Here are five business categories that should consider using laser-cutting machines in their production processes, as well as descriptions of the ways these machines can benefit them.

Continue readingWork Smarter, Not Harder With a Kern Laser System

KERN LASER SYSTEMS CUSTOMER TESTIMONIAL

“I found Kern Lasers, and it changed my life.”

Spider Johnson is a professional artist and a proud owner of a Kern laser system. In today’s post, I’ll be sharing a video featuring Spider’s journey through both buying a Kern laser and operating it for 15 years.

AUTOMATING MANUAL PROCESSES

It all began when Spider Johnson was looking for a way to increase production. As a professional artist whose work included hand-cutting wood with either a scroll saw or an X-Acto knife, his production capabilities were limited to how much he could manually process each day. It was around that time when Spider saw a laser demonstration at a trade show and started to wonder if a laser could be the thing to help him increase production.

“I needed to increase my production, and a laser could make identical cuts, which would allow me to make limited editions of my work.”

SHOPPING AROUND

“I checked with many different manufacturers, and called them up, asked them if they had a product that would serve my needs, my particular needs…I had spoken with Gerald Kern, and he asked me lots of questions about what I needed a laser for… he was the only one of those people to go to my website, download some of my photos, and send me laser engravings of those photos on different materials.”

This gesture turned out to be one of the reasons Spider ended up purchasing a Kern laser, but it wasn’t the only one. Spider ended up purchasing a 50W 4’x4’ laser system to support his work. His reasons for choosing a Kern include:

- Kern’s friendly customer service

- The industrial quality of the laser

- The open x- and y-axis on the table

“The most outstanding nature of a Kern laser, I think, is their customer service.”

GETTING STARTED WITH A KERN LASER SYSTEM

“When I was first unpacking the laser—this was completely new territory for me. I had no idea how to operate, much less put it together. The instruction booklet was great, but of course I had some questions. Every time I called, they were eager to assist, no matter how stupid the questions were or how long it took. And over the years, this has proved very beneficial to me. Because even after 15 years, I can call them up and no matter how long it takes, they will help me solve my problem.”

15 YEARS OF SUPPORT AND SERVICE

Although owning and operating a laser was new territory for Spider, he’s now had his system for over 15 years. Still, he can, and does, rely on Kern Laser Systems anytime he needs technical support, service or maintenance on his system.

“I had a recent need for tech support, called up and talked with both Eric and Derek. And this need, Kern over the course of 2-3 days, I would have to call and try something. No matter how long it took, they were patient, courteous, knowledgeable. And even after that long of a period of time, that kind of tech support, here in the good old USA is not easy to find.”

SPIDER’S RECOMMENDATION

“I would highly recommend Kern lasers over any other laser product for all those reasons. I think they’re the best company on the market. I think they care about what they do. The customer service is great. The products are very well made. The only problem I’ve had in 15 years was a control card that had some issues. I sent it in overnight for repairs, they sent it back the next day. It cost me $500. I can’t think of any other product, including automobiles, that I’ve had for 15 years, where the maintenance has only been $500. Kern lasers, they’re the best.”

Thank you, Spider, for sharing your experience with Kern lasers and recommending our systems to others!

Maximize Your Production Time With a Kern Laser System

For small business owners and entrepreneurs, it can feel like long days and late nights spent working is just part of the gig. But sometimes, getting more done doesn’t have to mean working more time. In fact, by investing in the right equipment, it’s possible to improve manufacturing efficiency and give yourself some much needed time to breathe.

HOW TO IMPROVE MANUFACTURING EFFICIENCY

While it’s true there are only so many hours in the day, there are ways to get more done in the time available. For many, increasing manufacturing efficiency is something that sounds good but seems impossible. After all, if it’s all hands on deck, what else can be done?

Here at Kern Laser Systems, we’ve seen countless individuals improve manufacturing efficiency by using a laser system.

AUTOMATE MANUAL PROCESSES

Automating manual processes is a great way to increase manufacturing efficiency. Take, for instance, cutting. If your trade or production efforts include manually cutting materials like aluminum, fabric, foam, leather, wood or some other material, imagine how things would change if that cutting was automated and accomplished using a laser cutter? For many, a switch like this would be revolutionary for their production numbers.

For example, say you’re a manufacturer of engraved wooden coasters. At first you started out as a small etsy shop, doing the engravings with a CNC, after a few months your demand has reached a level where you now have multiple back-orders, a wait-list, and are losing customers due to not being able to meet the demand fast enough.

You are now overwhelmed with work and unable to catch-back up which not only takes a toll on your business, but also on you as you spend more and more time engraving coasters to try to meet the demand.

Now imagine if you purchased a laser to do the engraving for you.

