Cabin Digital LLC is a small company in Fredericksburg VA. We provide rapid prototyping services to the government and commercial clients. About 18 months ago we made a decision that a CNC laser cutter/engraver might be a good next tool to complement our CNC Plasma cutter, 3D printer and the rest of our team’s tools. That started our journey and we share this with our fellow potential Kern users. Cabin Digital LLC was founded by my wife as a logical growth of another business she owns. While we are a small company with about 20 folks most of us are seniors in major corporations, I’m the CTO for a 3 billion dollar defense contractor. So while we’re small we like to think we had some really smart folks on our team and that helps when you make big decisions. For a small company buying a CNC Laser is a big decision. For Cabin Digital it would be one of our larger assets. We did our research and really came down to two choices–a Kern system or a Chinese produced system. We looked at the specs and the Kern was clearly a better system. We looked at the price and for Cabin Digital we had a really hard time justifying the significant price difference between the two systems. We did as much research as possible even looking for used Kern systems. Finally we decided that the Chinese Laser was the best option for us and then placed an order for about $25K.This is when the reality of the challenges became clear. The company sought payment via PayPal and needless to say we felt concerned dealing with global transfers of money to China. We were committed and said as a team I hope we actually get a machine–not a good feeling. About 2 weeks passed and we were contacted to arrange customs clearance. Now we were a bit surprised because our deal included shipping… Shipping yes but customs no… We then spent about two weeks finding an agent and providing all of the use papers. The Chinese company offered to declare the system “parts” we declined not desiring to commit import fraud. Sure we want to save money, sure we thought these costs were included but we’re not going to break the law. We negotiated a tailgate delivery as we didn’t have a forklift at our shop were the laser was being installed. Big mistake! They sent the system it made it across the ocean and arrived at our shop about 2 months after we paid for it. The driver backed up with his lift gate truck and said how are you going to unload this? I said lift gate right? He replied it’s too big for the lift gate…With some quick scurrying we got the tractor with forks (no forklift) and combined the lift gate with the tractor to get the crates out–so much for “free” shipping. We unloaded and got the machine in place. This was a large 1200mm x 1600mm 150W CO2 system and included the chiller and associated accessories. Wait, where is the honeycomb? Where is the rotary option? Several emails later and eventually I had to provide a copy of their email to them with those promises. That resulted in a request for me to pay additional shipping and customs–my reply no! I offered to have the machine returned at their expense and suddenly they sent the “extra” parts. Now on to machine setup…we had a space ready and quickly had the machine in place and the vents, power and air. The machine didn’t have a computer with it–you provide that but the software and software key were included so we hoped that would be easy. First we powered up the system and the laser head moved to the back right corner and when almost there sounded an alarm and shutdown. We looked and tried a restart and had the same problem. A few days and a few more emails and we had a cause–seems a proximity sensor has been tilted and needed to be bent back into place. Not good but at least it was easy to fix. The system also allowed the blowers to be controlled through switched outlets and we plugged them in and tested that–low and behold the fans power up and then stopped… Go to the back of the machine and what do you find old style push and turn buss fuses. Both blown… Replace repeat, replace repeat and decide to finally replace with two breakers. Looking inside the machine these wires for the fans are clearly undersized–not to mention that the outlets don’t have a ground pin…Our decision we’ll power and control the fans outside the system. It works and it’s easy… On to software. We have a clean XP machine and load the software following the scattered directions. All seems fine and we try to connect to the machine and get driver errors… For a minute I was transported back to the 80’s when every computer device seemed to complain and tell you to contact the vendor… A two-week session of emails and lots of trials and errors suggested that the controller or display was bad and they would send a new one… Ok wait on DHL and soon we have a controller and do the install and test… Guess what same problem… Another 2 weeks of emails and even some YouTube videos sent to the company and still no answer. Cabin Digital is an engineering company and has a few good software developers. Up to this point we doubted ourselves. Were we were doing things wrong or did we have a hardware problem? After a bit of file-by-file inspection it became clear the machine shipped with the wrong configuration files and was trying to configure incorrectly. We asked for the correct files and after a bit of “You should have that”, “We don’t”, they sent the right file. About three months and untold hours we were finally up and running. The laser was finally cutting and engraving and earning its keep. Overall it did a pretty nice job, of course we didn’t have a comparison. We were excited that the system was working and as we learned the software things settled down. We run the machine for about a year and over that time replace a lens and mirrors based on debris but again we didn’t have a reference point. About once a month the laser required an alignment that takes about 2-3 hours to get right… The mirrors have classic springs and screws but when you tighten the jam nuts the alignment changes–it was a long trial and error to get the alignment process to work across the entire table. It never cut perfectly everywhere and occasionally we would have to recut one part. That slowed us down as we couldn’t confidently cut and entire sheet or engrave a large area with consistency. Still we pressed on and in a year our laser business was growing–actually growing so well these problems were beginning to be a big pain.

