Laser Engraving System

Laser Engraver Guide

Laser engraving is quickly becoming an industry standard for working with a variety of materials used in today’s modern manufacturing environments. Laser processing generally means working with materials by means of cutting, engraving or welding. While there are numerous types of laser processing, we are going to discuss just one—laser engraving. Laser engraving is a valuable, highly desired type of laser processing, and when it is done well, it yields productive and stunning results.

Laser engraving is quickly becoming an industry standard for working with a variety of materials used in today’s modern manufacturing environments. Laser processing generally means working with materials by means of cutting, engraving or welding. While there are numerous types of laser processing, we are going to discuss just one—laser engraving. Laser engraving is a valuable, highly desired type of laser processing, and when it is done well, it yields productive and stunning results.

If you are wondering how laser engraving works, you are in the right place. On this page, we will cover the laser engraving basics, how it works, the different types of materials used, application tips and much more. If you have additional questions about laser engraving beyond what is covered on this page, please feel free to contact us. We have passionate, knowledgeable staff members with decades of experience and expertise with laser engraving. We would be more than happy to connect with you and discuss if laser engraving equipment can enhance or improve your current manufacturing needs.

Now, let’s start with the basics.

Chapter 1: What is Laser Engraving?

Laser engraving is a non-contact process where an optic assembly is moved over a surface in a side to side sweeping motion. The optic assembly includes a focusing lens which reduces the laser beam to a focal point. The focused laser beam delivers energy to the processing area in a manner which converts a high percentage of the light energy into heat. During engraving, the intense heat of the laser beam makes contact with the surface of a material, vaporizing it and leaving a permanent engraved area behind. It is normal for laser engraving to achieve a certain depth which can be modified by altering the engraving speed and power.

Laser engraving is a non-contact process where an optic assembly is moved over a surface in a side to side sweeping motion. The optic assembly includes a focusing lens which reduces the laser beam to a focal point. The focused laser beam delivers energy to the processing area in a manner which converts a high percentage of the light energy into heat. During engraving, the intense heat of the laser beam makes contact with the surface of a material, vaporizing it and leaving a permanent engraved area behind. It is normal for laser engraving to achieve a certain depth which can be modified by altering the engraving speed and power.

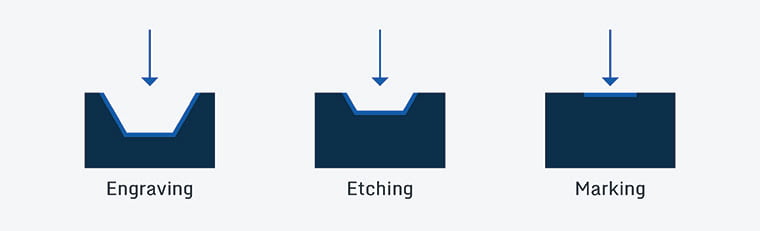

While you may have seen or heard laser engraving and etching used interchangeably, the truth of the matter is that there are distinct differences between the two. Yes, both applications create permanent changes to the surface of a material by the removal of material, but there is more to the story.

What Is The Difference Between Laser Engraving and Laser Etching?

The primary difference between laser engraving, laser etching and laser marking is depth—the depth of the engraved area left behind by the laser beam.

The term laser engraving is used when the removal of material is greater than .001” deep. Common examples of a laser engraved product would be checkering of a gunstock or deep engraving of a wooden sign.

Laser etching is the removal of .001” or less of material. Many products have a thin layer applied to them which is removed to leave a contrasting appearance. Coated metals are a great example of a product which can be laser etched to create personalized flasks, tumblers and other drinkware. Another great example of laser marking

Laser marking, on the other hand, does not melt or vaporize material. Instead, it uses a laser beam to create oxidation or a heat affected zone on the surface of a material, leaving behind a blackened or contrasting mark. Laser marking is popular for items like serial numbers, barcodes and logos. Additionally, marking sprays can be used to assist in creating a durable laser mark on material which may not be conducive to laser marking on their own. A very popular laser marking product is Cermark®.

How does DPI (dots per inch) affect laser engraving quality?

An engraving resolution or DPI (dots per inch) is set in the software. The DPI is used to set the amount of passes the laser beams make over a certain distance. Generally, a higher DPI results in a crisper and more defined laser engraving. 300 and 600dpi are two commonly used laser engraving resolutions that work well for most materials processed by lasers. As material is removed with laser pulses, images or engraved areas are created on the surface of a material. The processed areas are what form the final product.

