From Custom Cuts to Big Wins: Diverse Woodworking’s Success Story

Established in 2007 in his garage, Randy Elliott, President and CEO of Diverse Woodworking, LLC has grown into a leading manufacturer of MDF cutouts, serving a variety of industries with high-quality craftsmanship and precision. Located in southern Indiana, the company has carved out a strong niche in the “Paint & Sip” industry, supplying craft cutouts to paint parties, craft stores and other businesses of a similar nature. Large format UV printing has allowed Randy and his team to work with artists to mass-produce their work and designs to be sold in retailers nationwide. Over time, Diverse Woodworking expanded into the printing world, producing printed acrylic and wood MDF items for gift stores and other retail settings. Fit with a 17,000sq. ft. building, Diverse Woodworking has worked with several high-profile companies such as Coca-Cola, Disney, Weber Group, Universal Studios, and even the Kennedy Space Center.

The Challenge

As demand for Diverse Woodworking’s products grew, Randy recognized a pressing need to enhance production capabilities. Initially, cutting small, intricate items was a challenge, with the company using routers for items as small as 6 inches. However, the increasing need for precision and efficiency required a more advanced solution.

The company made its first major investment in automation by purchasing a CNC machine in 2012. After their appearance at the 2015 Dallas Market Gift Show, business accelerated and landed them a catalog of more than 1500 SKUs. Diverse Woodworking needed to keep up with the evolving needs of their business. With a rapidly growing business, Randy sought out to find a more precise and efficient cutting solution.

Customer Details

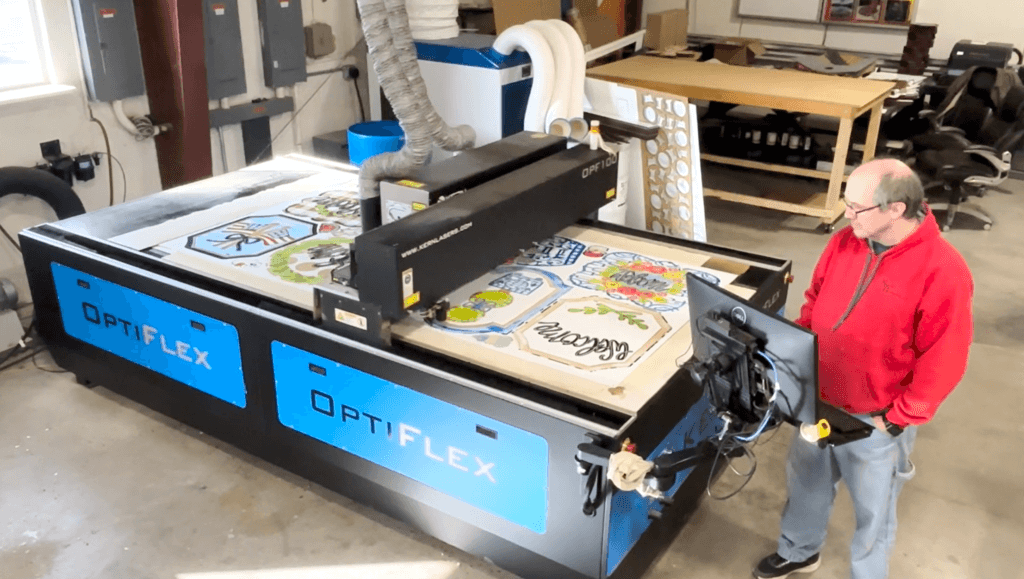

Model: OptiFlex

Wattage: 500W

Bed Size: 52″ x 100″

Industry: MDF cutouts, personalized products

Location: Georgetown, IN

The Solution

Randy first encountered Kern Laser Systems at the International Woodworking Fair (IWF) in 2016. From the start, he was impressed by the company’s commitment to customer service, training, and support. In 2018, Diverse Woodworking purchased its first Kern laser, marking a substantial shift in its production process. The transition allowed the company to efficiently cut intricate designs and improve overall workflow.

As demand continued to grow, the company added more Kern laser systems over the years. Continuing the trend with the OptiFlex 52” x 100”, 500W with k-vision, Randy and his team added three more machines, with the latest being delivered in February 2025. The adoption of Kern laser technology enabled Diverse Woodworking to integrate a print-and-cut workflow, where designs are printed, on either MDF or Acrylic, and then cut out using registration marks.

The Impact

With Kern lasers, Diverse Woodworking has successfully transitioned into new product categories, including cutouts for stained glass inserts and a variety of printed items for gift stores. The precision and reliability of the lasers have significantly improved the company’s ability to handle intricate designs, making

it easier to fulfill customer orders quickly and accurately. With 100% satisfaction guaranteed and quick turn-around times, each of their products are made in the USA. Randy and his team can print up to 16,000sq. ft. of material in a single 8-hour shift.

Beyond the technology itself, the support from Kern has played a crucial role in Randy’s decision to continue investing in their machines. “You all treat me good and I’m super happy,” Randy shared. “That’s what makes me keep coming back. The training, the support—other companies often make you wait and even charge you for support. Minimal downtime is very important for us because this is how we make our money. We use our machines every single day. If my machines aren’t running, we’re not making any money.” This level of customer service became a defining factor in Diverse Woodworking’s continued partnership with Kern. In contrast, a previous experience with another company resulted in a six-day wait for tech support on a software issue, something that was unacceptable for a business reliant on constant production.

The Outcome

Diverse Woodworking’s strategic investment in Kern Laser Systems has not only expanded its capabilities but also ensured that the company remains at the forefront of the MDF cutout and print-and-cut industry, while also having the ability to print and cut wood, metal, plastics, composites, foam, fabric and vinyl. The combination of cutting-edge laser technology and exceptional customer support has provided Randy and his team with the tools necessary to continue growing and evolving in a competitive market.

For Diverse Woodworking, the partnership with Kern is more than just machinery. It’s about reliability, efficiency, and a trusted relationship that keeps the business moving forward.