Cabin Digital LLC is a small company in Fredericksburg VA. We provide rapid prototyping services to the government and commercial clients. About 18 months ago we made a decision that a CNC laser cutter/engraver might be a good next tool to complement our CNC Plasma cutter, 3D printer and the rest of our team’s tools. That started our journey and we share this with our fellow potential Kern users. Cabin Digital LLC was founded by my wife as a logical growth of another business she owns. While we are a small company with about 20 folks most of us are seniors in major corporations, I’m the CTO for a 3 billion dollar defense contractor. So while we’re small we like to think we had some really smart folks on our team and that helps when you make big decisions. For a small company buying a CNC Laser is a big decision. For Cabin Digital it would be one of our larger assets. We did our research and really came down to two choices–a Kern system or a Chinese produced system. We looked at the specs and the Kern was clearly a better system. We looked at the price and for Cabin Digital we had a really hard time justifying the significant price difference between the two systems. We did as much research as possible even looking for used Kern systems. Finally we decided that the Chinese Laser was the best option for us and then placed an order for about $25K.This is when the reality of the challenges became clear. The company sought payment via PayPal and needless to say we felt concerned dealing with global transfers of money to China. We were committed and said as a team I hope we actually get a machine–not a good feeling. About 2 weeks passed and we were contacted to arrange customs clearance. Now we were a bit surprised because our deal included shipping… Shipping yes but customs no… We then spent about two weeks finding an agent and providing all of the use papers. The Chinese company offered to declare the system “parts” we declined not desiring to commit import fraud. Sure we want to save money, sure we thought these costs were included but we’re not going to break the law. We negotiated a tailgate delivery as we didn’t have a forklift at our shop were the laser was being installed. Big mistake! They sent the system it made it across the ocean and arrived at our shop about 2 months after we paid for it. The driver backed up with his lift gate truck and said how are you going to unload this? I said lift gate right? He replied it’s too big for the lift gate…With some quick scurrying we got the tractor with forks (no forklift) and combined the lift gate with the tractor to get the crates out–so much for “free” shipping. We unloaded and got the machine in place. This was a large 1200mm x 1600mm 150W CO2 system and included the chiller and associated accessories. Wait, where is the honeycomb? Where is the rotary option? Several emails later and eventually I had to provide a copy of their email to them with those promises. That resulted in a request for me to pay additional shipping and customs–my reply no! I offered to have the machine returned at their expense and suddenly they sent the “extra” parts. Now on to machine setup…we had a space ready and quickly had the machine in place and the vents, power and air. The machine didn’t have a computer with it–you provide that but the software and software key were included so we hoped that would be easy. First we powered up the system and the laser head moved to the back right corner and when almost there sounded an alarm and shutdown. We looked and tried a restart and had the same problem. A few days and a few more emails and we had a cause–seems a proximity sensor has been tilted and needed to be bent back into place. Not good but at least it was easy to fix. The system also allowed the blowers to be controlled through switched outlets and we plugged them in and tested that–low and behold the fans power up and then stopped… Go to the back of the machine and what do you find old style push and turn buss fuses. Both blown… Replace repeat, replace repeat and decide to finally replace with two breakers. Looking inside the machine these wires for the fans are clearly undersized–not to mention that the outlets don’t have a ground pin…Our decision we’ll power and control the fans outside the system. It works and it’s easy… On to software. We have a clean XP machine and load the software following the scattered directions. All seems fine and we try to connect to the machine and get driver errors… For a minute I was transported back to the 80’s when every computer device seemed to complain and tell you to contact the vendor… A two-week session of emails and lots of trials and errors suggested that the controller or display was bad and they would send a new one… Ok wait on DHL and soon we have a controller and do the install and test… Guess what same problem… Another 2 weeks of emails and even some YouTube videos sent to the company and still no answer. Cabin Digital is an engineering company and has a few good software developers. Up to this point we doubted ourselves. Were we were doing things wrong or did we have a hardware problem? After a bit of file-by-file inspection it became clear the machine shipped with the wrong configuration files and was trying to configure incorrectly. We asked for the correct files and after a bit of “You should have that”, “We don’t”, they sent the right file. About three months and untold hours we were finally up and running. The laser was finally cutting and engraving and earning its keep. Overall it did a pretty nice job, of course we didn’t have a comparison. We were excited that the system was working and as we learned the software things settled down. We run the machine for about a year and over that time replace a lens and mirrors based on debris but again we didn’t have a reference point. About once a month the laser required an alignment that takes about 2-3 hours to get right… The mirrors have classic springs and screws but when you tighten the jam nuts the alignment changes–it was a long trial and error to get the alignment process to work across the entire table. It never cut perfectly everywhere and occasionally we would have to recut one part. That slowed us down as we couldn’t confidently cut and entire sheet or engrave a large area with consistency. Still we pressed on and in a year our laser business was growing–actually growing so well these problems were beginning to be a big pain.

