Play Video

Metal Cutting Laser System

Sheet Metal Laser Cutter

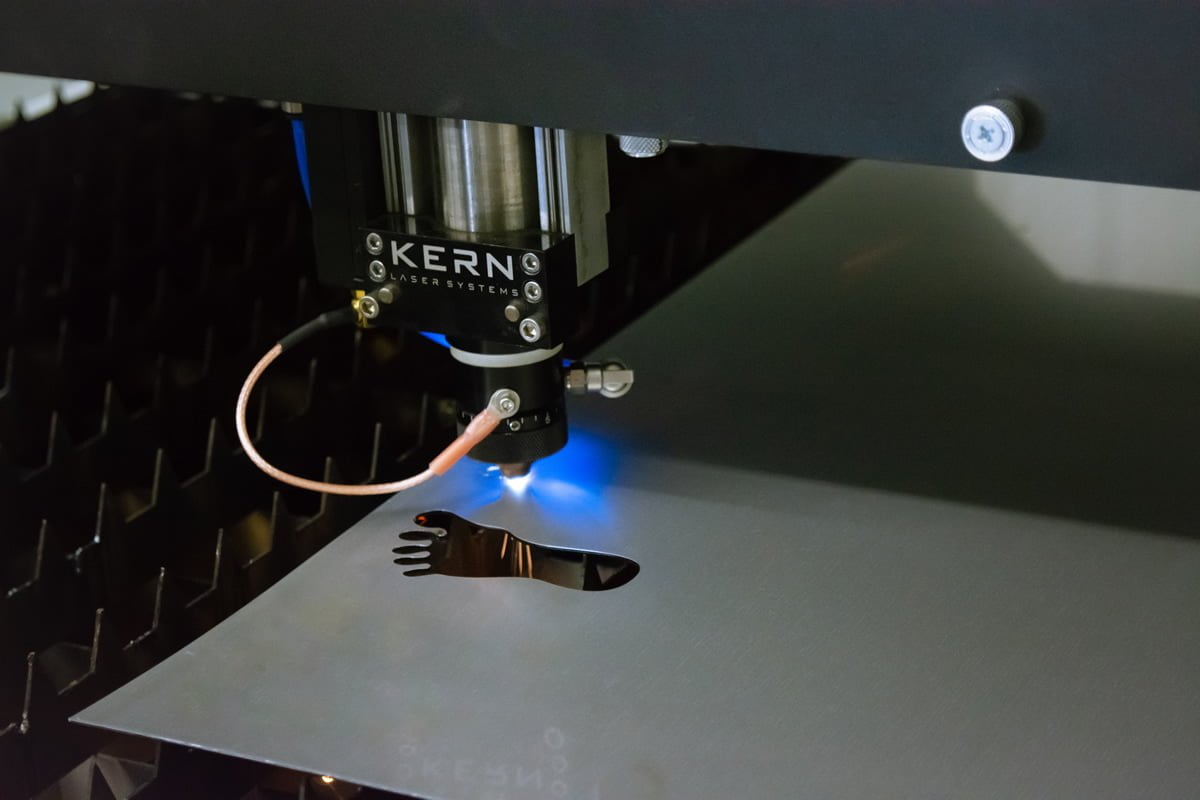

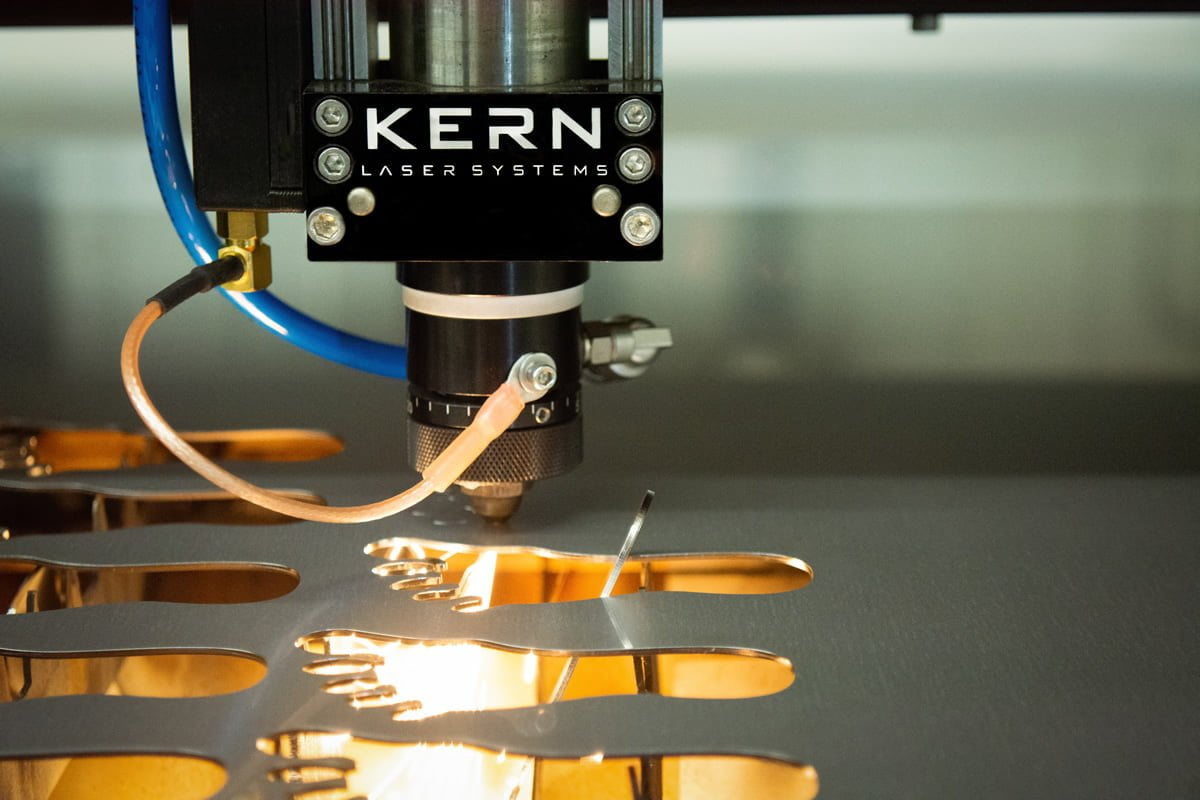

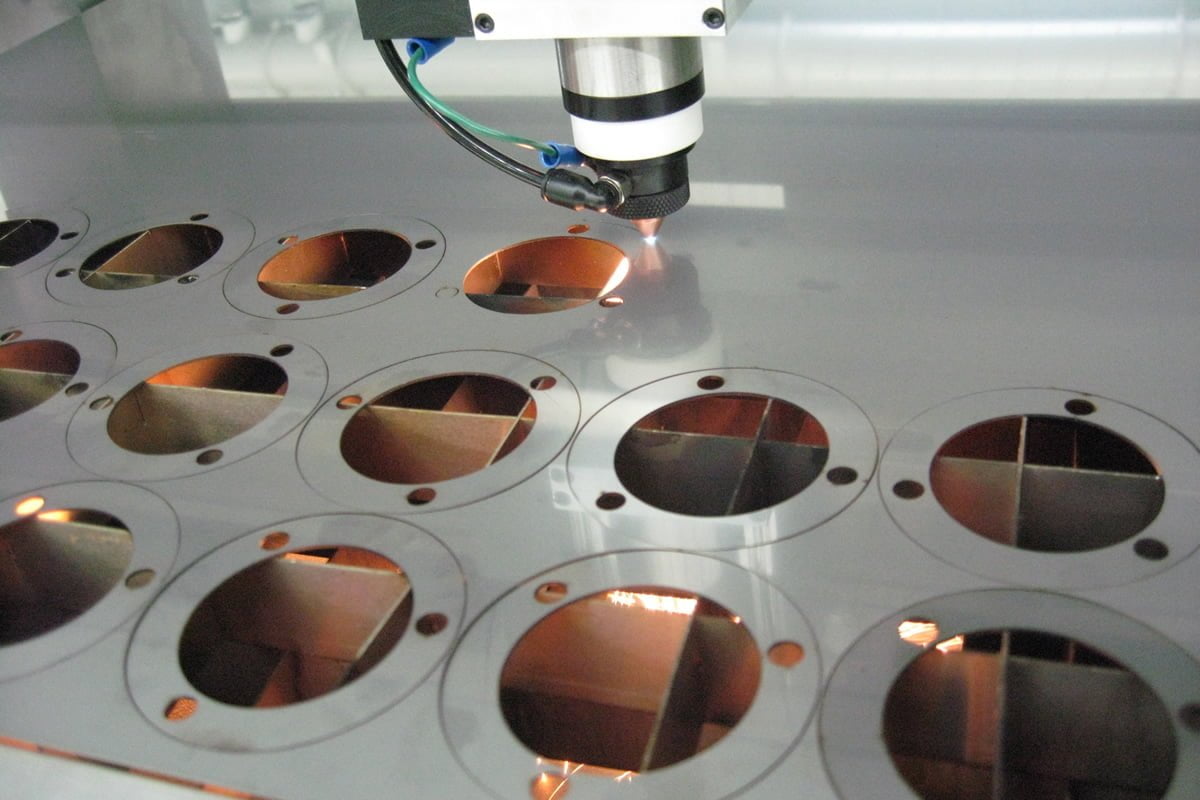

Kern’s laser systems can be equipped with innovative metal cutting technology. The metal cutting option allows for accurate cutting of sheet metal such as stainless steel, mild steel, aluminum, copper and brass.

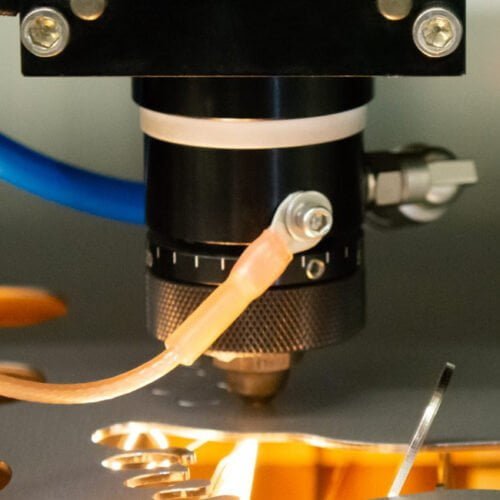

An Automatic Focusing Height Follower, developed by Kern Laser Systems, is one of the key elements for optimal metal cutting. A cutting nozzle is controlled by a capacitance sensor and z-axis motor. The gap between the metal being cut and the cutting nozzle is adjusted until the desired beam focus is obtained. During the cutting process, the height follower tracks the metal surface and adjust the nozzle position maintaining a constant focus point.

An Automatic Focusing Height Follower, developed by Kern Laser Systems, is one of the key elements for optimal metal cutting. A cutting nozzle is controlled by a capacitance sensor and z-axis motor. The gap between the metal being cut and the cutting nozzle is adjusted until the desired beam focus is obtained. During the cutting process, the height follower tracks the metal surface and adjust the nozzle position maintaining a constant focus point.

A protective cover lens is installed within the lens assembly. These lenses are a low cost, sacrificial optic which help to protect the focusing lenses from reflected laser energy, dust and debris. These cover lenses are referred to as a K-Lens on our CO2 machines and F-Lens on our fiber systems.

