6 Industrial Laser Engraving FAQs, Answered

In this blog, we dispel some common myths and misconceptions about lasers, specifically about laser-cutting machines like those we manufacture and sell.

In this blog, we dispel some common myths and misconceptions about lasers, specifically about laser-cutting machines like those we manufacture and sell.

Many of our customers, and those in the industrial laser industry, know Kern as a reputable US manufacturer of laser cutting and engraving systems. Kern has been manufacturing laser systems since the early 90’s and has thousands of systems in the field working on a wide spectrum of applications. Up until 2012 Kern partnered with various vendors to supply the “heart” of our laser system,

A good laser cutting or engraving system is a versatile machine that will allow a knowledgeable operator to produce a high-quality product using a variety of materials. That being said, a single laser may not be the appropriate choice for every application. You don’t necessarily need a high-powered CO2 laser system if you’re only using it to cut sheets of foam for furniture padding. Depending

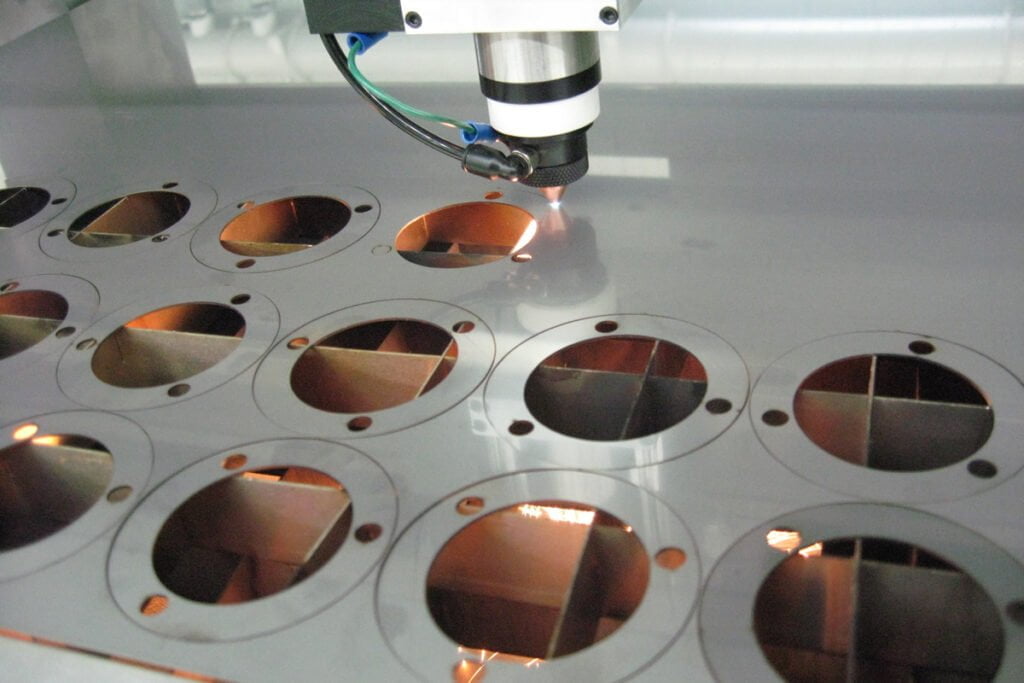

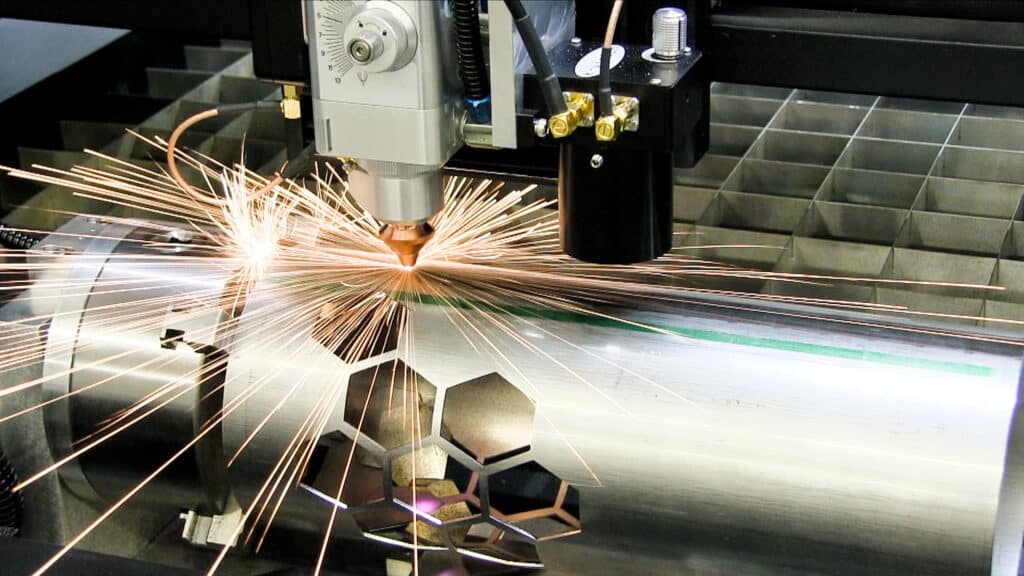

Sheet metal cutting lasers are complex precision tools. When they are working at their best, they should be consistent: doing the same job to the same standard of quality, day-to-day. However, some components on a laser system are designed to be replaced, and failure to keep up regular maintenance can lead to a lower-quality product. In addition, a complex system like a laser cutter presents

If you are looking into acquiring a laser cutting machine for your business or other projects, you may be feeling overwhelmed at the many types of lasers, levels of specifications, and price points out there today. And you may wonder what kind of under-the-hood differences there are between, for example, a laser system manufactured overseas and a U.S.-built laser system like those we offer at

To the layperson, the word “laser” can bring to mind some exciting, but perhaps not altogether comforting images out of popular culture: lightsabers and other sci-fi weapons from Star Wars, lasers used for security or intimidation in spy thrillers, laser-guided missiles, and submarines. And of course, lasers bring a more modest set of real risk factors associated with their improper use or malfunction—eye injuries, burns,