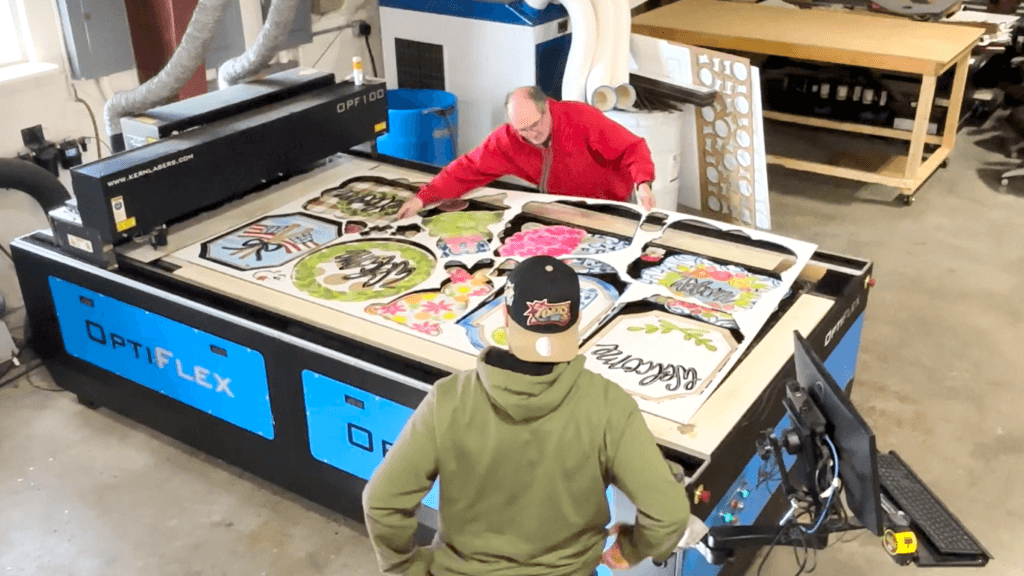

At this same time Keith from Kern called and said he had a machine we might be interested in and we had a chat. Cabin Digital had a discussion and decided it was time to move on and make the financial commitment and buy a Kern. It didn’t take long to sell the Chinese Laser and suddenly I was at Kern in training on the new machine.

First impressions–Holy Cow! The Kern folks have a great design, factory and their acts together not to mention the folks are super nice!

As I began to look and learn there are some clear MAJOR differences in the design and operation of the machine.

First the Kern uses a RF laser and hence the power and control are far better. This nice large aluminum “box” took the place of our glass tube in the Chinese laser.

Second, the Kern Laser is mounted on the moving gantry–this seemed strange but as I looked it suddenly became clear this means that only 1 mirror moves in the Kern. The Chinese laser moves 2 mirrors. That might explain the alignment challenges we had with the old machine.

Third, the entire optical path was enclosed and uses purge air–unlike the completely open Chinese design–that might explain the mirrors and lens damage.

Fourth, the Kern is clearly fully integrated, tested and functional the system and software play well together and even in training I was already seeing new and better things Cabin Digital would soon be able to do with this great machine.

So what did we learn so far? The money we saved on the Chinese laser was mostly spent in delays, and problem solving. The system is just really a large version of a non-commercial design and would never be a decent production machine. The Kern machine is a clear solid design that solves the problems we were having with the Chinese Laser system. If we had it to do over we would have started with a Kern… It’s a lesson learned and one we are sharing with you.

Rich Domikis

Managing Partner

Cabin Digital LLC