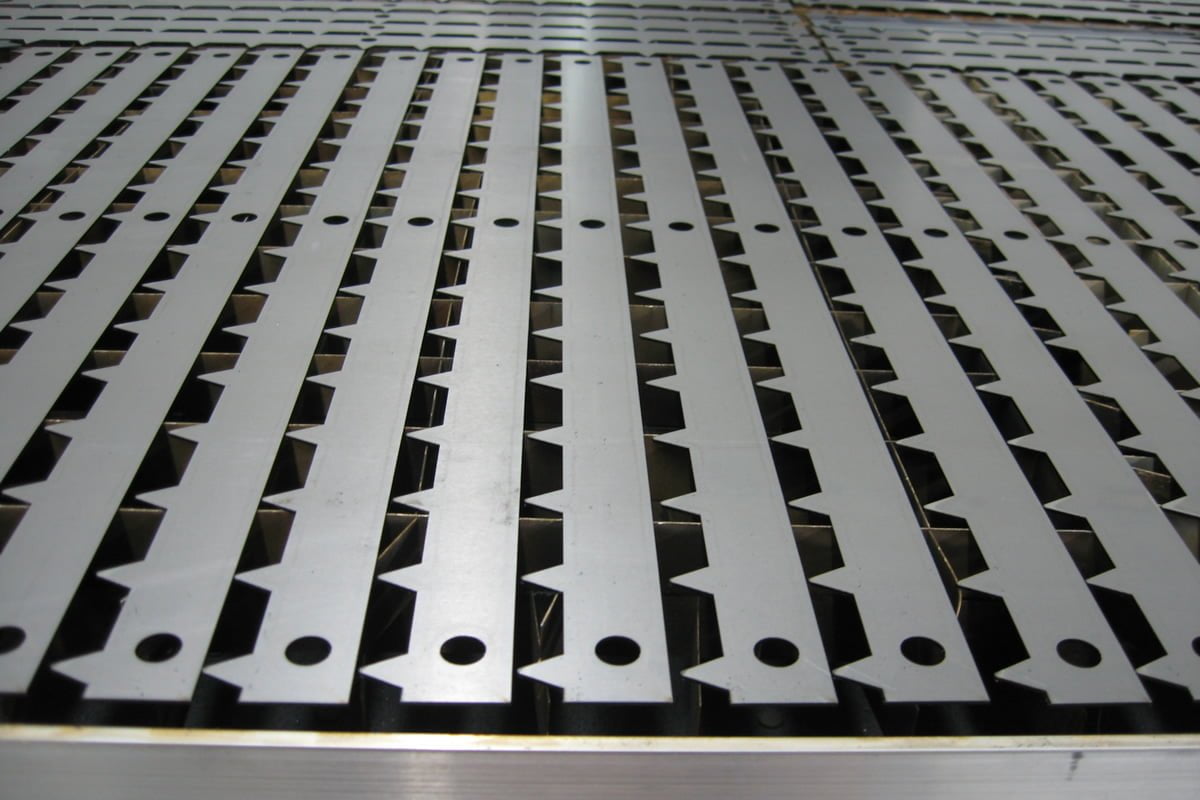

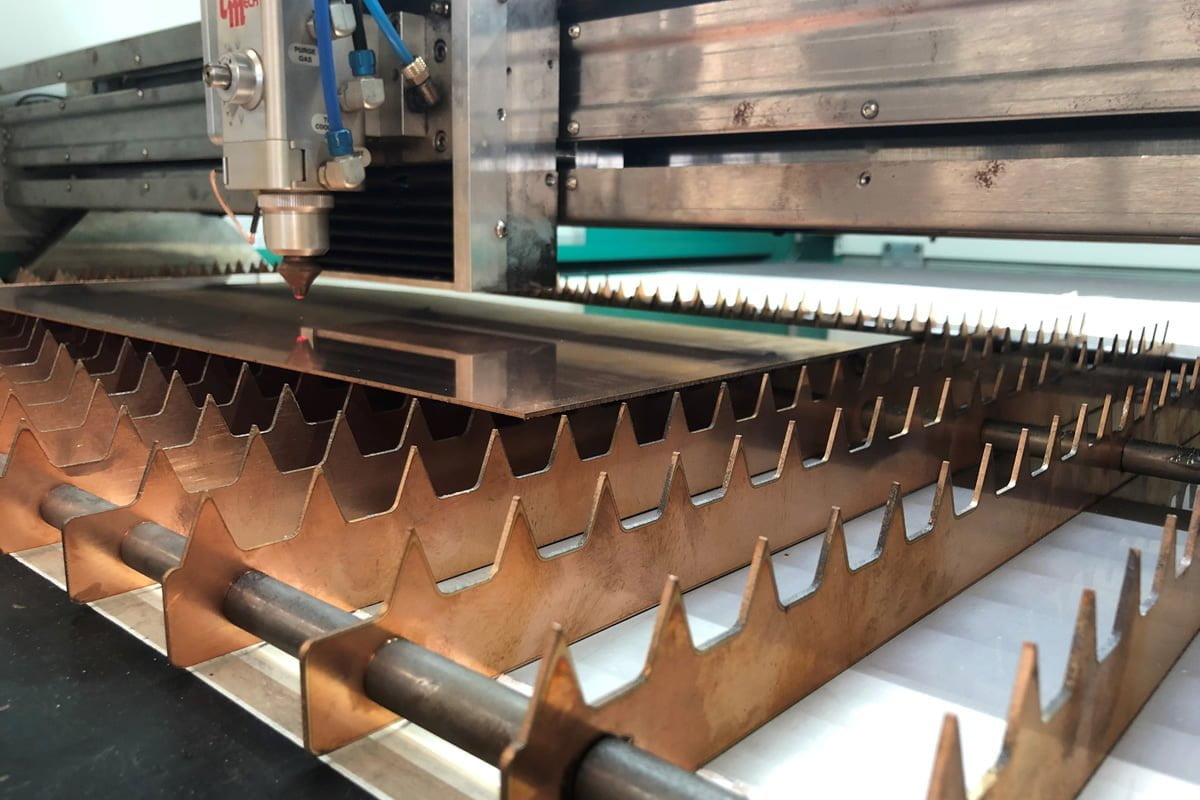

The metal cutting table is constructed of durable steel grid work which minimizes the surface contact with the bottom of the sheet metal. A CAD cut file for the individual slats is saved on the computer system allowing for operators to cut replacement slats when needed.

Both fiber and CO2 lasers can effectively cut metal. To learn more about their differences, please review this blog post: What is the difference between CO2 and fiber lasers?

LASER SOFTWARE

Advanced metal cutting features in the KCAM Laser Software give users complete control of the metal cutting process. Laser pierce delay is available ensuring the laser pierces through the metal before the motion of the cut begins. The nozzle air pressure can be set independently for the laser dwell, normal laser cutting and jog between parts. The laser’s modulation frequency can be adjusted between 500 – 50,000 Hz to achieve a dross free cut which eliminates the need for a secondary deburring process.

Striker CNC Software is an optional package which will increase productivity with capabilities such as nesting of parts and tabbing cut profiles.

ADVANCED FEATURES

What makes a metal cutting machine is more than just a powerful laser resonator. The mechanics and software have been designed specifically for cutting metal. Here are a few features that set us apart from the competition:

Programmable Air

Programmable air assist allows three gas types to be connected to the laser system simultaneously. The gas type needed for each job is set in the KCAM software, eliminating frequent handling of gas tanks and lines.

Pierce Control

Before you can start cutting metal the laser beam must pierce through the sheet. KCAM has multiple pierce parameters allowing users to set the power, dwell time, gas type, gas pressure and focus gap. All of this control allows for small and efficient pierces prolonging optic lifetime.

Fine Adjustments

