Mild Steel Laser Cutting

Mild Steel CNC Laser Cutter

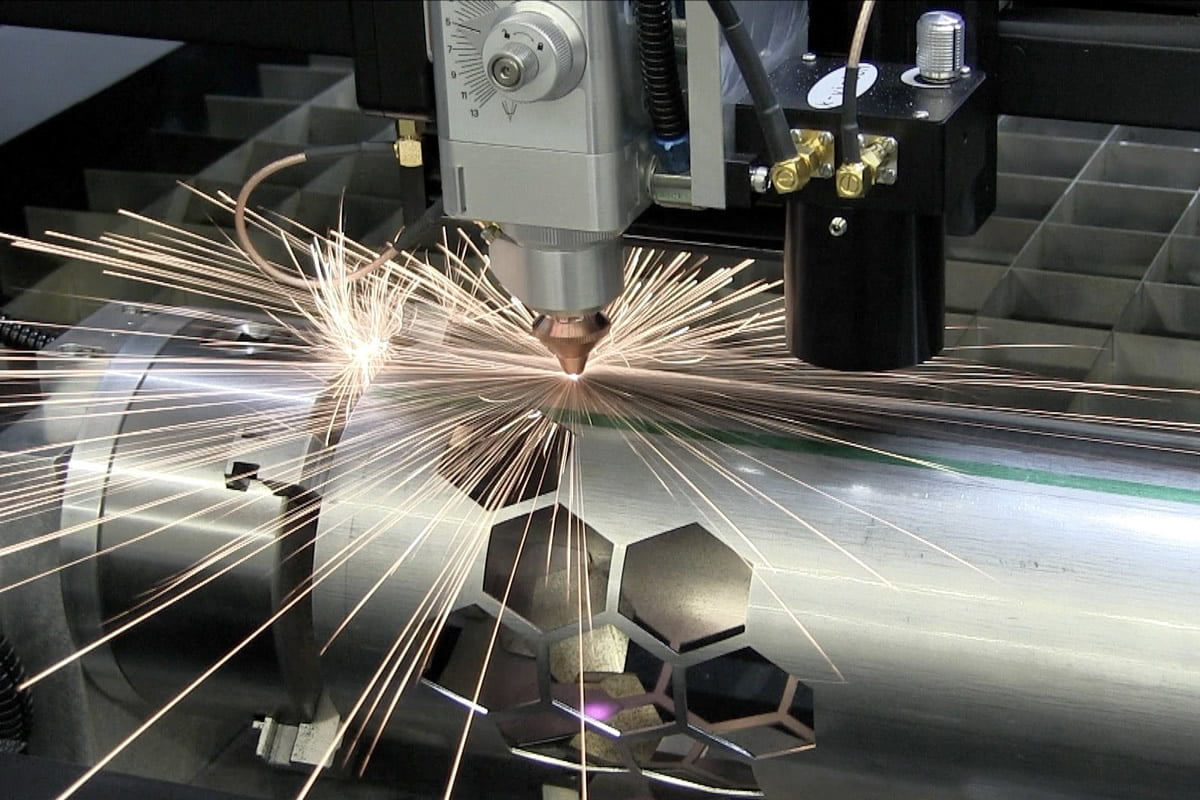

Kern’s CO2 and fiber metal cutting machines are capable of laser cutting mild steel. A high-pressure air assist injects oxygen through the optics nozzle resulting in a clean and smooth cut. CDA (clean, dry air) can be used on thinner gauge steel to reduce the cost of laser processing.

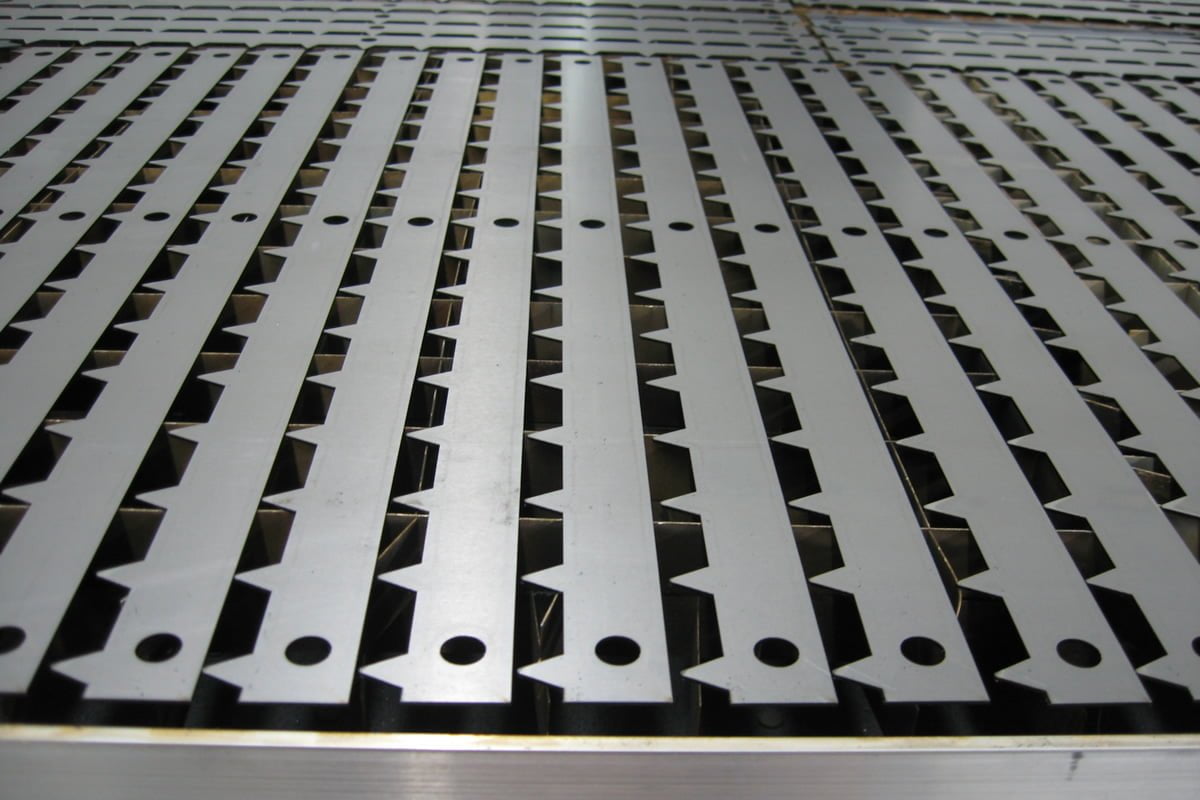

Mild steel, or cold rolled steel, is one of the more commonly laser-cut materials in the industry. Laser cutting is a flexible, stress-free process that produces quality finished parts with little or no post-processing. Cutting begins when the metal is heated to its melting point, resulting in a clean edge and dross-free cut. Lasers create narrow kerf lines and achieve a highly accurate cut, resulting in minimal material waste.

Laser cutting can be used for a variety of metals, including mild steel. Starting with Kern’s CO2 lasers of 100 to 650 watts, mild steel can be cut at varying thicknesses up to .250″. Fiber lasers are available with up to 3kW’s of power and will process mild steel as thick as .375″.