An engraving resolution or DPI (dots per inch) is set in the software. The DPI is used to set the amount of passes the laser beams make over a certain distance. Generally, a higher DPI results in a crisper and more defined laser engraving. 300 and 600dpi are two commonly used laser engraving resolutions that work well for most materials processed by lasers. As material is removed with laser pulses, images or engraved areas are created on the surface of a material. The processed areas are what form the final product.

Advantages of Laser Engraving

- Non-Contact Process: Laser engraving is a non-contact process which eliminates the need for expensive tooling replacements. There is also no need to worry about snagging, ripping or pulling of the material being processed as the laser nozzle floats over the material without any physical contact.

- Flexible Capabilities: Laser engravers are capable of processing wood, plastic, natural stone, foam, textiles, paper, foil, cardboard, metal and just about any material you can get underneath the laser nozzle.

- High detail and accuracy: The laser beam is focused down to as small as .005” providing wonderful detail and the capability to engrave ultra-small font sizes.

- Easy design software: Engraving files are easily created without complex programming. Adobe Illustrator, CorelDRAW and Inkscape are just a few of the commonly used software programs that are compatible with Kern’s laser engravers. PhotoGRAV 3.0 software will quickly prepare high-resolutions images for laser engraving. Catalogs of laser-ready images can be purchased from various artwork suppliers.

- Multi-tasking: Once the laser system is in operation you are able to work on other projects that need your attention. A blinking light and audible job done alarm can be set to alert you when laser engraving is completed.

Chapter 2: Laser Engraving Basics

How To Laser Engrave

For those of you interested in laser engraving basics, we’re here to outline the five steps of the laser engraving process. They are:

- Ideate

- Design

- Choose settings

- Engrave

- Inspect

Ideate

Figuring out what you want to laser engrave can be the most time-consuming step. After all, this important step determines what you will need to do for the next four steps. When it comes to laser engraving ideas, the sky’s the limit. There are so many materials compatible with laser engraving. From stone and plastic to wood, leather and stainless steel, your options are wide open. In the next chapter, we will cover laser engravable materials in more detail.

Once you know your material, use your creativity to consider what you’d like to engrave onto the material. Is it an image? A phrase? Perhaps it is something more industrial like barcodes or a relief in the material required in the manufacturing process. Take some time to doodle on a notepad or search the internet for laser engraving ideas. We have included some ideas in Chapter 7.

Design

Once you know your material and what you’d like to engrave onto it, it’s time to design the image or text. The design for laser engravers is created on computer design software, so before you start, it is a good idea to ensure the design software you are using is compatible with your laser engraver software. Typically, you’re safe going with a popular design software like CorelDRAW®, Adobe Illustrator® or anything capable of outputting a .pdf file. Other commonly used file formats are:

- .ai

- .bmp

- .cdr

- .tif

- .eps

- .jpg/jpeg

- .png

- .gif

If your file format is in one of these listed, odds are your laser software will be compatible.

Choose Settings

All of Kern’s laser systems utilizes their proprietary KCAM laser engraving software. KCAM allows the user to easily adjust a variety of settings required for the engraving process. Within the software, you can control common parameters such as laser power, engraving speed and resolution (dpi). Over the past 30 years KCAM has evolved into one of the most advanced and powerful laser engraving software on the market. Odds are, if you need to make an adjustment to the engraving outcome, KCAM will have the ability to handle the job!

Kern provides material settings databases that will assist new users in determining correct settings based on your laser system setup and material being processed. Additionally, KCAM can save and load settings parameters so you can quickly move from material to material without a lot of testing of settings on scrap pieces.

For a brief run-through of what’s possible with laser engraving software, learn more about KCAM on its dedicated webpage.

It is always a good idea to give your engraving file one final look over. Look for common mistakes in your file such as misspelled words and missing elements.

Engrave

With the settings loaded into KCAM, it is time to place the material on the engraving table, turn the vacuum system ON, press the Start command and watch the magic begin! It is always a good idea to supervise the engraving process to ensure everything works as it should. Plus, watching lasers do their thing is very entertaining. Stand back, wear your safety glasses (when using Class 4 machines) and watch your design come to life.

