Laser Cutting Labels, Nameplates & Tags

Metal & Plastic Identification Labels

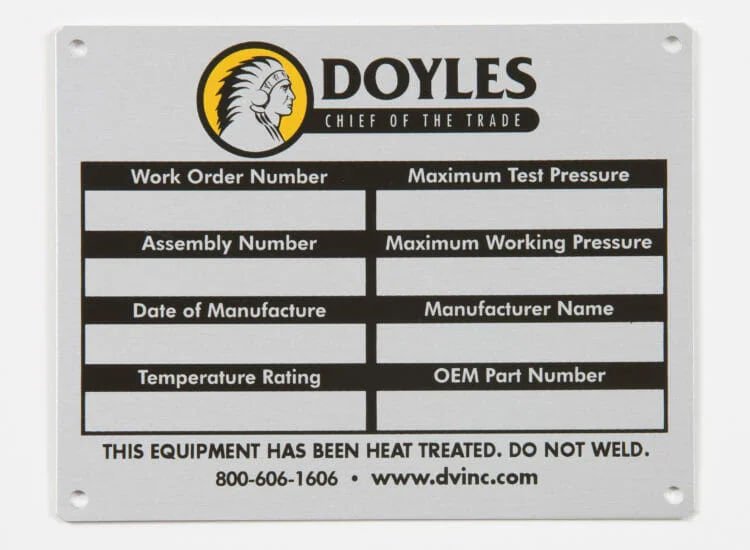

Labels and tags are a widely used and durable method of equipment and asset identification. Cutting and etching of customized tag is an application in which CO2 and fiber lasers excel at. A wide range of materials can be used to create professional looking labels, tags and nameplates. Generally, the installation environment determines the proper material choice.

The k-vision camera package can be used to precisely cut pre-printed sheets to shape and size.

Many of the tags, labels and nameplates that are shown on this page were created by Metal Marker Manufacturing Co. located in North Ridgeville, Ohio. Metal Marker utilizes Kern’s MICRO 650W laser system to create tags and labels for a variety of industries.

Benefits of a Laser System

Acrylic by nature can scratch easily if not handled properly. Laser cutting and engraving is a non-contact process, allowing acrylic to be cut without tooling which comes in contact with the material and can damage the surface of the acrylic.

Kern’s CO2 lasers cut acrylic with a single pass of the laser beam resulting in a flame polished edge quality that does not require post processing steps such as buffing or manual flame polishing of the processed edge.

The CO2 laser beam has a kerf as small as .005″, allowing parts to be nested tightly together maximizing sheet yield and reducing waste. Nesting software is available which will automatically nest complex parts together saving you money on each job you run.

Adhesive Backing

Many aluminum nameplate manufacturers are running 500W laser systems to cut thin gauge aluminum tags and labels with great success. CO2 lasers are generally more effective than fiber lasers for cutting aluminum labels with an adhesive backing because of their longer wavelength, which is less absorbed by the metal and more effectively interacts with the adhesive layer. This allows the CO2 laser to cleanly cut through both the aluminum and the adhesive without excessive damage to the material. Moreover, the CO2 laser’s beam quality and precise control enable it to delicately handle the layered structure of these labels, ensuring a cleaner edge and reduced risk of burning or warping the aluminum or adhesive.

It is important to test which type of laser source (CO2 or fiber) achieves the best cut quality of the metal sheet and the adhesive backing. Kern’s applications team is happy to test your exact material and send it back for your analysis. To test your material please fill out of Test Your Material form and get the process started!