In CO2 laser systems, there are two common types of power supply that can be used to excite the gas molecules in the laser module: direct current (DC) and radiofrequency (RF). In this article, we’ll take a look at the differences between these two power supply types.

What is a DC Laser?

What is a DC Laser?

DC power (the same type of current used in battery-powered devices) is typically used in lower-end glass tube lasers. The glass tube contains the laser gas mixture, and the optics are mounted directly to the glass within the tube. A high-voltage direct current is sent through the tube via electrodes to excite the gas mixture inside the tube, which produces a beam. The beam first pulses back and forth within the tube and then exits the tube at one end once it hits a certain energy level.

What is an RF Laser?

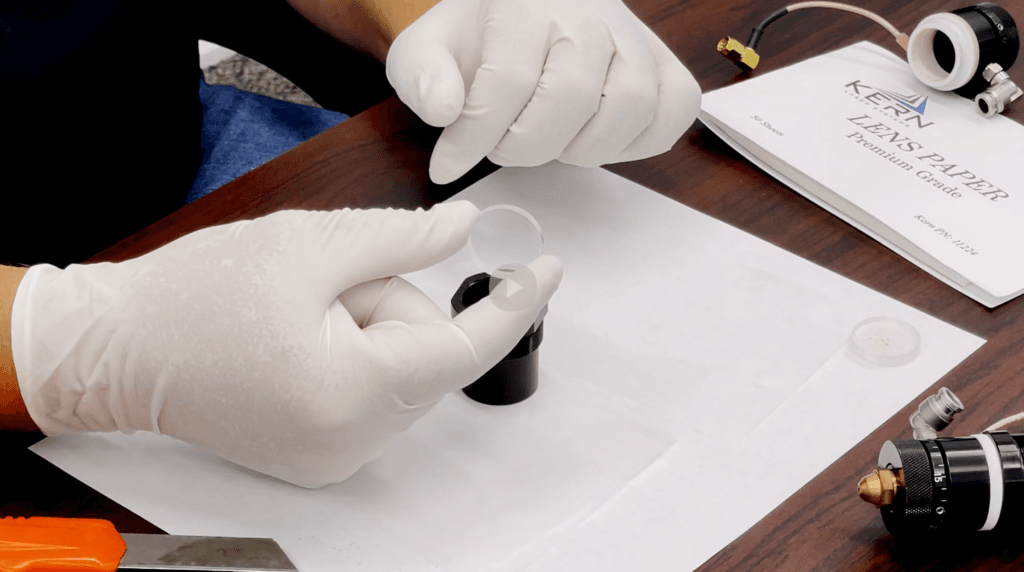

The gas mixture of an RF laser is contained within a sealed metal cavity. RF energy excites the gas molecules to a level where photons are emitted from the laser cavity creating the laser beam.

Comparison

The two power supply types are not created equal. Here at Kern, all of our laser systems are metal-sealed RF lasers. It is the best option for our customers’ applications.

RF lasers are a technology that continues to develop today, while DC lasers are to some degree outmoded. DC lasers are short-term, lower-lifetime, disposable lasers. They require more frequent replacement, hopefully after a year or two, sometimes after only a matter of months. But they are substantially cheaper than RF lasers.

The power rating of an RF laser will remain more constant than that of a DC laser with use over time. DC lasers tend to lose output power as the gas mixture slowly becomes contaminated. This will gradually slow the pace of laser processing over the course of a DC laser’s life.

Switching speed and pulse speed is slower for DC-powered lasers. The faster pulse speeds of RF-excited lasers enable greater quality of detail in engravings. This kind of quality is not possible with a DC laser, where noticeably scorched and ragged edges will be more common. RF allows for a smaller, more power-dense beam, which can allow for higher-quality cuts with less debris and fogging.

Kern lasers have large gantries, which require an RF-powered laser in order to achieve the kind of high pulse speed required for engraving work, whereas high pulse speeds with a DC laser are not possible. On a DC laser, you might be able to get a satisfactory result on a simple engraving, but for the same (or better) quality on a high-end scale, you would need an RF laser like ours.

RF lasers are also able to operate effectively at much lower percentages of their total output power than DC lasers. This is another factor that suits them for intricate engravings; they can be set to very low power. Many DC lasers will not perform reliably at a very low power setting.

Who Should Consider Each Type?

In spite of their numerous shortcomings compared to RF lasers, DC lasers can be an appropriate choice for a smaller market with a limited budget, where the task at hand is only cutting or simple engraving work. They are more geared toward hobbyist, small-scale applications than for a professional shop that needs to have steady, reliable output. For most other users, an RF laser is going to be more appropriate.

Many of our clients need to be highly productive, and they want their lasers up and running. They want to turn their machine on and have it work with no headaches or breakdowns. This kind of stress-free operation is more achievable with an RF laser than with a DC laser. DC lasers’ shorter lifespan means they are more likely to experience downtime for replacement than an RF laser. The less-consistent output power over time of a DC laser is also a consideration for this kind of user.

Even if a DC laser is appropriate for the work you want to do, the much higher rate of replacement for DC lasers coupled with their relative lack of repairability may still mean an RF laser is the better choice–RF can be cheaper in the long run.