Metal cutting can be a delicate process, especially when cutting very thin and thick sheets. Our KCAM laser software is able to adjust the power and speed of lead-ins and corners, allowing for consistent cut quality throughout large detailed files.

MILD STEEL / COLD ROLLED STEEL

High powered fiber lasers (1-3kW) and CO2 lasers ranging from 150-650 watts are exceptionally well-suited for cutting mild steel, a task where they excel due to a blend of power and precision. At this power range, the laser is capable of producing a concentrated beam that can easily melt and cut through mild steel, which is known for its good balance of strength and ductility. The versatility of these lasers allows for a wide range of thicknesses to be cut, with the higher end of the power spectrum handling thicker steel with ease. This range also ensures a cleaner cut with minimal kerf and smoother edges, which is crucial in precision applications. Furthermore, the efficiency and speed of these lasers at these power levels make them cost-effective and time-efficient, especially in industrial settings where both quality and quantity are essential. Their ability to maintain a consistent and controlled beam also reduces material wastage and enhances the overall quality of the cut, making them an ideal choice for a variety of mild steel cutting applications. Manufacturing of electrical panel enclosures is a classic application our laser systems are used for.

Starting with Kern’s CO2 lasers of 150 to 650 watts, mild steel can be cut at varying thicknesses up to .250″. Fiber lasers are available with up to 3kW’s of power and will process mild steel as thick as 1/2″.

STAINLESS STEEL

Kern’s CO2 and fiber laser systems can be equipped with innovative metal cutting technology. The metal cutting option allows for accurate cutting of stainless steel, leaving a clean, dross free edge. Stainless steel up to .090″ can be processed with Kern’s largest 650W CO2 laser. For thicker applications, Kern’s FiberCELL is best utilized with cutting capabilities of up to 1/4″ utilizing a 3kW laser.