Inspect

Take a look at your creation! Now that engraving is complete, you can remove the material from the laser engraver and give it an inspection. How are the quality of the lines and the clarity of the engraving? Does your creation match what you had envisioned? If so, make sure to save your KCAM parameter for future use.

Laser Engraving Tips

1. Focused and flat.

1. Focused and flat.

The optic lens which the laser beam passes through focuses the beam down to a small point. In most cases the focal point should be set to the top surface of the material being engraved. This ensures the smallest and most precise beam is removing material during the engraving process. Kern makes this process simple by setting the focus distance at a fixed position inside the beam delivery. A simple spacer tool is then used to set the gap between the nozzle and top surface of the material.

Generally, the best materials to engrave are those with a single flat surface. However, surfaces with slight variations or arcs in them can be engraved successfully. One example of a surface that is slightly uneven or arced is shown in the flask photo below.

However, some materials are more forgiving and will not show variation in focus. Wood is a good material where you can have some variation in flatness and still get beautiful results!

2. Take time for test engravings.

For materials that you are not familiar with or do not have a settings file, run a small test on a piece of scrap material to assess your settings. Usually, it only takes an inch or so of the engraving to let you know if the quality and clarity is up to your standards. Then, you can adjust the power, resolution or other miscellaneous settings before running the final job.

3. Choose a high-quality image.

One of the most common issues with laser engraving is image quality. If you start with a poor-quality image, it is almost impossible to get a good engraving. If there is any blurriness or pixilation, the engraving will not have sharp, clean lines.

Of course, best practices for laser engraving also depends heavily on the materials or products being processed. In the next chapter, we will cover a wide variety of laser engraving materials, including acrylic, wood, stone and glass.

Chapter 3: What is 3D Laser Engraving?

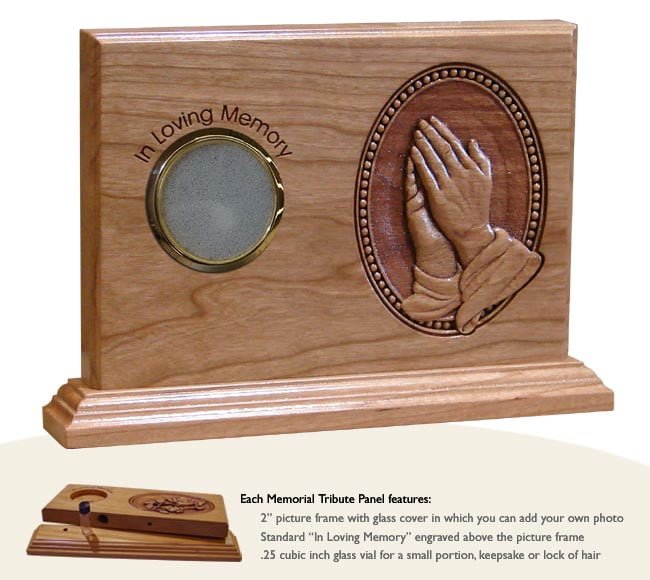

Kern is well known in the CO2 laser engraving industry for providing the most detailed 3D laser engraving system in the world! Kern’s 3D engraving technology has opened new avenues for artwork to be displayed on a variety of wood products. Designing 3D images takes some time but the end results will be breathtaking.

The Process

Designing 3D images generally takes more time than a standard 2D image, but the results are breathtaking and worth the time investment. Exactly 256 shades of gray can be interpreted by the KCAM software. That means there are 256 different power levels from black to white, which correlates to the 256 different levels of gray between black and white. This large spectrum of grayscales is what give the file a 3D like appearance. White is translated as 0% laser power and black would fire the laser at 100% power. Of course, the more power the laser engraves with, the deeper the relief in the material.

The key to 3D laser engraving is having a software that is capable of quicky adding grayscales to your artwork. CorelDraw is one such software where you can add grayscales based on a simple 0-100% scale.

The grayscale artwork below previews what a laser ready 3D image should look like. Kern’s KCAM laser software is one of the very few on the market which will accept true 8-bit or 256 different colors of gray for resolution.

The Gantry Co. is one such company that has been providing the finest 3D grayscale graphics to engravers since 1994. Check into the Partners Program which allows access to all 3D files available with substantial cost savings. For more information please visit www.gantryco.com.