You could do multiple coasters at-once with only a small amount of finishing after the laser was done. You would be more efficient, enabling you to meet, and even exceed, demand. This would allow you to continue to grow your business, and allow for free-time to spend with family and friends.

The best part, a laser system increases efficiency and productivity immediately.

DOUBLE YOUR PRODUCTION CAPABILITIES

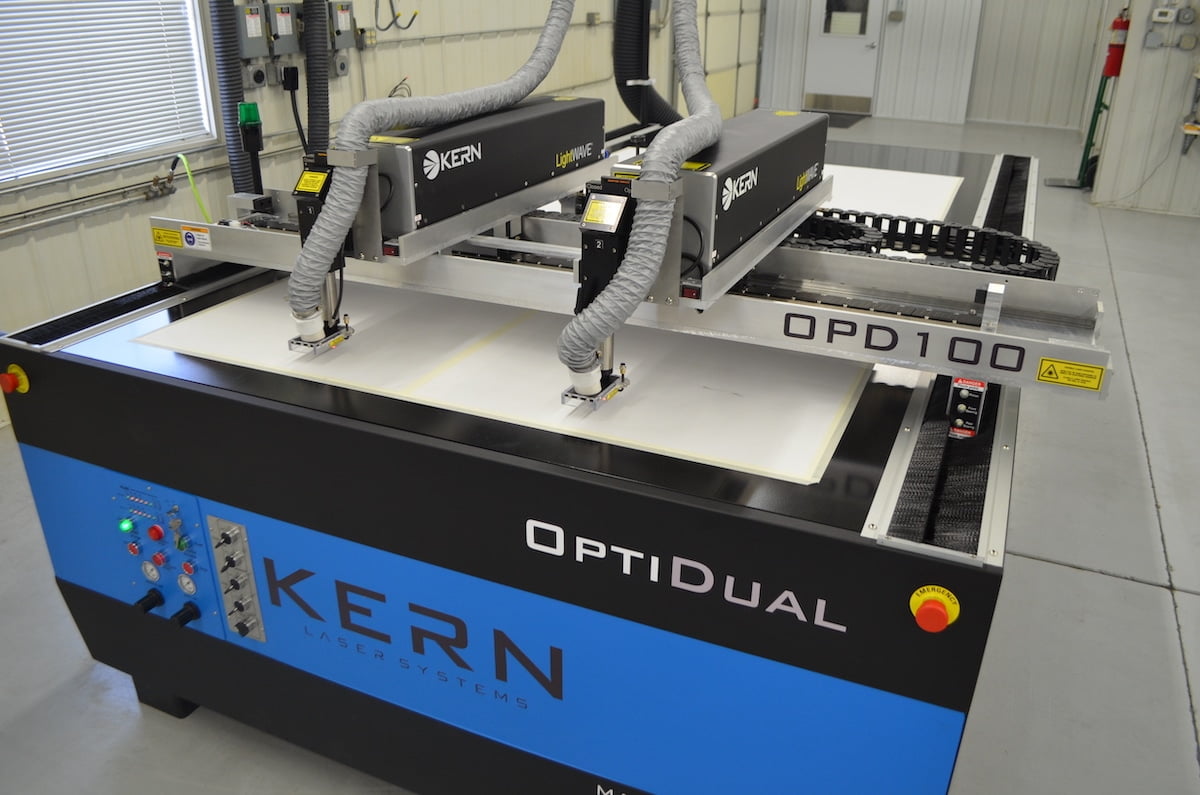

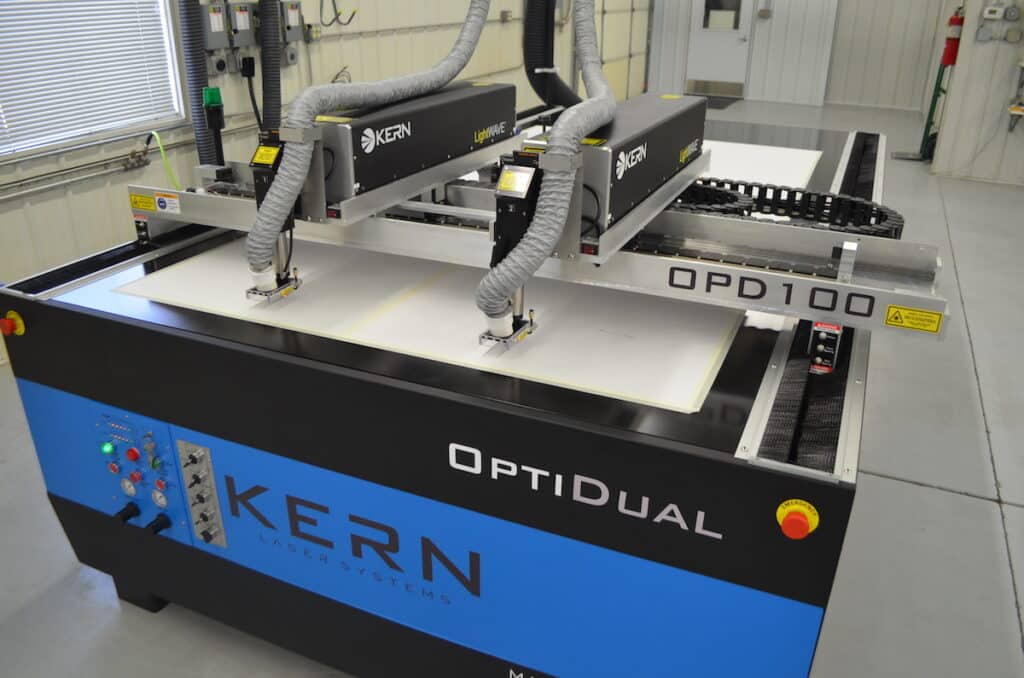

For manufacturers looking to increase production efforts, another option is to invest in a dual-head production laser cutter like the OptiDual., Dual-head production lasers make it possible to increase production yield by doubling down on laser processing. Here’s a quick video of the OptiDual in action:

As you can see, the OptiDual operates with two nozzles mounted on a single gantry. They work side-by-side, cutting the exact same shapes and patterns. For industrial-scale production, the OptiDual is an excellent option.

ACHIEVE MANUFACTURING EFFICIENCY WITH KERN LASER SYSTEMS

A Kern laser system provides owners and operators with the capabilities to increase manufacturing efficiencies, allowing you to accomplish more in less time.

Try out the laser fit tool to help determine which Kern laser system fits with your laser processing needs.

Who Uses Kern Laser Systems? A Look at Industries We Serve.

Kern laser systems are used within a wide range of industries. Here’s a list of the industries we serve, along with some examples of the materials and products lasers processed for these industries.

AEROSPACE

Within the aerospace industry, laser cutting is heavily relied on. Parts and components that go on to support aircrafts, military defense and space exploration rely on the accuracy, cleanliness and precision of laser cutting. Companies like Boeing and Dassault Falcon rely on the laser-cut precision of Kern lasers.

AUTOMOTIVE

Fiber lasers and properly fitted CO2 lasers are used within the automotive industry to cut, engrave and mark. Here’s a look at some laser-cut automotive details.

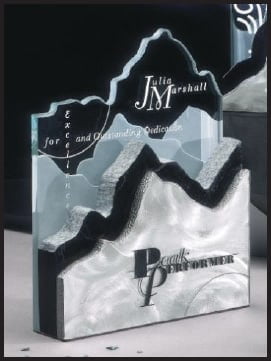

