Finding the Right Laser System

Understanding ROI for a Big Purchase

We get it. It’s no small task investing in a laser system. When your industry relies on precision laser technology, choosing the right system involves more than just picking a model with the latest and greatest features. It’s about making a purchase that aligns with your business needs as well as a strong return on investment (ROI). Here’s how you can evaluate your options and ensure that your investment pays off in the long run.

Assess Your Needs and Applications

Before diving into the laser systems market, determine the needs specific to your business:

- Will you need a CO2 or fiber laser?

- There are all types of lasers on the market. (UV, Fiber, CO2, Diode, and more), If you are new to lasers, understanding the differences is just a phone call away. The easiest and quickest way to find out what laser type may work better for your application is to talk to a laser sales associate. The type of material you are wanting to process will determine the laser type you need.

- What materials will you be working with?

- Kern Laser Systems offers potential new customers the chance to send in their materials/applications to be test cut on our machines before purchasing. This allows us to narrow down the precise technology and parameters to achieve the best finish for your product; also allowing for actual processing times to be factored into your decision making. We’ll send those samples back to you to review the quality and decide if you want to proceed with the purchasing process. Our sales team can help identify the best type of laser suitable for your materials and also if a certain wavelength is required to achieve superior results.

- What level of precision and power output do you require?

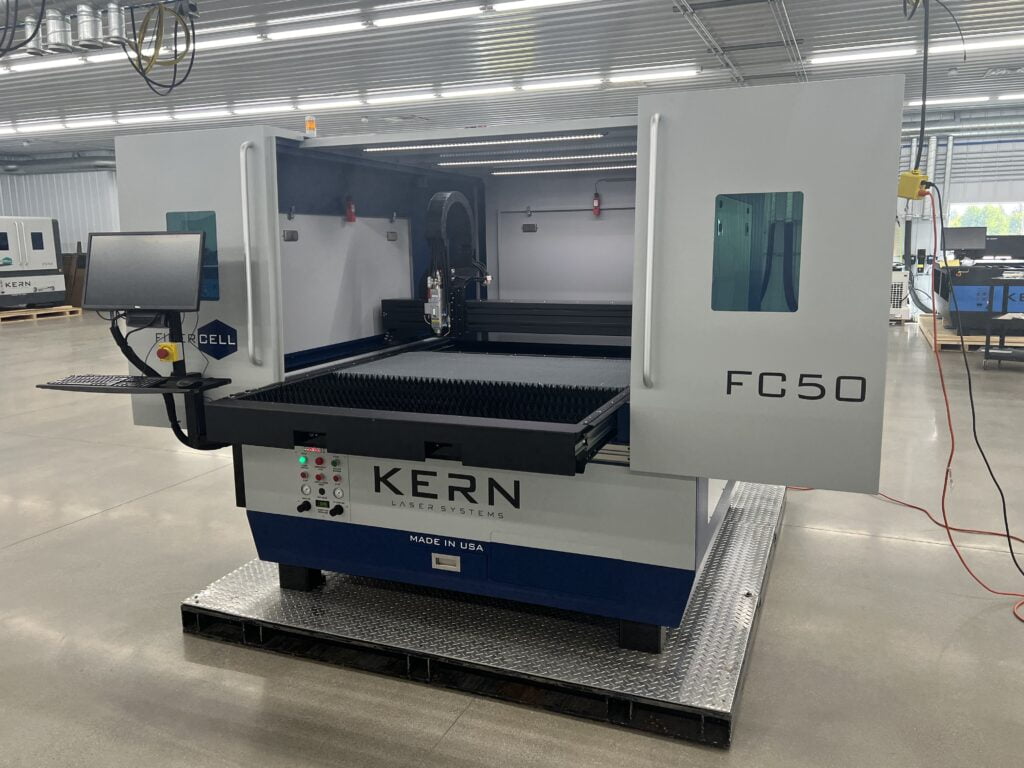

- Kern Laser Systems offers CO2 lasers from 100 to 650 watts. When considering a fiber laser wattages range from 1kW to 3kW. After testing, a sales associate will work with you to determine which laser wattage and size of table best fits your budget and processing needs.

- How often will the system be in use?