Kern’s CO2 laser systems are able to etch directly onto the metal surface or leave a durable mark with the assistance of a marking spray such as Cermark.

COMMON USES

Signage

Control Panels

Architecture

Custom Car Parts

Aerospace Parts

Stainless Steel Cut Letters

Tags and Labels

ALUMINUM

Laser cutting aluminum requires a powerful and precise approach, and typically, a 300W CO2 laser is considered the minimum power level sold for effectively cutting this metal. However, a majority of our aluminum processing customers are running 500W or greater lasers.

Many aluminum nameplate manufacturers are running 500W laser systems to cut thin gauge aluminum tags and labels with great success. CO2 lasers are generally more effective than fiber lasers for cutting aluminum labels with an adhesive backing because of their longer wavelength, which is less absorbed by the metal and more effectively interacts with the adhesive layer. This allows the CO2 laser to cleanly cut through both the aluminum and the adhesive without excessive damage to the material. Moreover, the CO2 laser’s beam quality and precise control enable it to delicately handle the layered structure of these labels, ensuring a cleaner edge and reduced risk of burning or warping the aluminum or adhesive.

Fiber lasers are also a great solution for cutting aluminum due to their shorter wavelength, which allows for a more focused and intense beam, leading to cleaner and more precise cuts. Lasers from 1kW to 3kW are available on the FiberCELL platform.

Marking aluminum with a Kern laser system is also possible. A laser marking spray is used to leave a dark, durable mark on the surface of the metal. Cermark and Thermark are two laser marking sprays used on metal.

