Laser Fabrication

Dashboards

Dashboards in automobiles and aircrafts can be manufactured by means of laser cutting and engraving.

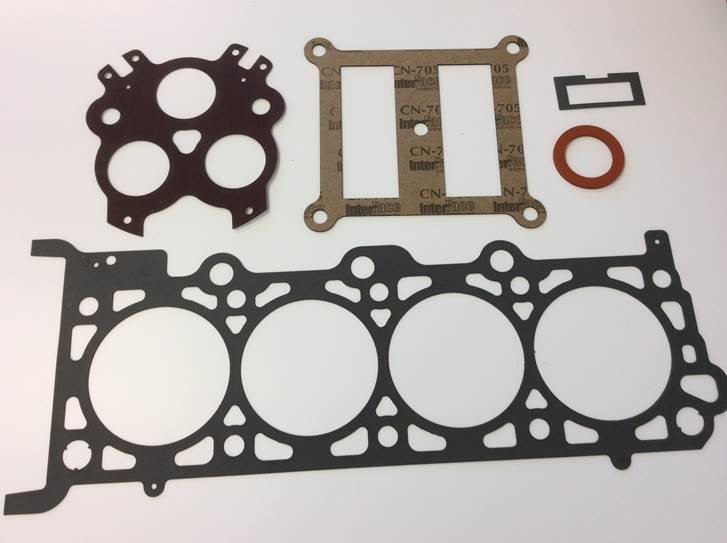

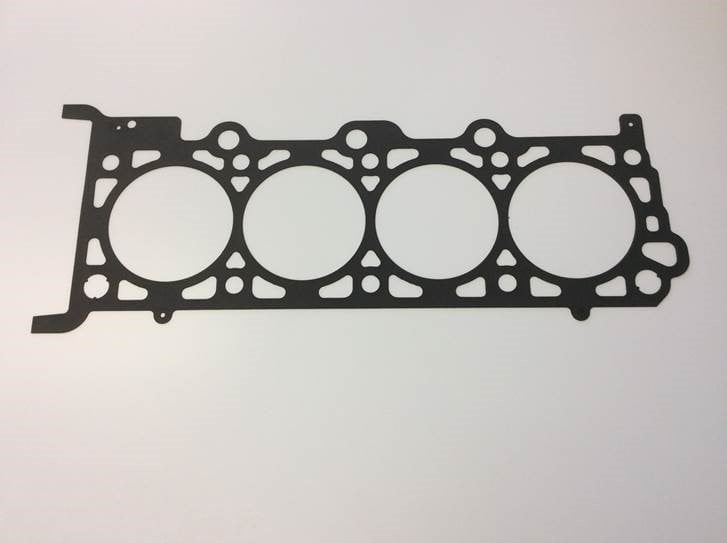

Gaskets

Gaskets for engines and other machines can be manufactured by means of laser cutting and engraving.

FOAM TOOL KITTING

A Kern Laser will help to organize your tools by shadowing them with tool foam. Utilizing tool foam can greatly reduce the amount of time that you spend looking for misplaced tools and increase your manufacturing and workplace efficiency. Cutting tool foam is so easy that we use it for our own laser tool kits that come with each laser system.

THE SIMPLE TOOL FOAM SHADOWING PROCESS:

- Use a scanner/lightbox with a camera to import the tool image into your design software.

- Utilize the trace feature to create a vector outline of your tool.

- Send the cutting file to the laser with Kern’s easy to use Laser Printer Driver.

CONTROL PANELS & ELECTRICAL PANELS

Control panels are used in a variety of places from medical equipment to CNC machinery. Kern’s metal cutting systems are capable of cutting notches, slots and other cut profiles that are often required in control panel manufacturing. For a majority of manufacturers a large kW size laser is not required to process the thin gauge metal that electrical panels are made from. Kern’s economical 250W and 400W lasers are allowing shops of all sizes to bring their metal fabrication in-house.