The Results

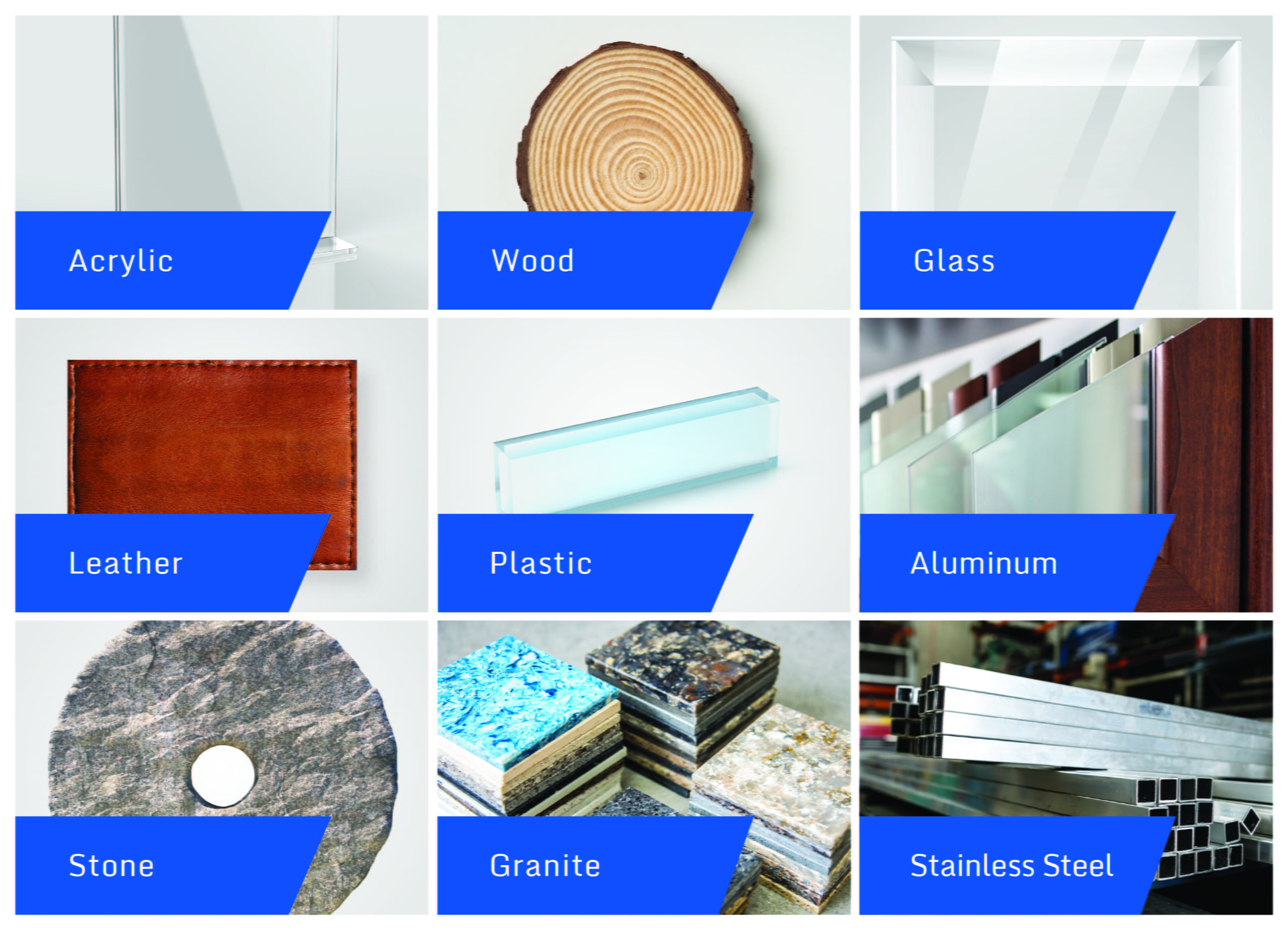

Chapter 4: Laser Engraving Materials

Laser engraving is a process that works on a wide variety of materials. From laser engraving granite to leather, there are plenty of materials to work with. In this chapter, we’ve outlined a handful of the most popular materials for laser engraving and provided some advice for successful engraving.