AWARDS AND TROPHIES

Laser cutting and engraving brings more unique elements to today’s awards and trophies. Commonly cut from acrylic, metal or wood, laser-cut awards and trophies are popular in corporate settings, athletic competitions and the arts.

With lasers, etching text and images onto the award looks professional and lasts a lifetime. Here are some examples of awards made with laser processing:

FOAM FABRICATION

Foam fabrication with laser systems yields much greater precision and much less waste than other methods like saw cutting or searing it with a hot rod. Foam box shadow tooling is perhaps one of the most popular forms of laser-cutting for foam. It requires only a low-power laser and yields precise results.

For instance, cutting three-inch foam pairs perfectly with a 150 watt laser. If operators use too high of a wattage with foam, they run the risk of burning the material.

HEADSTONES AND MEMORIALS

Laser cutting and engraving for memorials and headstones makes efficient work out of adding images, landscapes and inscriptions to natural stone.

Businesses that provide memorial services, like funeral homes, cremation providers and pet memorialists all rely on laser cut precision to help create one-of-a-kind memorials for loved ones.

HEALTHCARE AND MEDICAL

The use of laser cutting, marking and engraving is widely utilized within the medical industry. Laser cutting lends itself to creating medical devices, especially as devices and products shrink in size and grow in intricacy. Laser systems provide the precision and speed required for medical device production.

For instance, in the early months of 2020, the need for medial PPE surged. And in response, laser owners and operators from every area of industry pivoted their production efforts to meet this demand, producing face shields, face masks and other protective barriers.

JOB SHOPS

A versatile laser system is right at home in a job shop. Job shops are just that, shops that take on jobs of all shapes and sizes. Kern laser systems, with their ability to process a wide variety of materials with precision, can help job shops be even more successful.