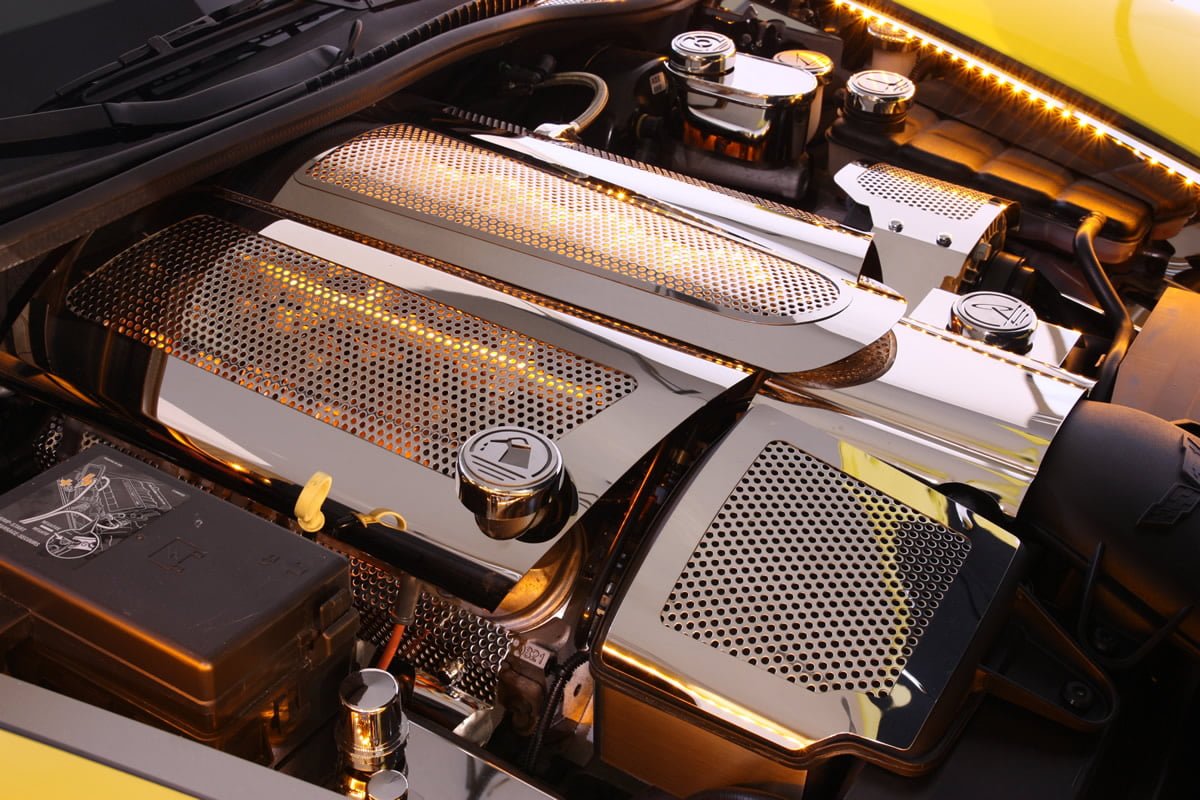

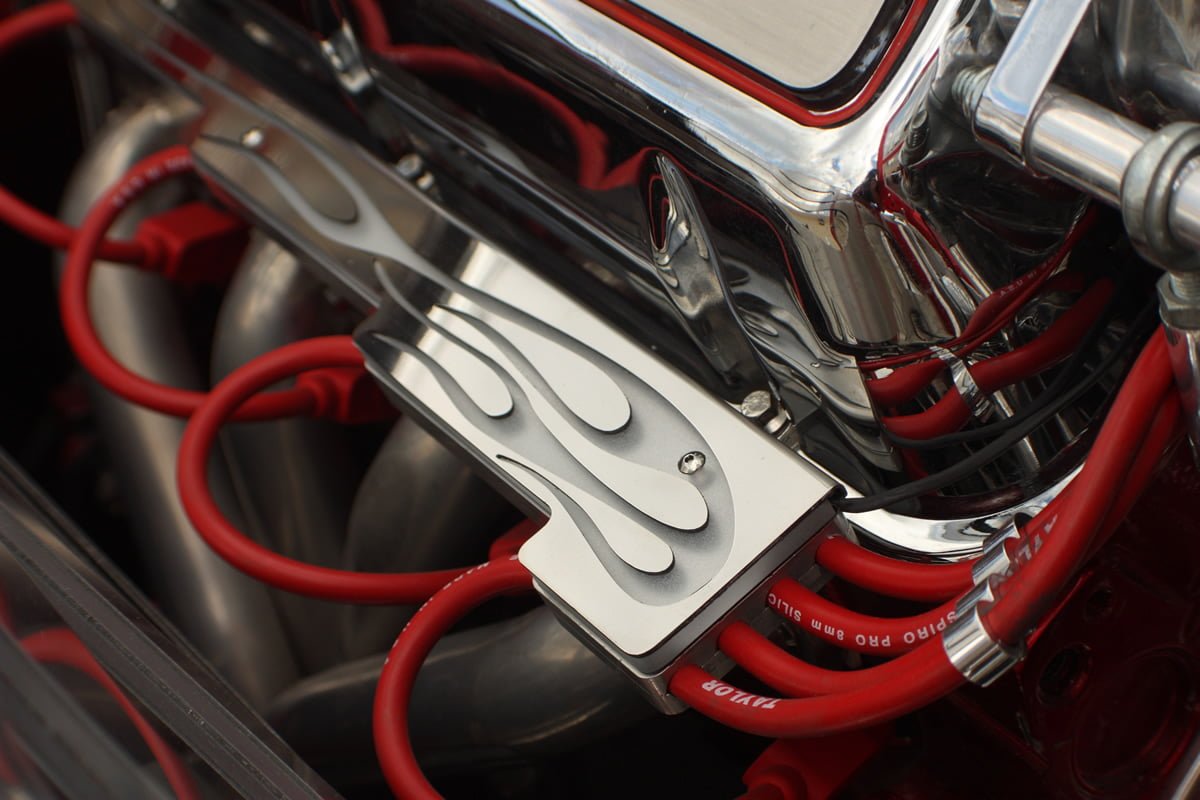

AUTOMOTIVE PARTS

Grills, motor covers and custom dash kits are just a few of the automobile accessories being produced by Kern Laser Systems.

Benefits of using a Kern laser for Fabrication

Cut Optimizer. Decrease your programming time by letting KCAM automatically determine the fastest cut order for your most complicated designs.

Time Estimator. Provide accurate pricing to your customers by knowing the amount of laser processing time before the product even makes it to the laser bed.

Tool Offset. A simple inside/outside offset can be set to compensate for the laser beam kerf. This results in precisely sized parts without modification of your original part drawings.

Customized Pierce Settings. The dwell time, laser power, frequency, focus point and air flow can be set independently from your normal cut settings. This feature ensures metals are cut clean with minimal to no dross.

Air Control. Compressed shop air, oxygen or nitrogen can be hooked up to the laser system for optimal processing results on a variety of laserable materials.

Vector Path Speed Control. KCAM mimics a race car by slowing the cutting speed into sharp corners and accelerating out of them. The result is smooth, consistent cutting with the tap of your mouse.

Laser Printer Driver. An easy to use Laser Printer Driver links KCAM to commonly used design software such as CorelDRAW® and AutoCAD LT®.

Vision Registration System. K-Vision is a fully integrated hardware and software solution that turns your laser cutting table into an advanced digital finishing system.

G-CODE capable. Are you used to programming with GCODES ? No problem! KCAM’s built in GCODE converter allows you to continue working with your preferred CAM software to generate .NC files that are loaded directly into KCAM.