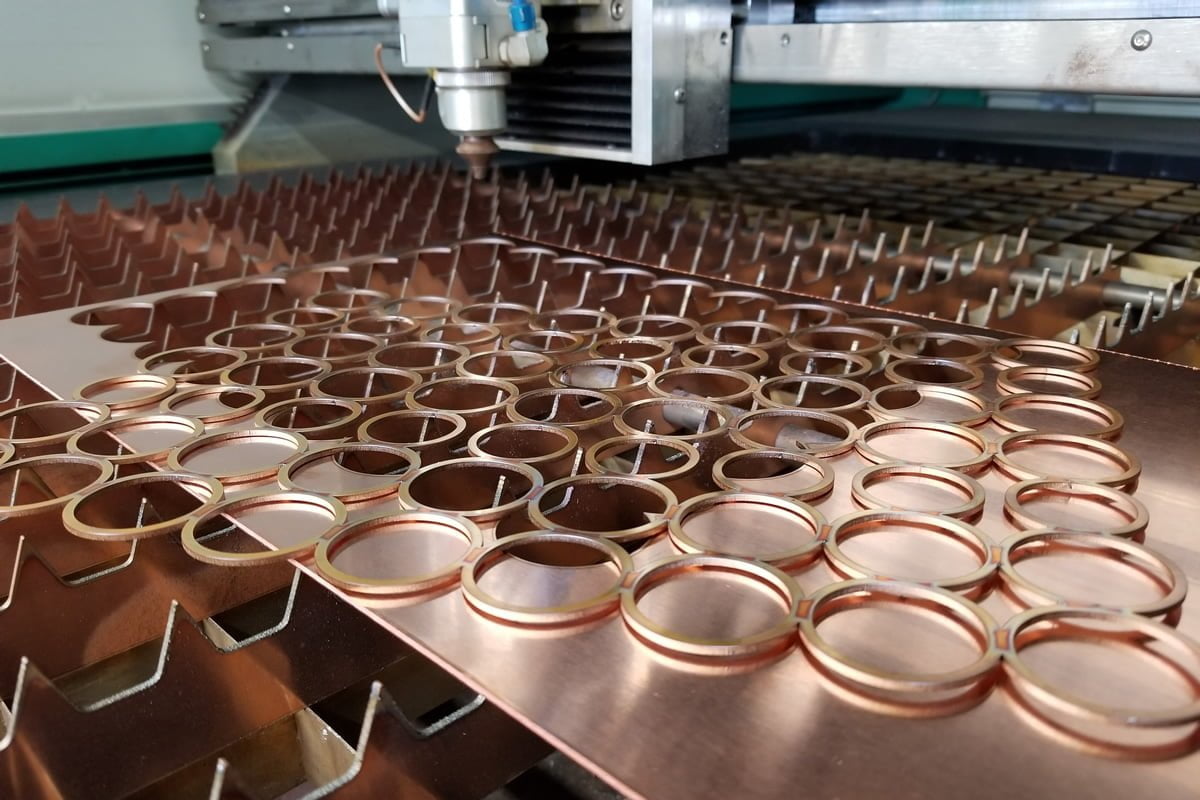

COPPER

Fiber lasers are highly effective at cutting copper due to their shorter wavelength, which is more readily absorbed by the reflective surface of copper, allowing for efficient and precise cutting. Their high intensity and focused beam enable cleaner cuts with minimal kerf width, making them ideal for intricate designs and fine details in copper work. Additionally, fiber lasers offer better energy efficiency and faster cutting speeds compared to other laser types when working with conductive materials like copper.