- Kern’s laser systems are built to last, using high-quality motors and durable components designed for longevity and reliability. We take pride in the fact that many of our first laser systems from the late 90s and early 2000’s are still in operation today, a testament to the exceptional craftsmanship and engineering that go into every machine we produce. By using top-tier parts, we ensure that our systems deliver consistent performance over the years, giving our customers confidence in their investment.

Understanding these factors helps narrow down your options to laser systems that are truly suitable for your application.

Compare Initial Costs vs. Long-Term Value

The upfront cost of a laser system can be a large investment, but the true cost extends beyond the purchase price. Consider:

- Operating Costs: Energy consumption, maintenance, and replacement parts. Kern Laser Systems offers maintenance cost charts for each laser type that can help with the analysis of operation costs.

- Throughput & Efficiency: A higher performance machine that operates faster and requires less maintenance may be more cost-effective in the long run.

- Lifespan & Durability: An entry level or imported system will often require frequent repairs and can end up being more expensive over time.

Calculate the ROI of Your Laser System

To determine whether a laser system is a sound investment, calculate the expected ROI using the following approach:

- Revenue Increase:

- Estimate the additional revenue the laser system will generate by:

- Improving production efficiency

- Enhancing product quality

- Expanding service offerings to new markets

- Estimate the additional revenue the laser system will generate by:

- Cost Savings:

- Factor in reduced labor costs, material waste, and increased operational efficiency. A high-quality laser system can automate tasks and reduce errors, saving time and money.

- Break-Even Point:

- Divide the total investment by the annual profit generated from the system to determine how long it will take to recover the initial investment.

Consider Support and Training

Buying a laser system isn’t just about hardware—it’s also about the support you receive.

Kern Laser Systems offers:

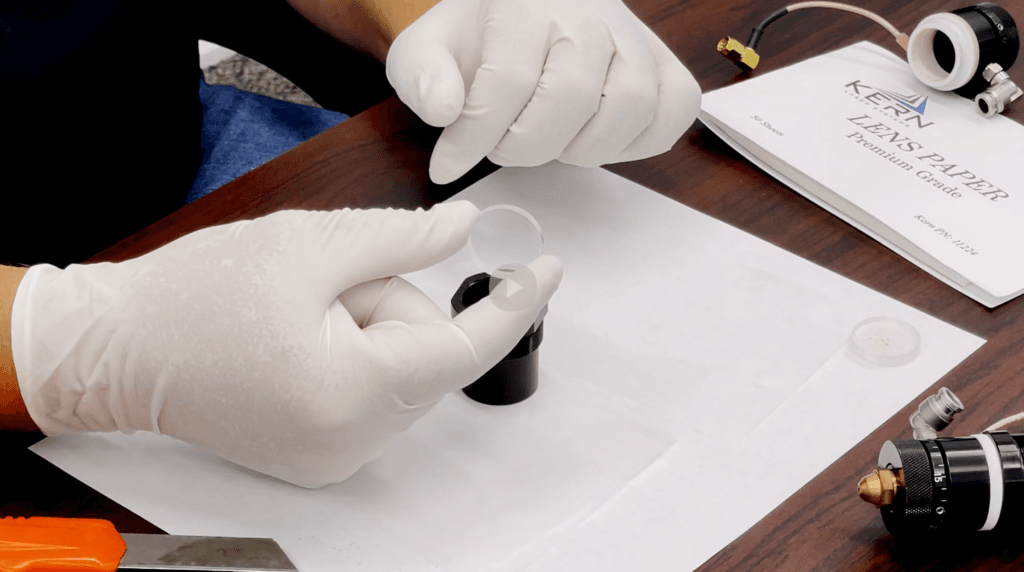

- Comprehensive training, either at our facility or on-site at your facility.

- Reliable customer support. No calling trees. You speak directly with our technicians and sales team.

- Warranty and maintenance services.

A well-supported and maintained machine minimizes downtime and ensures you get the most out of your investment.

Future-Proof Your Investment

Technology evolves rapidly, and so do customer demands. Select a laser system that allows for upgrades and flexibility, ensuring it remains useful even as your business grows.

Final Thoughts

Purchasing a laser system is a significant investment, but with careful evaluation of costs, benefits, and long-term ROI, you can make an informed decision that drives profitability. By selecting the right machine for your needs and optimizing its use, you can maximize efficiency, reduce costs, and gain a competitive edge in your industry.