Acrylic

Acrylic

As one of the most popular materials used by laser operators, acrylic is an ideal material for laser engraving. One of the desired effects of laser-engraved acrylic is a white, frosted look on clear acrylic. Here are a couple of tips for getting great engraving results on acrylic.

Kern offers a wide nozzle option on their S-FOCUS optic assemblies. This wide nozzle opening allows the assist air to be dispersed over a larger area across the engraving, decreasing fogging or shadowing effect.

Also note that different brands and types of acrylic will grant different results. An old piece of acrylic can even engrave less desirable than a new piece. Make sure you know what material you are working with and make notes on the best vendors.

Glass

Glass

Laser etching glass with a CO2 laser can add stunning detail to a variety of items like mirrors, windows, wine glasses, and liquor bottles. As one of the less expensive materials for laser processing, glass is a great low-risk material.

One undesirable effect of laser etching glass is the occurrence of small micro fracturing left on the laser etched area. Here are two tips for dealing with this:

Etching on the back side of the glass ensures that the small micro fracturing that may occur on the etched surface are not accessible by anyone. Make sure you mirror your image before laser etching so that the image displays correctly when looking at it from the front side of the glass!

If etching on the top surface is required, a piece of newspaper can be used to remove the micro-fracture or glass shards that are left over from laser etching. Crinkle up the newspaper and rub the etched area in a circular motion. These tricks are inexpensive and easy to trial and require minimal clean up.

Leather

Leather

Leather is a material that responds well to laser engraving. Engraving adds customization and provides consistency to a wide range of leather products, including shoes, wallets, holsters, belts and purses. The types of laser-engravable leather are:

- Natural leather

- Suede leather

- Synthetic leather

- Vegetable Tanned leather

- Full-grain leather

- Bonded leather

Different types of leathers will have different results from engraving. As always, the quality of the material will impact laser engraving results. When working with a new leather type, always test your engraving on a piece of scrap leather to gauge processing settings.

Metals

Metals

There are two types of metal etching substrates: raw metal and coated metal.

Raw metals like stainless steel and aluminum can be successfully laser marked. Stainless steel can be marked one of two ways. The first method is to directly etch the metal with oxygen assist gas. The assist gas oxidizes the surface of the metal leaving a contrasting color. This may work well for industrial marking applications but is probably not the best option for medical or where food-grade marking is required. The other option is to use a marking spray such as Cermark®. Cermark can be applied to the metal surface in a tape or spray form. If using the spray, apply the coating and let it dry. Once dry, the laser will then be used to etch over this area and a durable and contrasting mark is left on the surface of the metal.

Coated metals like anoized aluminum and powder-coated steel can be etched directly. The laser will vaporize the coating leaving the raw metal as the contrasting mark. Coated metal products include the etching of flashlights, tags, phone covers, flasks, and labels.

Stone

Stone

Unlike human-made materials like plastic or glass, natural stone is, well, natural. As a result, it has unique characteristics that impact the overall quality and consistency of laser engraving. When laser engraving natural stone, it is beneficial to understand these characteristics.

Whether you’re engraving granite, marble, ceramics, porcelain or some other type of natural stone, the density and uniformity will impact the engraving process. As a rule-of-thumb, fine-grained, uniform stone will yield the most consistent results from laser engraving. When etching on granite and marble, the black-colored stone will allow for a white etch to be left behind.

Plastics

While plastics are a common material for laser engraving, not all plastics are compatible with laser processing. The most common plastics for laser engraving are:

- Silicone

- Acrylic

- Polyamide

- Polypropylene

- Polyethylene

- Polycarbonate

- Polyester

- Vinyl

Individual plastics will react differently to laser engraving. Some may create harmful gases, which can cause damage to the equipment or one’s health. Always ensure you know what you are cutting and review the SDS information before you process a new material. It is always important to have proper ventilation and air assist when laser engraving plastic.

Wood

Wood, like stone, is a natural material. Some woods respond to laser engraving better than others. Both hardwoods and softwoods have the ability to engrave well. Wood types that respond well to laser engraving include maple, cherry, birch and select white pines.

One thing operators need to look out for when choosing wood for laser engraving is knots. With a knotty wood, it’s more difficult to get consistent engraving because the knots are harder than the rest of the wood. So, when you’re running a file, you’re going to get a different look over the knots than over the other parts of the wood.

Also, wood for laser engraving must be properly planed to provide the laser with a flat, consistent surface. Without this, the results of laser engraving will not be uniform and consistent.