COMMON USES

Jewelry

Architectural Panels

Electrical Components

Stills

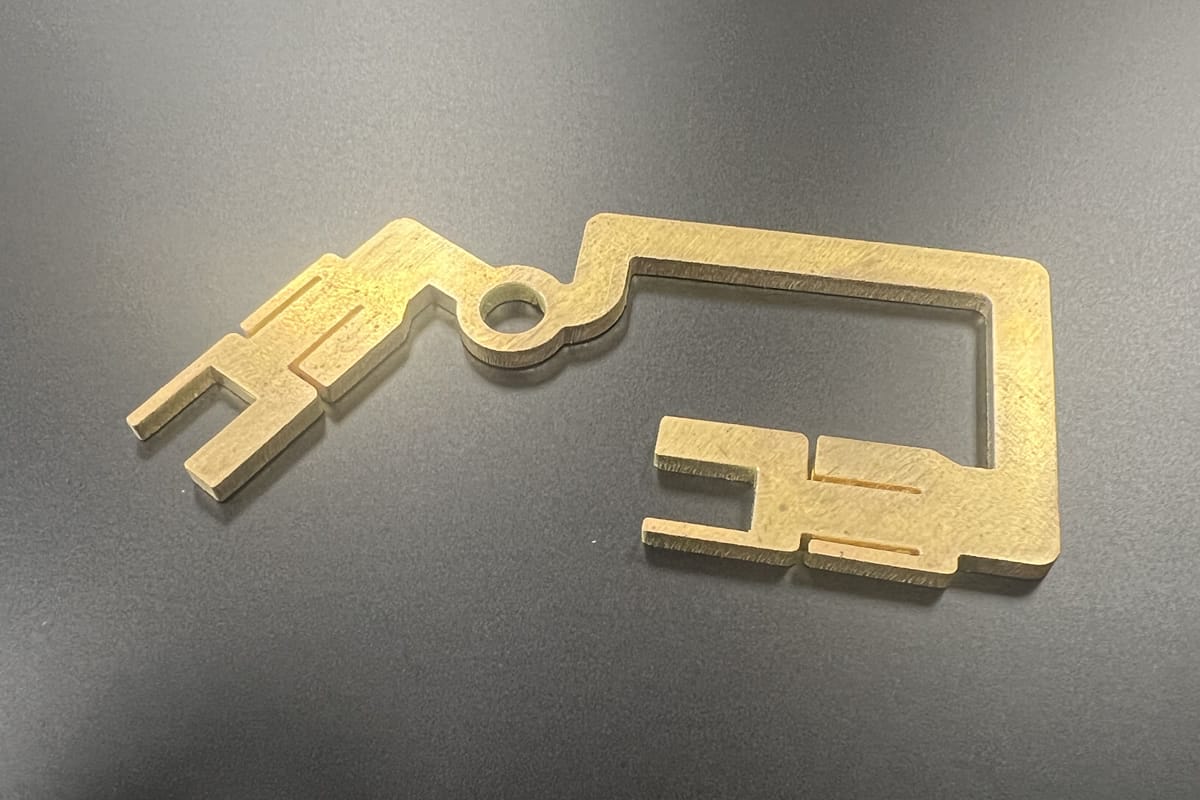

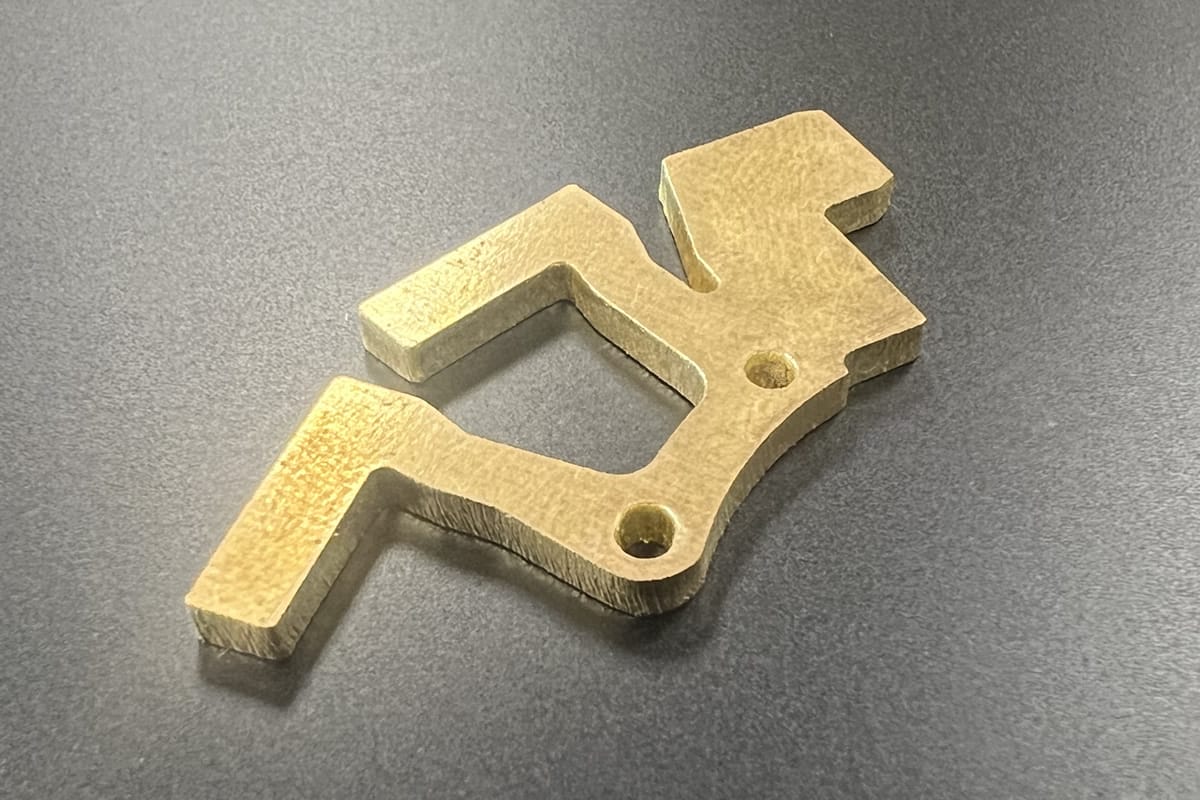

BRASS

Brass is an alloy consisting of zinc and copper. Laser cutting brass with a CO2 laser often requires careful power and speed adjustments due to brass’s reflective nature, which can pose a challenge to this laser type. On the other hand, a fiber laser, with its high intensity and shorter wavelength, is more efficient and precise for cutting brass, making it a preferable choice for intricate designs. Laser systems are capable of cutting sheets of brass to a high yield, reducing material waste and providing optimal sheet usage. Laser-processing brass results in clean cutting with an air assist, which greatly reduces or eliminates dross.

CO2 lasers below 500 watts have a difficult time cutting this reflective metal. Kern’s 500 and 650 watt metal cutting system can cut most brass alloys up to .040″ and .048″, respectively. The FiberCELL 3kW system can cut up to .1875″ brass.

COMMON USES

Architectural Panels

Aerospace Applications

Jewelry Making

Arts and Crafts

Musical Instruments

Electronic Components

TITANIUM

Titanium has a low density and is a strong lustrous, corrosion-resistant metal. This “space age metal” is used in a variety of industries and is cut with these machines. A dark, consistent etch can be applied to the surface of this metal by using a marking spray or oxygen assist gas.