Brass Laser Cutting

Brass

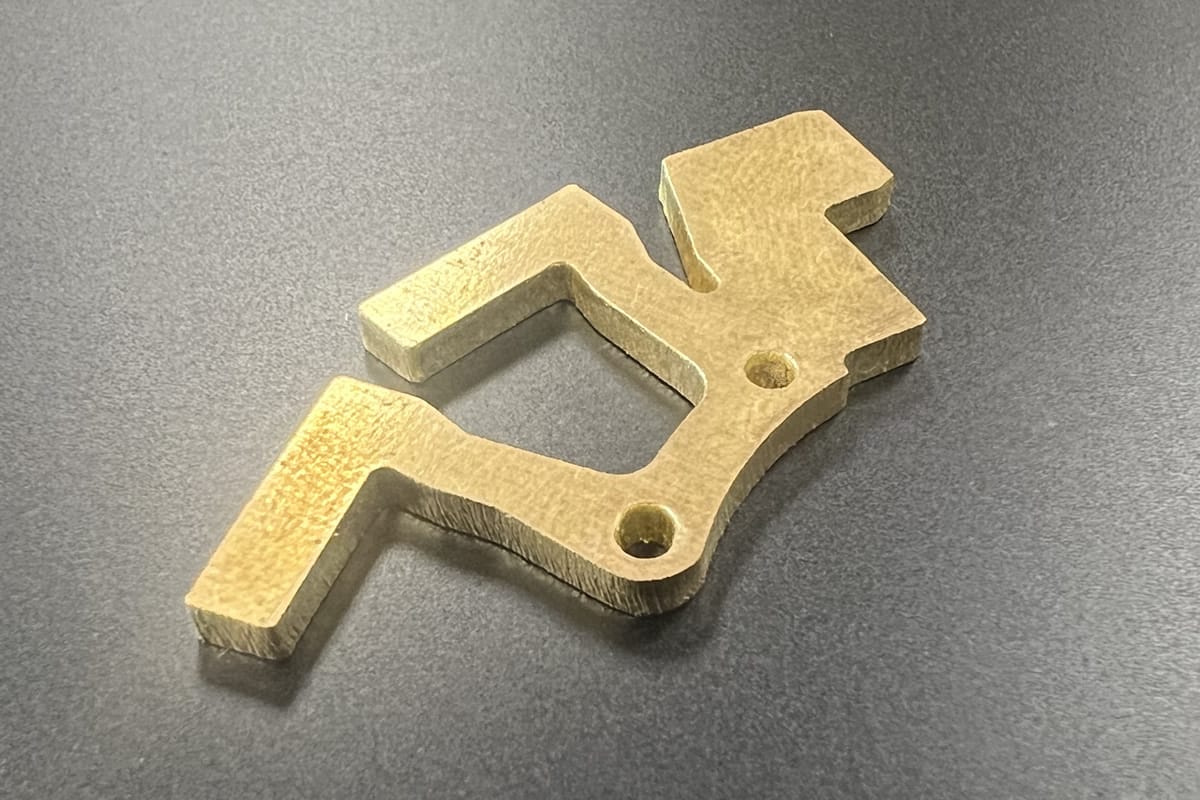

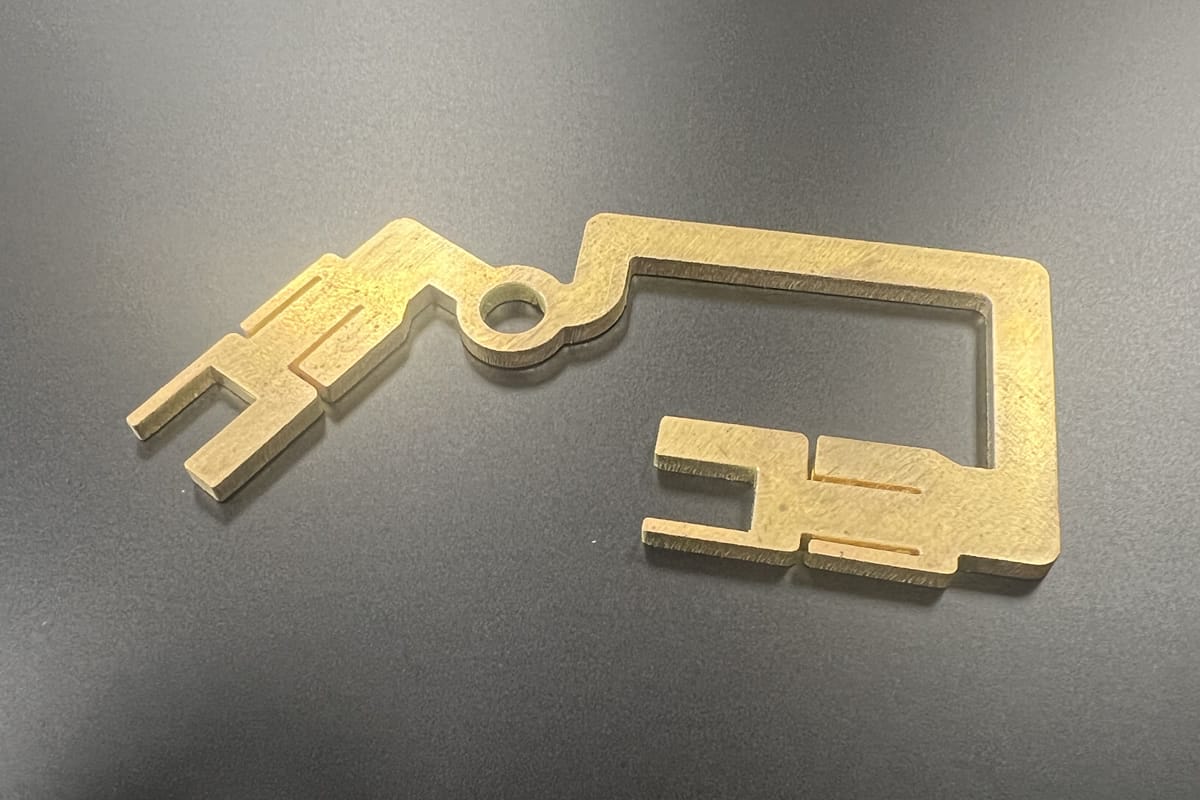

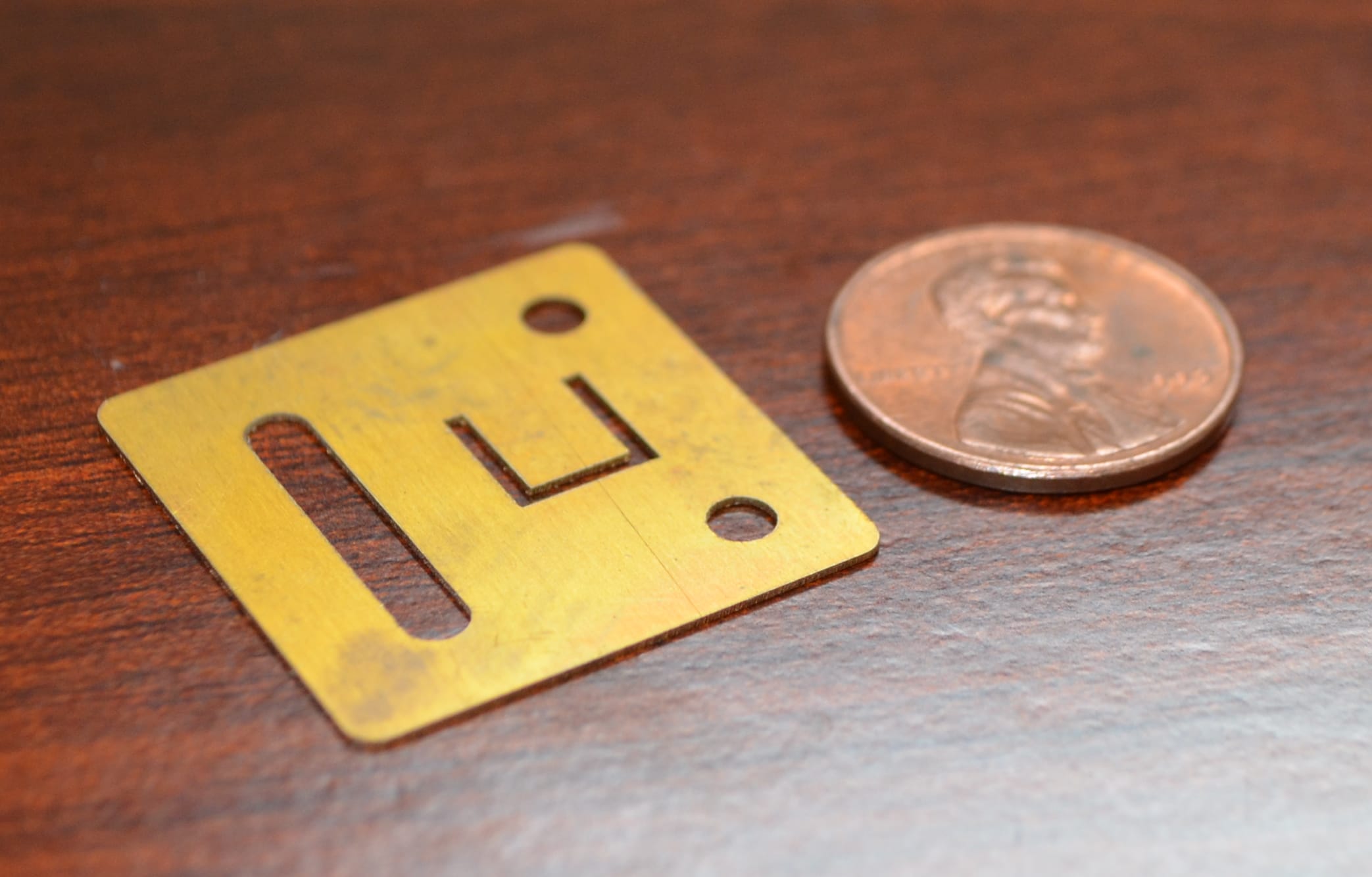

Cutting brass with a laser is a highly efficient and precise process, leveraging the power of laser technology. This method allows for clean and accurate cuts on brass materials, making it ideal for intricate designs and industrial applications. The laser’s focused beam minimizes material wastage and enhances cutting speed, offering a superior alternative to traditional mechanical cutting methods.

COMMON APPLICATIONS

Jewelry Making

Industrial Components

Electrical Components

Architectural Panels

Decorative Items and Artwork

Musical Instruments