Other Materials For Laser Engraving

While we’ve covered some of the most popular here, there are many more materials suitable for laser engraving. We invite you to send us any materials you have that you’d like to see laser-engraved. Once we receive and process them, we will ship them back to you so you can see the results for yourself. Are you interested? You can start the process here.

Chapter 5: Choosing The Right Laser Engraving Machine

Choosing the right laser can seem complicated at first until you know which variables to consider. In this chapter, we’ve included a laser engraving wattage comparison chart, along with some helpful information about laser beam power settings and processing speed. As always, if you have any additional questions about choosing the right laser, please contact us.

Laser Engraving Equipment Wattage Chart

Class II (Enclosure) | Class IV (Open Bed) | Table Size (Inches) | Available Wattages | Rotary Option Compatability | K-Vision Camera Compatibility | Metal Cutting Option Availability | |

|---|---|---|---|---|---|---|---|

* Custom Sizing Available | |||||||

OptiFlex | 52×50 – 86×144* | 100W-650W | Y | Y | Y | ||

EcoFlex | 52×50 – 52×100 | 100W-250W | N | Y | N | ||

Micro | 24×24 – 48×24 | 100W – 650W | Y | Y | Y | ||

OptiDual | 52×50 – 86×144* | 100W – 200W | Y | Y | Y | ||

LaserCELL | 52×50 – 52×100 | 100W -650W | Y | Y | Y | ||

Laser Engraving Wattage Comparison

Kern’s CO2 laser systems can be equipped with lasers from 100-650 watts. Wattage determines a laser’s power. Higher wattages mean a more powerful laser, and lower wattages mean a less powerful laser. There is some misconception that a higher wattage laser can be too powerful for certain applications, but it’s worth noting that high-wattage lasers can be programmed to use a smaller percentage of their power.

For instance, our 400W laser source can be dialed down to etch on even the most delicate of substrates like cardstock. The same 400W laser can be setup to cut through a 1” piece of acrylic with just some modifications to the KCAM laser settings.

Kern Laser Engraving Speeds

Due to high speed servo motors laser engraving speeds on Kern’s laser systems range from 25 inches-per-second to 150 inches-per-second. If laser engraving speed is an important factor for your machine choice, then you will want to consider our high-performance line of lasers which include the OptiFlex and LaserCELL.

Chapter 6: Accessories & Supplies

Laser Engraving Machine Accessories

Laser system accessories and attachments help owners and operators expand their capabilities and improve their output. Below, we’re describing some of the most popular system attachments and options: k-vision camera registration, pipe rotary and metal cutting.

K-Vision Camera Registration

The k-vision package is a fully integrated hardware and software solution that allows for accurate cutting of preprinted materials. This process starts with a nozzle-mounted camera which automatically measures the dimensions between registration marks on printed materials.

The system then uses these measurements and the registration marks of the original cutting file to compensate for distortion and rotation. The slight adjustments that k-vision makes to the cutting file results in a perfectly matched cutout in the material being processed. The entire camera system can be easily removed and stored in a protective box when not in use.

Wheel And Pipe Rotary

A z-axis rotary attachment outfits a laser system with the capability to process pipes, rods and other cylindrical items. Without a rotary attachment, laser engraving can only be done on relatively flat surfaces, but with the attachment, an entire world of possibilities opens up.

A laser system with a rotary attachment is able to engrave objects like walking sticks, canes, liquor bottles, and flashlights.

Metal Cutting

The metal cutting laser option makes it possible for CO2 lasers to cut a whole host of metals. You might ask why is the metal cutting system beneficial for laser marking? The metal cutting option includes a height following system which allows the laser beam to stay in focus over the entire metal sheet. When considering focus, metal is much less forgiving than materials like wood and plastic. The height follower can be used when engraving to allow for full table marking of aluminum, mild steel, and stainless steel.

This metal cutting option was developed internally by the team at Kern Laser Systems, and it is compatible with four out of five CO2 lasers in the Kern lineup. They are:

With any of these options—vision cameras, pipe rotary, or metal cutting—operators can outfit their laser system with the engraving capabilities to take on complex projects.

Laser Engraving Supplies

When you think of laser engraving supplies, it’s common to think of raw materials like sheets of glass, one-inch thick acrylic, sheets of plywood or metal. These raw materials are popular laser engraving supplies, but they’re not the only options. Another popular choice is engravable blanks.

