Foam is one of the easiest materials to cut with a laser cutting machine, and Kern laser systems are some of the best machines you can buy for cutting foam.

Foam is lightweight, easy to work with, and practical for a wide variety of applications. It’s used in the automotive industry (most of the interior of your car is likely wrapped in a layer of foam underneath the upholstery), in the military, in boats, in insulation, in soundproofing, and in any number of other uses.

One of our favorite applications for foam is custom tool shadowing: Using a high-quality laser, you can create molded inserts for toolboxes to keep tools secure and organized. This is a major application the military uses foam for.

One of our favorite applications for foam is custom tool shadowing: Using a high-quality laser, you can create molded inserts for toolboxes to keep tools secure and organized. This is a major application the military uses foam for.

In addition to cutting into shape, foam can also be laser-etched. Part numbers, for example, could be etched into a foam mold for easy tracking and identification.

Since foam is so easy to work with, there are many other industrial tools that can work with it too, but lasers present many benefits over these other tools. Tools like routers or water jets create messes and waste that a laser does not. For very thick pieces of foam, you may need to use wire Electrical Discharge Machining (also known as wire EDM), but this is a much slower process than using a laser.

The results of cutting foam with a laser system are also more accurate and repeatable than other manufacturing methods. Cutting a flexible, porous material like foam with a blade is a little like cutting a marshmallow: Before the blade starts cutting the material, it will compress the material, altering its shape during the cutting process and reducing the accuracy and uniformity of the cut. Lasers are a no-contact manufacturing process, so a laser will not compress the material the same way; it simply slices right through. As an added bonus, lasers also seal the edges of cut foam, giving the final product a pleasing appearance.

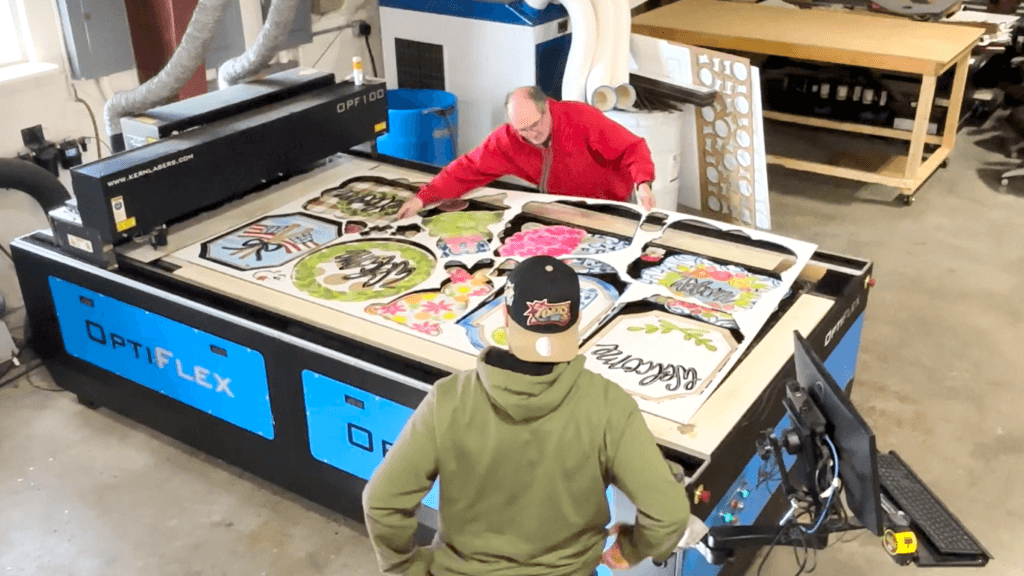

Our laser systems provide advantages for foam cutting over some of our competitors’ models. Any of our CO2 laser systems will be able to cut foam. Foam can’t be cut with a fiber laser, so a CO2 laser will be your best bet for foam cutting. Since the foam is so easy to cut, you can get by using one of our lower price models. But our larger format lasers provide an added advantage by allowing for entire 4’ x 8’, 5’ x 10’ and even larger materials sheets to be loaded onto the laser table without needing to be cut down to size first. This saves significant time and labor.

Testing any material you want to cut with a laser is important to optimize your machine’s performance and your product’s throughput, but testing can be even more important when you’re dealing with foam, given the wide variety of foam types out there. Foams can be layered, they can vary in density, and they can come in many different chemical compositions. All of these variations can affect a particular foam’s performance when cut or etched with a laser.

Foams that contain PVCs should not be cut with a laser because these foams can emit toxic chemicals when laser cut. Most other foam compositions will work well on a laser, but which of our models will work best depends on your specific material and application. The optimal settings for cutting foam can also differ depending on the composition and structure of the particular foam you’re cutting. High air pressure and a relatively long focal length lens work well with many typical foams, but this can vary, and more detailed settings require testing to determine. If you have a material you would like us to test on a Kern laser system, visit our Test Your Material page to get the process started.