Laser systems are a large investment. Especially the good ones. And just like any other investment, laser systems come with some responsibility. Routine maintenance provides two key benefits:

- Keeps the laser system running properly and producing parts to the best of its ability

- Prolongs the life of the system components to increase ROI

Paying attention to maintenance supports both the well-being of the laser machine and the quality of the items it helps to produce.

The best part? Laser systems are pretty simple to maintain.

On the whole, there’s very little maintenance required. But, by completing the little bit of maintenance there is, owners and operators can help decrease the chance to have costly CO2 laser repair services.

LASER MAINTENANCE 101

LASER OPTICS MAINTENANCE

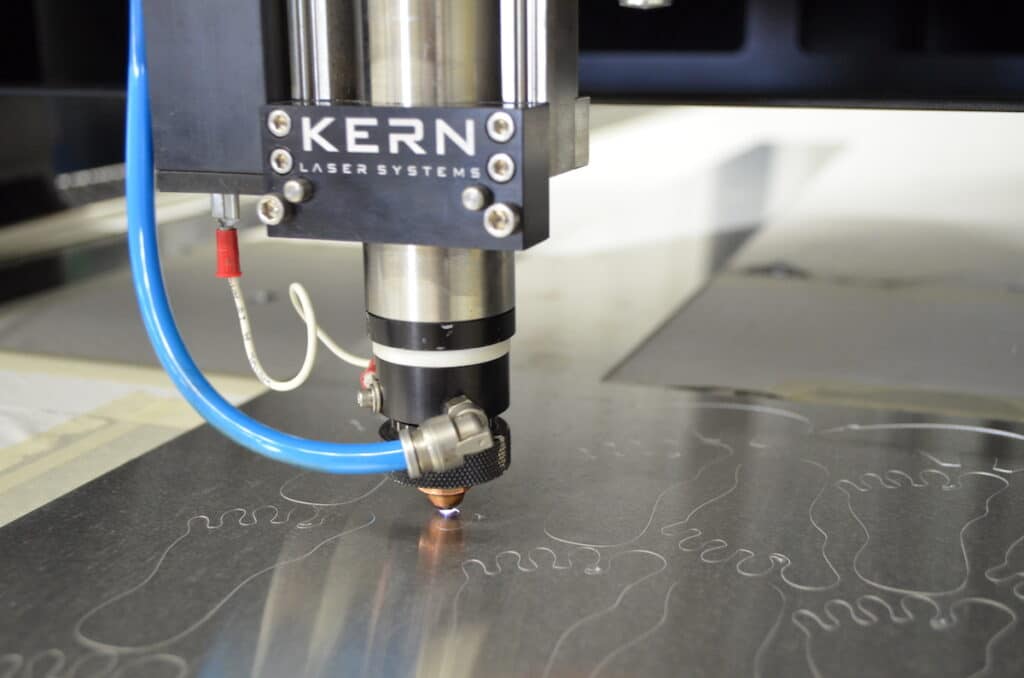

Without proper settings or with heavy use, the optics of the laser system can become contaminated with smoke or debris. And when they’re dirty, they can cause poor focusing and reduce the power of your laser. These problems lead to diminished cutting and engraving quality.

Left unattended, dirty optics can lead to cracked and burned lenses. If that happens, not only will you have to stop processing, you’ll have to purchase replacement parts too. But this can all be prevented with a bit of routine maintenance.

Optics are one of the most critical parts of the laser system, so give them adequate care in your maintenance schedule.

LASER CHILLER MAINTENANCE

If temperature controlled water isn’t circulating through the laser source, you run the risk of overheating the laser tube. In other words, it can put you on the fast track toward laser failure, unnecessary downtime and ultimately a costly repair.

By properly maintaining the chiller, which mainly means keeping it clear of debris and replacing the water every six months or so, you’ll help to preserve the laser tube and the laser’s output power.

You can learn more about laser chiller maintenance in these videos I put together a little while back. They feature maintenance tips for our Polyscience and S&A chilling units.

At the end of the day, a little attention to the chiller can help to extend the longevity of your laser system and prevent downtime.

LASER RAIL AND TRACK MAINTENANCE

Another important area of the laser system that deserves some consideration is the motion system mechanics. The x-axis rail guides need to be oiled regularly — this ensures the gantry has a friction-free path to move quickly during processing. The y-axis also consists of linear guide bearings that need lubrications to prevent premature failure. These efforts will keep the moving parts of your laser system from wear.

HOW TO PLAN FOR LASER MAINTENANCE

Laser system ownership comes with the responsibility of care and maintenance. The manual that came with your laser system should include maintenance directions, as well as a maintenance schedule. It is always best to follow the manufacturer’s directions as it relates to maintenance.

It’s also important to note maintenance requirements are typically based around hours of operation, so whether your system is running on one, two or three shifts per day will impact its maintenance schedule. So will the cleanliness of your shop and the materials you process most often.

Proper system maintenance will help protect your purchase, and decrease the chance for costly laser repairs.