Engraving blanks, which are pre-made products that come ready for laser processing, are available in almost anything you can think of. From pint glasses and hunting knives to ornaments, keychains and license plate frames, you can find a laser-ready version. Engraving blanks are a great way to add personalization through laser engraving in a simple, yet relatively inexpensive, way.

Many laser engraving supplies and parts are available from the LaserLocker.com website.

But pre-made products are just the tip of the iceberg when it comes to what can be achieved with high-power CO2 laser engraving. In the next chapter, we will discuss projects and ideas for laser engraver machines.

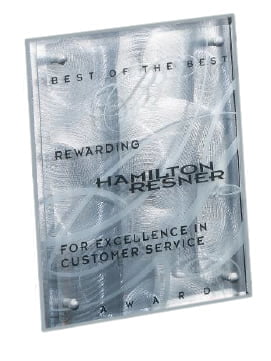

Chapter 7: Laser Engraving Applications

Do you have some laser engraving project ideas in mind? When it comes to laser engraving projects, you’re truly only limited by your own imagination. For those of you looking for laser engraver project ideas, we’ve provided some examples from our very own customers. Each laser-engraved item you’ll see in the next section was processed on a Kern laser system. We hope this next section leaves you feeling inspired and full of ideas for your next project.

Laser Etching Applications

Laser Marking Applications

Plaques & Awards

Signage

Kitchen Platters & Cutting Boards

Display Cases

Musical Instruments

Artwork

Tap Handles

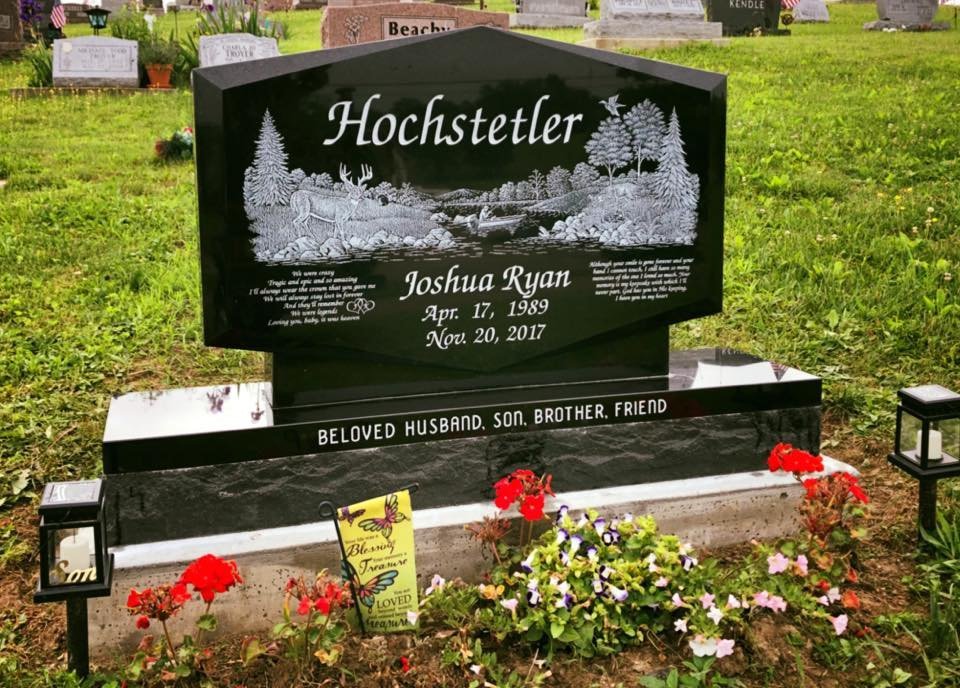

Memorials & Headstones

3D Laser Engraved Signage

Home Decor

Urns

Learn More About Laser Engraving

While we’ve covered a whole lot about laser engraving here, there is so much more to know. If you have any questions, whether they are application-specific or not, please do not hesitate to contact the friendly, knowledgeable staff here at Kern Laser Systems. You can contact us here or request a samples kit! We’d love to hear from you.

Thank you for reading, and we hope you have a great day!

Acrylic

Acrylic Glass

Glass Leather

Leather Metals

Metals Stone

Stone