Technical Tip – Purge Gas 101

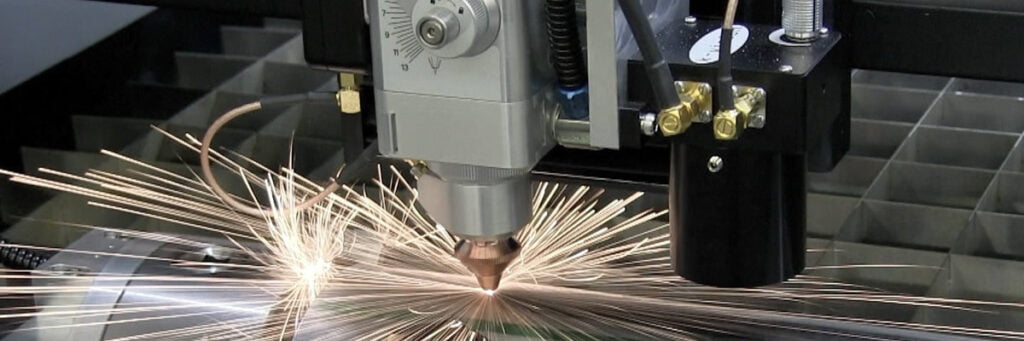

We hope this article helps you better understand the purge requirements of your laser system. With proper purge gas setup and consideration, your lasers performance and lifetime will be improved. WHEN TO PURGE Kern’s 250 watt and greater laser systems require a purge gas connection. This includes Kern’s CO2 and fiber laser systems. WHY PURGE? The purge gas serves two ultimate purposes. First, is prevents