Often when we talk about manufacturing with lasers, we focus on cutting or engraving rigid industrial materials like sheet metal, plastics, or wood using powerful CO2 or fiber lasers. But CO2 laser cutters can also be revolutionary for cutting fabric and textiles. Let’s take a look at the benefits of cutting fabric with a laser, as well as considerations for optimum fabric-cutting results.

Benefits of Laser-Cutting Fabric

Laser cutting saves a tremendous amount of time compared to traditional techniques for cutting fabric. It offers more repeatability than traditional cutting methods, making for a more consistent product during large-scale production.

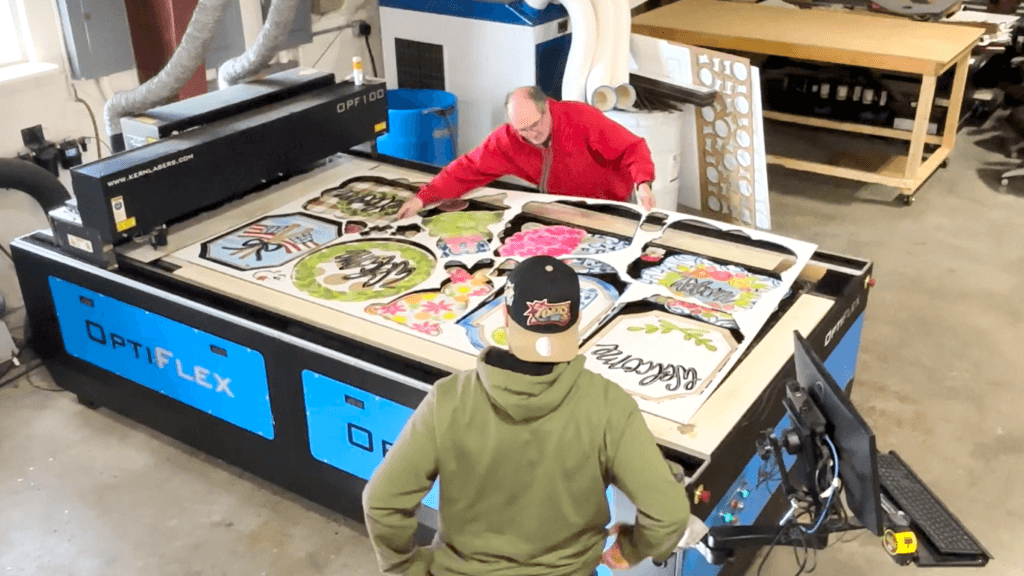

Laser cutting is a no-contact manufacturing method: No cutting tool touches the fabric, and the fabric does not need to be clamped or secured to the cutting table. Few moving parts mean less maintenance for the machine and reduced wear and tear on the tools involved. Workers don’t need to be in direct contact with the product during processing; they may even be able to perform other tasks while the laser operates.

The reduced labor and increased consistency and efficiency of laser cutting mean, in the long run, that these machines often substantially reduce users’ production costs, despite the high initial investment involved in acquiring a laser cutting machine.

The laser also melts and seals the edge of the fabric during cutting, which prevents fraying and eliminates post-processing steps.

How Much Power is Required?

Any Kern laser would be able to cut fabric with high levels of speed, quality, and precision. A 100-watt laser can cut most types of fabric at top speed. The optimal wattage for cutting fabric is probably somewhere in the range of 100-150 watts, but even our much more powerful laser systems would be fit for the job thanks to the exceptional power control they offer. If you buy a larger wattage laser, you can still lower the power to process this material.

You would use 30-40% power to cut fabric on a 100-watt laser, and smaller percentages of power on a more powerful laser. Make sure the laser you choose can operate at low power effectively if you are buying a more powerful laser and intend to cut fabric at low power. Any Kern laser system will be able to do this, but some of our competitors’ lasers would not operate well at such low power settings, so your realistic choices for a laser that could cut fabric and cut other materials would be more limited in their product ranges. Our lasers can run effectively at settings as low as 3 or 4 percent power.

What Fabrics Can I Cut with a Laser Cutter?

Fabrics suitable for laser processing include the following:

- Cotton

- Silk

- Felt

- Leather

- Polyester

- Linen

- Nylon

- Hemp

- Denim

- Lace

- Microsuede

- Velvet

- Fleece

- Microfiber

- Carpet materials and carpet tiles

- Softshell

- Synthetic leather

- Velour

- C

The same laser cutting head can be used for a variety of fabrics—linen, nylon, hemp, polyester, and denim, among others—with only minor changes to its parameters. Even delicate fabrics like silk and lace can be flawlessly cut using lasers. No tooling changes need to be made to the laser cutting machine when switching between fabric types or fabric shapes. This saves the user time and money that might have been spent on different kinds of cutting tools.

Many of these fabric types can also be laser-engraved by putting the laser on a low-power setting to leave a design rather than cut through the fabric.

One consideration when it comes to cutting fabric with a laser is the composition of the fabric to be cut. Most fabrics and textiles will work just fine, but there are a few to be avoided, namely any synthetic materials that contain certain types of plastics or PVCs, which, when cut with a laser, can send off toxic fumes. Fabrics that have a heavy degree of plastic or glue can also become stained when those substances melt during laser cutting. It is important to know your material when buying a laser-cutting machine.

When cutting white fabric with a laser, there is also the potential for overburn; however, with our lasers, the air pressure can be used to mitigate that. 60-70 psi air pressure is important when cutting fabrics, both for avoiding undesirable cutting artifacts like overburn and for keeping the material flatter and wrinkle-free during processing. (This helps ensure the cutting is precise.)

To ensure one of our laser systems will work for your desired job, we offer to test clients’ materials on our machines. This can allow you to compare our products’ performance against competitors. We can also determine optimum laser settings for your material and offer our suggestions on how to streamline the cutting process to maximize throughput.