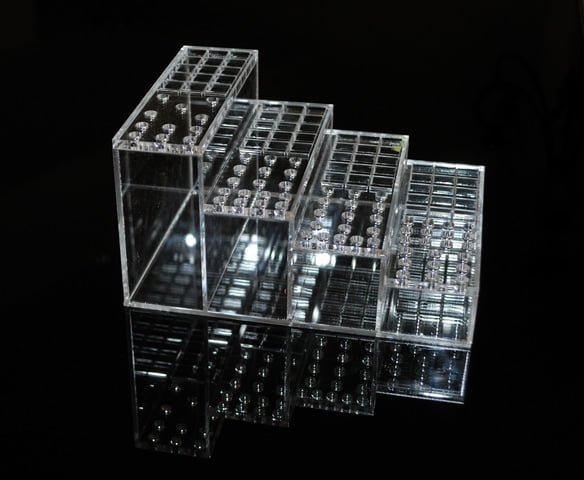

POINT-OF-PURCHASE DISPLAYS

With laser processing, companies can create custom displays for their products. For example, makeup companies with custom displays for their products will have the name of each product or the color number etched right into the display where the product is held.

SIGNAGE

Laser systems provide an unmatched level of versatility within the signage industry. Laser cut and engraved acrylic, wood, plastic and metal materials are used to create signage. Signage is used in all areas of business, from local mom and pop shops to medical facilities. With laser engraving, signage can be etched to include words, room numbers, ADA lettering and more.

TEXTILES

Laser-cut textiles are becoming more and more popular. Lasers do an excellent job cutting a wide variety of textile materials, from cotton and polyester to silk and nylon. Unlike with scissors or other cutting methods, laser cutters do not leave rough edges behind or cause fraying.

WOODWORKING

Woodworking and laser processing make a perfect pair. Lots of wood materials respond well to laser cutting and engraving, creating beautiful results. Here’s a look at some wood products created with Kern laser systems:

This was a brief look into the ways laser systems are used in a variety of industries. Please know, this is not an exhaustive list. We work with customers from just about every industry imaginable to help them apply laser processing to support and strengthen their business.

Top 5 Tips For Laser Cutting Thick Acrylic

When laser cutting an acrylic sheet, the last thing you want to see is an uneven cutting edge or surface — or even worse, your cutting kerf turning white while processing colored acrylic. Armed with a few quick tips, anyone can increase their skills in cutting thick acrylic with a laser cutter.

When laser cutting an acrylic sheet, the last thing you want to see is an uneven cutting edge or surface — or even worse, your cutting kerf turning white while processing colored acrylic. Armed with a few quick tips, anyone can increase their skills in cutting thick acrylic with a laser cutter.

Acrylic is one of the top materials chosen for laser processing. That’s partly because lasers can create such a stunning result. Other technologies, like routers or saws typically leave behind hazy or milky edge colors, requiring a secondary process to achieve flame polishing.

But that’s not the case with lasers. If it’s done properly, that glossy, flame-polished edge is achievable through a single process.

1. CHECK YOUR WATTAGE

For laser cutting thick acrylic, you’ll need a high enough wattage to get the job done. Thinner sheets, like ⅛ inch acrylic cut beautifully on 150w or 200W, but if you’re looking to cut one inch acrylic, you’re going to want a 250w or 400W laser.

2. REDUCE AIR ASSIST

Air assist will prevent your laser cutter from achieving a fire-polished edge and instead result in a frosted white effect. When air assist is reduced (we recommend using a wide nozzle to dissipate the air pressure) it lessens the chance to have a ghosting effect on the acrylic.

3. CHECK YOUR LENS

While most operators know they need a very low air pressure to achieve that fire-polished edge, they might not be aware of how dirty that can make their lens. A dirty lens is going to give operators a whole host of problems, from poor focusing to reduced laser power. Prevent these possible downsides by checking your lens daily or at least every other day if you’re cutting a fire-polished edge into acrylic.

4. FOCUS INTO THE MATERIAL

To achieve a more consistent beam width, adjust your focus toward the middle of the acrylic sheet. If the focus is on the top of a thick sheet, the laser will be out of focus by the time it reaches the bottom.

5. ADJUST YOUR FOCAL LENGTH

To get a laser to cut nicely through thick acrylic, it’s helpful to adjust your focal length so that the laser energy is concentrated. For instance, if you want to cut a half inch or one inch piece of acrylic, a longer focal lens is going to spread out the focus distance and give you a straighter cut. It will make the beam a little wider, but will prevent a slanted or uneven edge.

When you’re investing in laser processing, you deserve to see picture-perfect laser precision, but the reality doesn’t always live up to those expectations. If you’re interested in cutting thick acrylic, we can match you up with the Kern Laser System to meet your needs.

If you’re interested in seeing how Kern lasers cut acrylic, request a free sample kit.