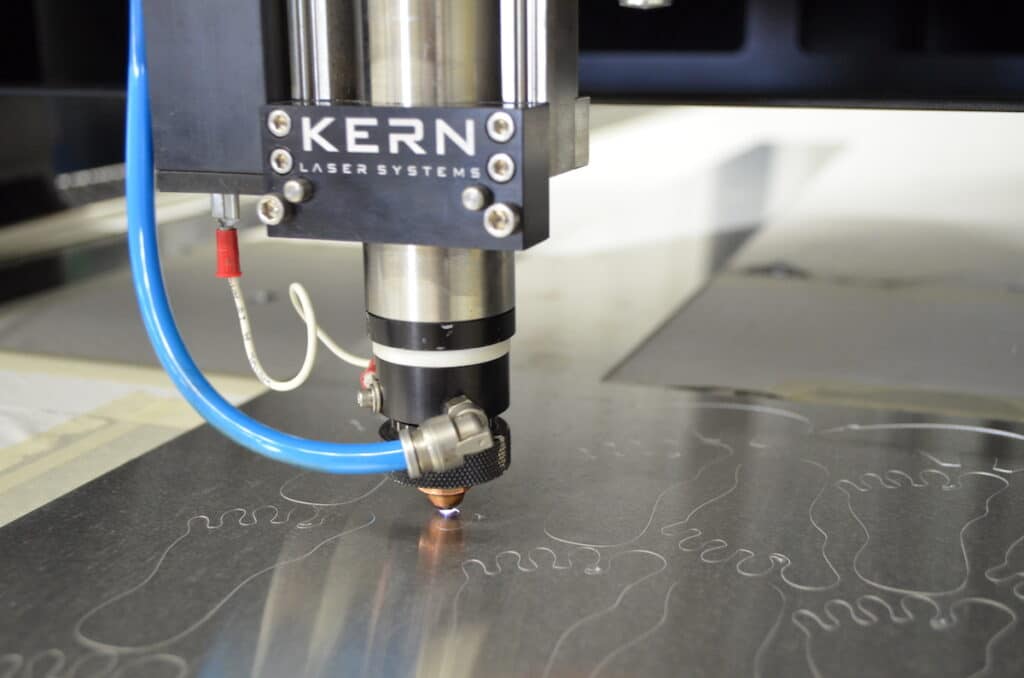

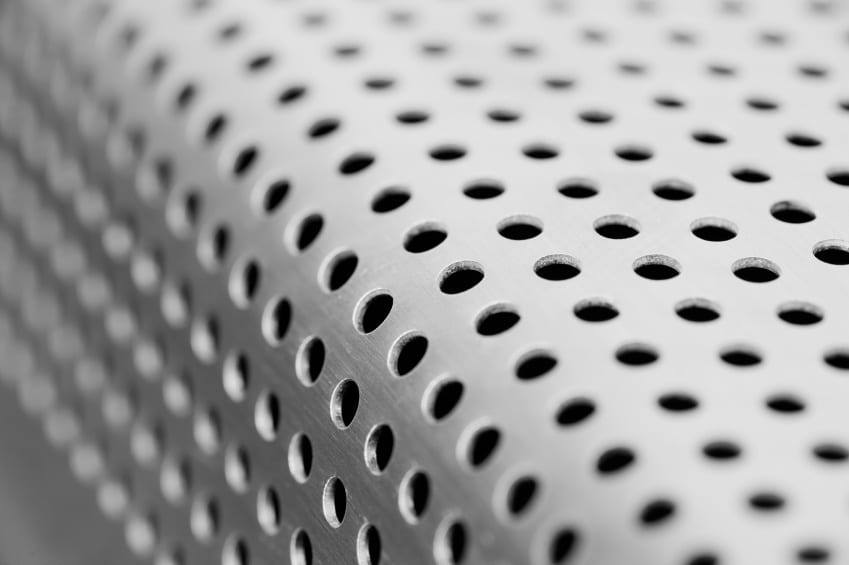

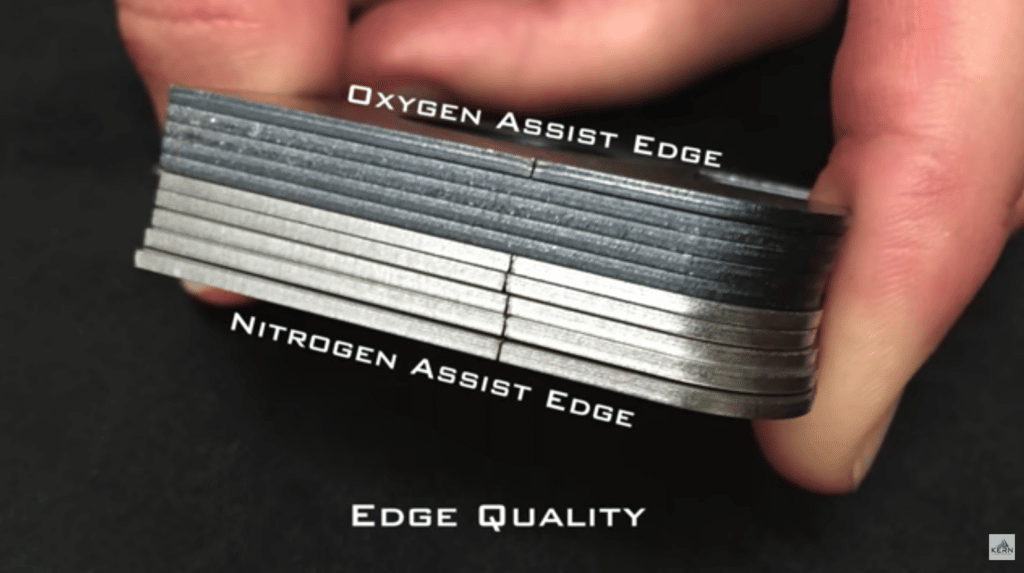

Kern laser systems are used within a wide range of industries. Here’s a list of the industries we serve, along with some examples of the materials and products lasers processed for these industries. AEROSPACE Within the aerospace industry, laser cutting is heavily relied on. Parts and components that go on to support aircrafts, military defense and space exploration rely on the accuracy, cleanliness and precision