We are happy to announce the release of new versions of our FiberCELL and LaserCELL laser systems with 52” x 100” laser tables. These larger format configurations will be available in addition to the existing 52” x 50” versions of each model. 52” x 100” is our most popular size for laser systems, including our entry-level EcoFlex and flagship Optiflex systems. This size allows for

The story of laser manufacturing in 2023 and beyond looks to be one of continued growth in spite of lingering economic headwinds from pandemic recovery, supply chain challenges, and the general economic volatility of recent years. What trends and changes in the laser manufacturing industry are likely in 2023? The fiber laser industry is predicted to grow by approximately 880 million dollars between 2022 and

We are updating the wattage of our mid-range lasers, replacing the KT250 and KT400 models, which are rated at 250 and 400 watts respectively, with the new 300-watt KT300 and 500-watt KT500. About the Model Upgrade The KT250 and KT400 model lasers were introduced in 2016, and since that time the teams at Kern Laser Systems and Kern Technologies have continued to advance our lasers’

An important part of any laser system that often gets overlooked is the vacuum blower system. An adequate vacuum system is essential to remove the fumes and small debris that are created during the laser cutting and engraving process. This blog will highlight Kern’s complete blower system, optional upgrades and dives into tips and tricks for more efficient fume removal. Vacuum blowers are included as

Please enjoy this article written by Scott Snell, Technical Sales Manager, with Purex. The article is a great recap of fume extraction and how it relates to laser systems. WHAT IS FUME EXTRACTION? Fume Extraction is an engineered control method to capture fumes from processes that generate them… When we talk about Fume Extraction in the realm of Laser operations, we are typically talking about

MDF (Medium Density Fiberboard) is a strong, engineered material made of wood fibers, wax, and resin. The ability to laser cut profiles and engrave deep numbers and logos has much money-making potential in the crafting, signage, interior design, and furniture industries. Laser cutting is an easy way to process shapes with minimal scrap material. A common problem I see from customers who are trying to