For small business owners and entrepreneurs, it can feel like long days and late nights spent working is just part of the gig. But sometimes, getting more done doesn’t have to mean working more time. In fact, by investing in the right equipment, it’s possible to improve manufacturing efficiency and give yourself some much needed time to breathe.

HOW TO IMPROVE MANUFACTURING EFFICIENCY

While it’s true there are only so many hours in the day, there are ways to get more done in the time available. For many, increasing manufacturing efficiency is something that sounds good but seems impossible. After all, if it’s all hands on deck, what else can be done?

Here at Kern Laser Systems, we’ve seen countless individuals improve manufacturing efficiency by using a laser system.

AUTOMATE MANUAL PROCESSES

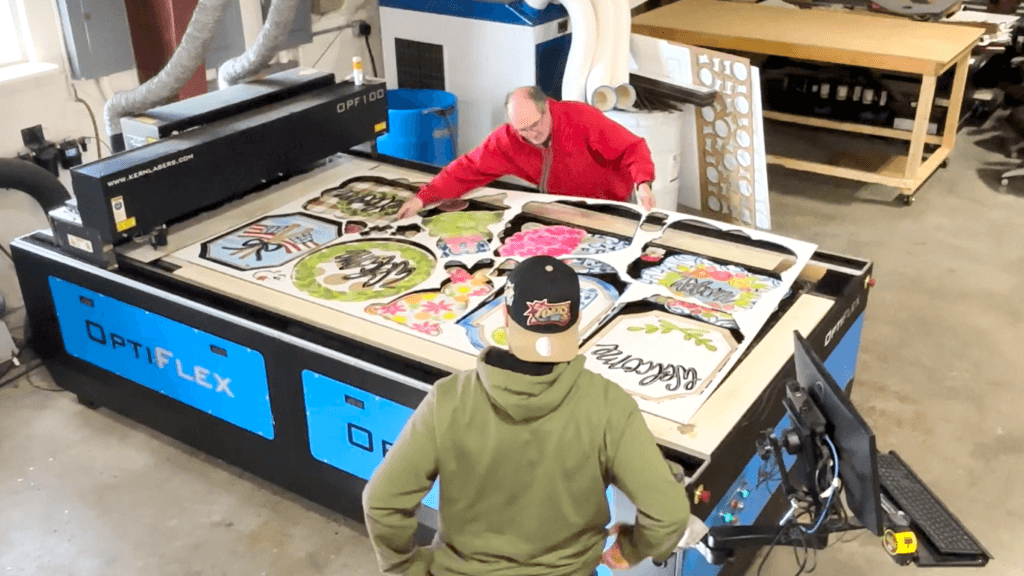

Automating manual processes is a great way to increase manufacturing efficiency. Take, for instance, cutting. If your trade or production efforts include manually cutting materials like aluminum, fabric, foam, leather, wood or some other material, imagine how things would change if that cutting was automated and accomplished using a laser cutter? For many, a switch like this would be revolutionary for their production numbers.

For example, say you’re a manufacturer of engraved wooden coasters. At first you started out as a small etsy shop, doing the engravings with a CNC, after a few months your demand has reached a level where you now have multiple back-orders, a wait-list, and are losing customers due to not being able to meet the demand fast enough.

You are now overwhelmed with work and unable to catch-back up which not only takes a toll on your business, but also on you as you spend more and more time engraving coasters to try to meet the demand.

Now imagine if you purchased a laser to do the engraving for you.

You could do multiple coasters at-once with only a small amount of finishing after the laser was done. You would be more efficient, enabling you to meet, and even exceed, demand. This would allow you to continue to grow your business, and allow for free-time to spend with family and friends.

The best part, a laser system increases efficiency and productivity immediately.

DOUBLE YOUR PRODUCTION CAPABILITIES

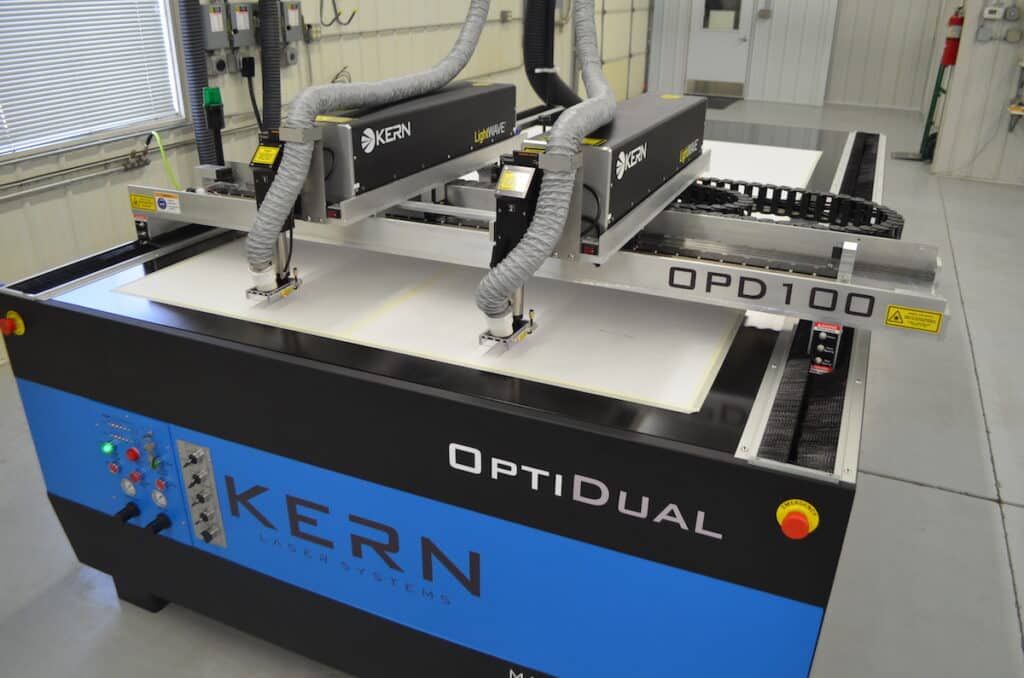

For manufacturers looking to increase production efforts, another option is to invest in a dual-head production laser cutter like the OptiDual., Dual-head production lasers make it possible to increase production yield by doubling down on laser processing. Here’s a quick video of the OptiDual in action:

As you can see, the OptiDual operates with two nozzles mounted on a single gantry. They work side-by-side, cutting the exact same shapes and patterns. For industrial-scale production, the OptiDual is an excellent option.

ACHIEVE MANUFACTURING EFFICIENCY WITH KERN LASER SYSTEMS

A Kern laser system provides owners and operators with the capabilities to increase manufacturing efficiencies, allowing you to accomplish more in less time.

Try out the laser fit tool to help determine which Kern laser system fits with your laser processing needs.