When laser cutting an acrylic sheet, the last thing you want to see is an uneven cutting edge or surface — or even worse, your cutting kerf turning white while processing colored acrylic. Armed with a few quick tips, anyone can increase their skills in cutting thick acrylic with a laser cutter.

When laser cutting an acrylic sheet, the last thing you want to see is an uneven cutting edge or surface — or even worse, your cutting kerf turning white while processing colored acrylic. Armed with a few quick tips, anyone can increase their skills in cutting thick acrylic with a laser cutter.

Acrylic is one of the top materials chosen for laser processing. That’s partly because lasers can create such a stunning result. Other technologies, like routers or saws typically leave behind hazy or milky edge colors, requiring a secondary process to achieve flame polishing.

But that’s not the case with lasers. If it’s done properly, that glossy, flame-polished edge is achievable through a single process.

1. CHECK YOUR WATTAGE

For laser cutting thick acrylic, you’ll need a high enough wattage to get the job done. Thinner sheets, like ⅛ inch acrylic cut beautifully on 150w or 200W, but if you’re looking to cut one inch acrylic, you’re going to want a 250w or 400W laser.

2. REDUCE AIR ASSIST

Air assist will prevent your laser cutter from achieving a fire-polished edge and instead result in a frosted white effect. When air assist is reduced (we recommend using a wide nozzle to dissipate the air pressure) it lessens the chance to have a ghosting effect on the acrylic.

3. CHECK YOUR LENS

While most operators know they need a very low air pressure to achieve that fire-polished edge, they might not be aware of how dirty that can make their lens. A dirty lens is going to give operators a whole host of problems, from poor focusing to reduced laser power. Prevent these possible downsides by checking your lens daily or at least every other day if you’re cutting a fire-polished edge into acrylic.

4. FOCUS INTO THE MATERIAL

To achieve a more consistent beam width, adjust your focus toward the middle of the acrylic sheet. If the focus is on the top of a thick sheet, the laser will be out of focus by the time it reaches the bottom.

5. ADJUST YOUR FOCAL LENGTH

To get a laser to cut nicely through thick acrylic, it’s helpful to adjust your focal length so that the laser energy is concentrated. For instance, if you want to cut a half inch or one inch piece of acrylic, a longer focal lens is going to spread out the focus distance and give you a straighter cut. It will make the beam a little wider, but will prevent a slanted or uneven edge.

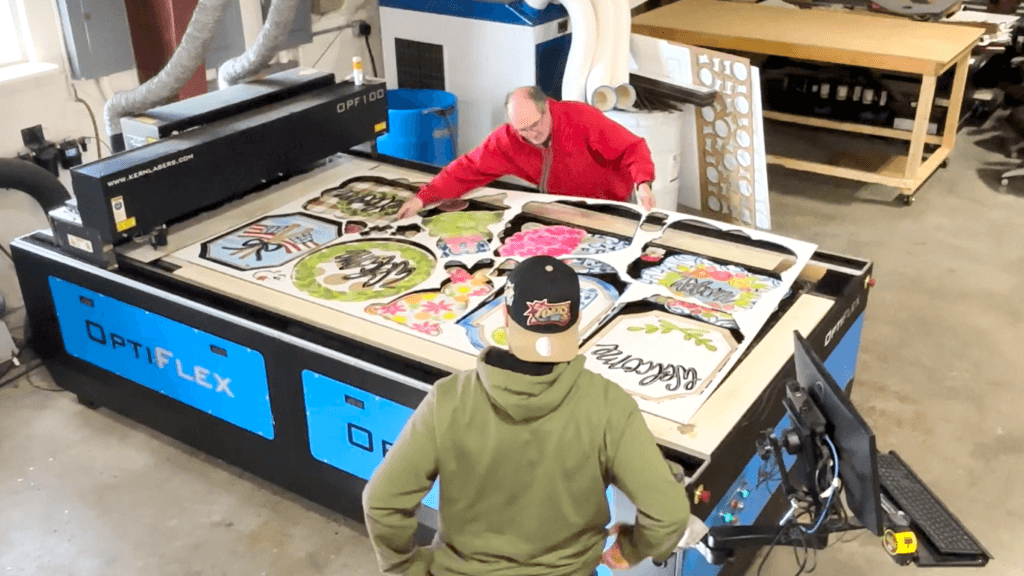

When you’re investing in laser processing, you deserve to see picture-perfect laser precision, but the reality doesn’t always live up to those expectations. If you’re interested in cutting thick acrylic, we can match you up with the Kern Laser System to meet your needs.

If you’re interested in seeing how Kern lasers cut acrylic, request a free sample kit.